-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals for FY2025

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Occupational Health and Safety

Health and Safety Policy

The Fujitsu Group has established a Health and Safety Policy for conducting various business activities, and we promote group-wide efforts to set up safe, pleasant working environments and create a workplace culture that will ensure the health and safety of our employees. Health and safety policies and initiatives are reported and shared with members of the Executive Management Council and the Board of Directors, and communicated to all employees.

Fujitsu Group’s Health and Safety Policy

Ensuring the health and safety of Fujitsu's employees is one of the most important management topics, and it is given the highest priority in all of Fujitsu's business activities.

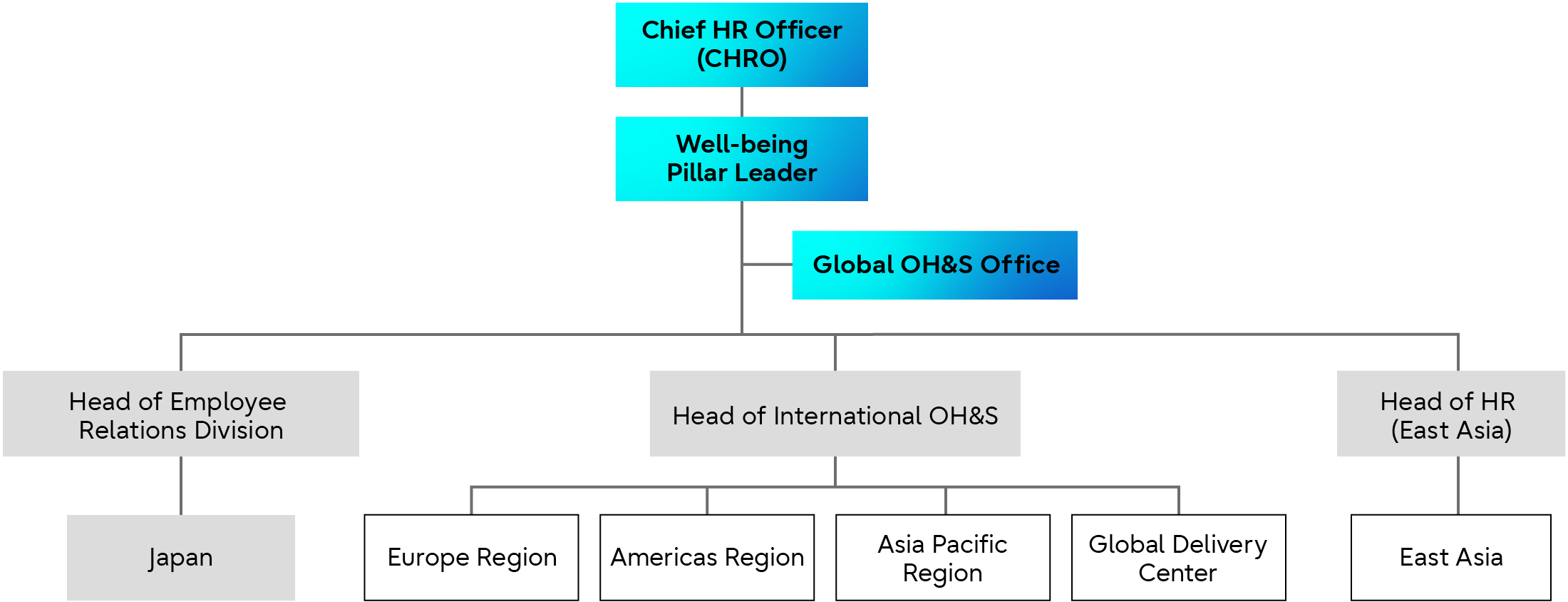

Promotion Framework and Reviews

The Fujitsu Group has established a system to promote health and safety in each region, and we are moving forward to ensure compliance and preventive measures for occupational health and safety in accordance with the laws and policies of each country, such as those stipulated by the Ministry of Health, Labour and Welfare, ILO, etc., through a comprehensive, region-led approach.

We have set up the Central Health and Safety Committee in Japan, which is comprised of the representatives of the Human Resources and Corporate Affairs Unit, Health Promotion Unit, and representatives and others from the Labor Union to function as an overseer for the Health and Safety Committees at each business site. The Central Health and Safety Committee meets once per year to share information and report to management and those in charge at each location about the confirmed status of disasters that occurred at business sites and implement preventative measures, while also formulating Group-wide health and safety related policies.

