-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Case Studies

Promoting product recycling efforts in Japan

As an enterprise with official designation for wide-area industrial waste disposal in Japan, Fujitsu engages in various kinds of contracts for accepting industrial waste for appropriate processing.

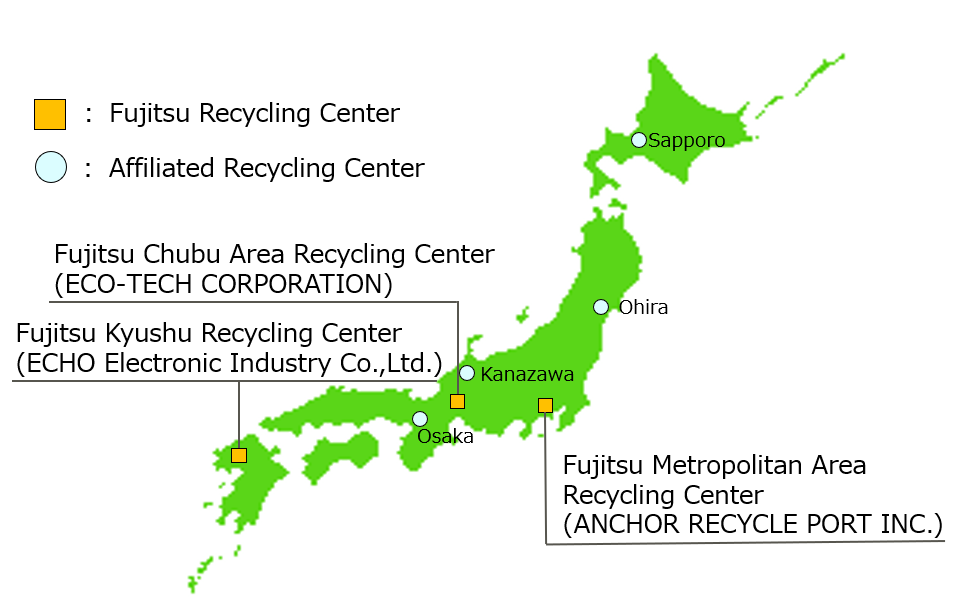

We have established Fujitsu recycling centers throughout Japan to create a nationwide recycling system. This system provides for rigorous traceability and security, and achieves a high resource reuse rate. By providing this safe and secure service, we are fully discharging our Extended Producer Responsibility (EPR).

Providing Product Recycling Information

In order to properly dispose of end-of-life ICT products, since FY2004 Fujitsu has been operating a digital management system for its product disassembly manual.

Through this system, Fujitsu recycling centers can download from our website, as animated disassembly manuals, all the information they need to recycle products. The system also provides instructions on how to deal with items containing restricted chemical substances and plastic materials, and with products that contain customer data.

Promoting Recycling

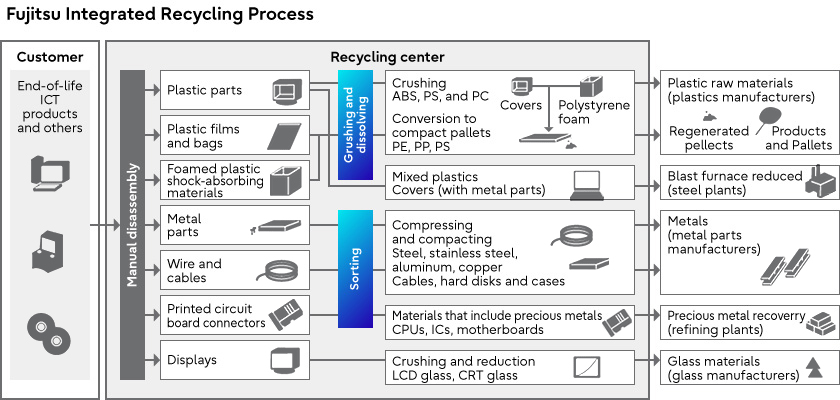

Collected products are carefully dismantled by hand by skilled workers and separated by materials such as iron, copper, aluminum, precious metals, glass and plastic. We are also working to improve the level of manual dismantling by utilizing video dismantling manuals. In this way, we are working hard to reduce waste as much as possible and to reinvent our products as resources for making them.

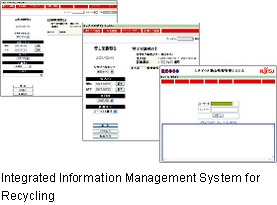

Developing a Traceability System

We developed an integrated recycling information management system and since FY 2007 have adopted it at the Fujitsu recycling centers.

Using this system prevents theft and illegal dumping by attaching barcodes to customers' ICT products and managing data on the history of the recycling process from acceptance at the recycling center through disassembly and destruction of the hard disks on a per-customer basis.

Operation of Security Systems

A high level of security is maintained at Fujitsu Recycling Centers by using infrared cameras to monitor automatically for intruders and check the storage status of the accepted products.