-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Product Recycling

Our Approach

The Fujitsu Group's product recycling programs are based on Extended Producer Responsibility (EPR) and Individual Producer Responsibility (IPR). EPR holds that producers bear responsibility for products, from design and manufacturing to disposal and recycling. IPR holds that producers bear responsibility for their own products. IPR in particular has been a major challenge for the Fujitsu Group as we expand our business globally. However, we believe that responding to this challenge, and that of EPR, in collaboration with industry associations and governments, will allow us to help create a recycling-minded society that meets the requirements and demands of all stakeholders.

The Fujitsu Group thus carries out recycling programs that comply with the laws and regulations of the various countries in which it operates.

In Japan, Fujitsu is certified under the Industrial Waste National Permit System, which is based on the Act on the Promotion of Effective Utilization of Resources, and as such, accepts industrial waste and puts them through appropriate processing at Fujitsu recycling centers across Japan. We also try to do as much collection, reuse, and recycling as we can, even in countries where recycling is not obligatory.

FY 2020 Performance

| Targets Under the Fujitsu Group Environmental Action Plan (Stage IX) | Last fiscal year (FY2020 result) |

|---|---|

| Maintain over 90% resource reuse rate for business ICT equipment at Fujitsu recycling centers. | Achieved a 91.6% resource reuse rate. |

Promoting Recycling of ICT Products

The Fujitsu Group has built a recycling system that covers the entire country of Japan. We have worked steadily to implement Extended Producer Responsibility, providing safe and secure services with high resource reuse rates in order to promote the recycling of ICT products. We have, at the same time, also ensured thorough traceability and security of these processes.

Achieved a 90% or Higher Reuse Rate

We processed 2,991 tons of recycled ICT products (used ICT products for business applications) from corporate customers in Japan, and achieved a resource reuse rate of 91.6%. We have now also collected a total of 67,185 end-of-life PCs from individual customers.

Changes in Resource Reuse Rates of End-of-Life Business ICT Products (Japan)

| FY | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|

| Resource reuse rate(*1)(%) | 91.5 | 91.7 | 91.1 | 91.6 |

| Amount processed (tons) | 3,844 | 3,436 | 3,210 | 2,991 |

- (*1)Weight percent ratio of recycled parts and materials to end-of-life products.

Changes in Numbers of End-of-Life PCs Collected from Individual Customers (Japan)

| FY | 2017 | 2018 | 2019 | 2020 |

|---|---|---|---|---|

| End-of-life PCs collected (units) | 59,144 | 53,481 | 58,560 | 67,185 |

Examples of Initiatives in FY 2020

Helping build a sustainable future in the UK: Collaborative recycling projects with Heathrow Airport

Removed fiber cabling

Removed fiber cabling

Fujitsu UK worked collaboratively with Heathrow Airport on two significant projects to help build a more sustainable future and help update Heathrow’s environmental standards. Together Fujitsu and Heathrow removed and recycled 24,250kg of fiber cabling. By updating the existing fiber standards to new Glass Reinforced Polymer (GRP) fiber cabling, this decreased the environmental impact of manufacturing Steel Wired Armoured (SWA) Cable, and also reduced chemical impact deployed at Heathrow.

Supporting the Development and drive of sustainable water treatment, the Eastern Balancing Reservoir Project installed the longest single runs of new sustainable and non-toxic fiber cable across the airfield. The non-stop fiber replaced 10km of legacy copper cabling, of which all 11,354kg was then recycled.

The circular nature of these collaborations generated a sum for the Heathrow Community Fund of £15,318. This gave enough funding for 6 community projects. As an example, the ‘Digital Inclusion’ project trained adults with learning disabilities in how to use computers and provided work experience within their community shop. This project also refurbished unwanted computers, taught the clients how to sell them online to make a profit, which then helps the scheme to continue.

Other community projects included The Older people’s festival which funded 9 new raised beds for elderly gardeners, The good company Café, Change R&R and Feltham in Bloom were all assisted from the money generated from recycling the fiber and copper cables.

Computer training through the ‘Digital Inclusion’ project

Computer training through the ‘Digital Inclusion’ project Presentation of the Heathrow Community fund by CEO John Holland-Kaye

Presentation of the Heathrow Community fund by CEO John Holland-Kaye

(far left) and Stuart Birrell CIO (far right)

“I also love the ‘circular’ nature of the collaboration – replacing old, unwanted IT infrastructure generates income to fund training for adults with learning disabilities in skills which enables them to recycle and sell old unwanted computers, and hence get into employment . The project really demonstrates the huge improvement in local communities that can be made by just pausing at the start of a piece of work and thinking ‘right, how can I maximize the benefit of this project.”

Quote from HCT Director Dr Rebecca Bowden

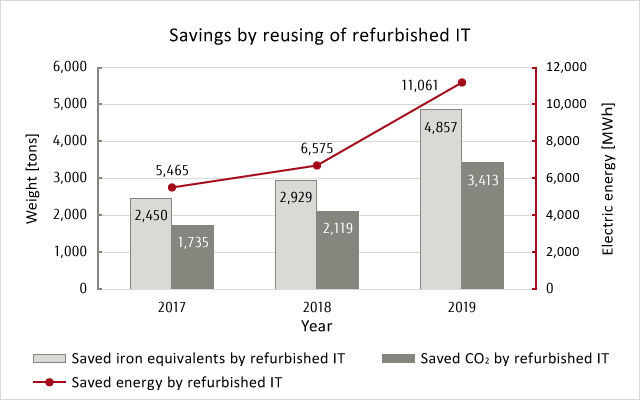

Refurbishment(*2) and Remarketing of old IT equipment in Germany

With 20-years of recycling experience Fujitsu Technology Solutions (FTS) in Germany has a recovery rate of more than 90% with its take-back products, considerably more than the 75% in the legal direction. FTS have set ambitious KPIs for Refurbishment and Remarketing of old IT equipment inline with Fujitsu’s Global environment. Our commitments looks further to collaborate with diverse companies that positively impact society. FTS have an agreement with a refurbishment and recycling partner “AfB – Arbeit für Behinderte – Work for disabled people”. AFB is a large non-profit IT company, specialised in the extension of product lifecycles of used IT and mobile devices through high-quality refurbishment and remarketing. They offer multi-faceted jobs for people with and without disabilities. All of their work steps are designed barrier-free, promoting people’s potential and helping them realize their professional and personal goals with an optimum work-life balance. Throughout our partnership with AFB, Fujitsu have sponsored 63 jobs for people with disabilities over 2019 have contributed to saving 4,856,647 kg of iron equivalent resources and 3,413,304 kg of CO2 equivalents. 82 % of the devices collected from Fujitsu could be remarketed following data destruction, hardware testing and refurbishment.

- (*2)Refurbishment means that the manufacturer replaces deteriorated parts such as initial defects and used products and refurbishes them to make them look like new products. This is recommended as a resource utilization model in the circular economy.