In addition, the health and safety management organizations at individual business sites, comprised of staff from the Human Resources and Corporate Affairs Unit and representative of each business site, hold monthly Health and Safety Committee meetings. These committees establish policies suited to the unique characteristics of each site, set priorities, and work to create healthier, safer workplaces in accordance with policies related to the occupational health and safety. In addition, these health and safety management organizations conduct regular workplace patrols, survey for potentially dangerous areas or causes of health hazards and factors based on a workplace inspection checklist, and report on improvements, and conduct risk assessments. They also post response methods on each business site’s intranet as a preparatory measure for emergencies.

The Human Resources Unit has a workplace management inquiry system and workflow for promptly reporting workplace accidents, and responds to inquiries and consultations from employees at any time.

In the Europe, Americas, Asia Pacific regions and at the Global Delivery Center, we hold health and safety leadership forums three times a year for the purposes of monitoring and examining occupational health and safety activities at the regional and national levels, as well as report on strategic goals, achievements and ongoing improvements in occupational health and safety at the regional and national level to foster a culture that does not tolerate occupational accidents in the workplace.

Structure for Promoting Occupational Health and Safety

Structure for Promoting Occupational Health and Safety

Fiscal 2023 Results

The Fujitsu Group aims to achieve zero occupational accidents, implementing various measures to create a safe and comfortable working environment at all workplaces and promote mental and physical health. Specifically, we provide information on health and safety, offer training opportunities to promote awareness towards health and safety and take steps for the prevention of occupational accidents, as well as encourage employees to develop exercise habits and take preventive actions against accidents. Furthermore, we also strive to maintain and improve the quality of our activities, including acquisition of international certifications. The details of our initiatives aimed at improving employee safety and health are reported and shared with the Sustainability Management Committee, which meets semi-annually.

Occupational Health and Safety Training

We provide health and safety training, as well as health education that raises health awareness, for the entire Group and for the unique environments at each office. In particular, industrial physicians and counselors send messages as necessary in regard to topics such as lifestyle diseases and various vaccinations, and physical and mental health maintenance in order to raise employee awareness.

We also utilize Fujitsu Learning Experience to create an environment where anyone, at a global level, can learn anytime with initiatives suited to the circumstances of each region and country.

In Japan, health and safety education is provided via e-learning to new employees of Fujitsu or Group companies to acquire useful basic knowledge on occupational accident prevention and self-management of health (2,196 people/year complete the course).

In the Europe region and at the Global Delivery Center, online training (Safety Awareness World, City Safety Challenge) allows employees to experience various work environments around the world for the purpose of understanding and properly managing workplace health and safety risks. This training also contributes to spreading the use of support tools aimed at ensuring safety at all workplaces. We also conduct specific training and campaigns in specific countries-for example, virtual reality fire safety training in Poland and a workplace health and safety module in Australia that received the LearnX 2023 Platinum Award.

In Hong Kong, we held a talk session in July 2023 on complications from COVID-19 infection and conducted a stretching class using a meditative sound bath in December 2023. In Taiwan, we held workshops on occupational health three times during the year, conducted workplace safety and health activities in line with the Taiwanese government's regulations, and obtained the Healthy Workplace Certification-Health Promotion Mark from the Health Promotion Administration (MOHW-HPA).

World Day for Safety and Health at Work

In support of the purpose of the International Labour Organization’s (ILO’s) World Day for Safety and Health at Work, we conduct awareness-raising activities on employee occupational safety and health at a global scale. For the 2023 World Day for Safety and Health at Work, we delivered a message to all employees about the importance of health and safety and a safe and healthy work environment.

In the Europe region, the Americas region, the Asia Pacific region, and at the Global Delivery Center, we conducted awareness campaigns on reporting hazards, accidents and incidents, and provided a variety of guidance for challenges in working from home and shift work, workplace adjustments, ensuring safety in abnormal weather conditions, occupational stress, safe lifting and working alone. To support employees on overseas business trips, we have also introduced risk assessments and provide guidance to ensure employee safety when overseas. In addition, we have in place occupational safety and health support tools for employees and conduct mock training in preparation for emergency situations (terrorist threats, pandemics, extreme weather events, fires, etc.).

Initiatives for Obtaining International Occupational Health and Safety Certifications, and External Evaluations

The international standard of ISO 45001 certification for occupational health and safety management (OH&S) has been obtained by some Group companies in Japan and by Group companies in the UK, Ireland, France, Spain, Australia, New Zealand, Germany, and Portugal, and in fiscal 2023, Group companies in India and Estonia newly gained certification. In addition, a team of occupational health and safety experts who are members of IOSH (Institution of Occupational Safety and Health) with training as ISO45001 lead auditors have been deployed in various overseas regions outside Japan to support a diverse workforce.

For external evaluations, we were recognized for our efforts to maintain and provide a healthy and safe working environment, and received the Work Environment Award from the Estonian Labour Inspectorate and the International Safety Award from the British Safety Council. We also participate in the Global Electronics Council’s Sustainability Technical Committee and the IOSH’s (Institution of Occupational Safety and Health’s) Business Leaders Forum.

Bureau Veritas ISO 45001 Certification (for 10 certified companies in regions outside Japan)

Bureau Veritas ISO 45001 Certification (for 10 certified companies in regions outside Japan) British Safety Council International Safety Award

British Safety Council International Safety Award ILO (International Labour Organization)

ILO (International Labour Organization) IOSH (Institution of Occupational Safety and Health)

IOSH (Institution of Occupational Safety and Health) LearnX 2023 Platinum Award

LearnX 2023 Platinum AwardGroup Companies with ISO 45001

FDK Corporation (Takasaki Plant, Tottori Plant, Kosai Plant, Washizu Plant) (Certification body: JACO)

Fujitsu Australia Limited

Fujitsu Services Ltd

Fujitsu Services GmbH

Fujitsu Technology Solutions GmbH

Fujitsu Technology Solutions SA

Fujitsu Technology Solutions SAS

Fujitsu Technology Solutions LDA

Fujitsu New Zealand Ltd

Fujitsu Consulting India Pvt Limited

Fujitsu Estonia AS

Occupational Accident Response and Workplace Management

In parallel with thorough prevention measures for workplace accidents, each region and country promptly responds when a workplace accident occurs.

When an employee in Japan is injured at work, a workflow is implemented to quickly and appropriately collect information about the workplace accident, such as when and where the accident occurred, with a strengthened response up through the Human Resources Unit. After confirming the contents of employee and workplace repots, the Human Resources Unit conducts interviews with the persons involved in the accident and the related parties to obtain further details as well as to take the necessary measures for injured persons to recover from the workplace accident. In addition, we are always available to employees for consultations about workplace accidents or general health and safety matters through our workplace management inquiry system.

In the Europe region, the Americas region and at the Global Delivery Center, our workplace accident reporting system (Ask Safety) is used for reporting and investigating workplace accidents and managing measures to prevent recurrences. We also regularly promote use of this system to our employees at the regional and national levels through various kinds of training, our intranet sites, and webinar sessions. In addition, in the Europe region and at the Global Delivery Center, we encourage employees to regularly review their work environment, with 49,000 improvements made in 2023. Under the management of OHS expert teams in each country, we ask for workplace adjustments when problems have been identified during individual assessments. We also have in place an international safety management system that supports adjustment procedures for the workplace environment.

Occupational Accident Occurrences (Fujitsu and Group Companies)

Japan*1

| 2020 | 2021 | 2022 | 2023 | |

|---|---|---|---|---|

| Frequency rate*2 | 0.11 | 0.04 | 0.03 | 0.09 |

| Severity rate*4 | 0.00 | 0.00 | 0.00 | 0.00 |

- *1Fujitsu Limited (reference period: January to December of each year)

- *2Calculated in accordance with the regulations of the Ministry of Health, Labour and Welfare in Japan: Frequency rate ([Number of new cases of fatal and non-fatal occupational injury during the reference period (*3) / Total number of hours worked by workers in the reference group during the reference period] x 1,000,000)

- *3Number of cases due to occupational accidents that resulted in one or more days of absence from work or the loss of a part of the body or its functions

- *4Calculated in accordance with the regulations of the Ministry of Health, Labour and Welfare in Japan: Severity rate ([Number of days lost due to new cases of fatal and non-fatal occupational injury during reference period / Total number of hours worked by workers in the reference group during the reference period] x 1,000)

International regions (January–December 2023)

| Europe Region | Global Delivery Center | Americas Region | Asia Pacific Region | East Asia | |

|---|---|---|---|---|---|

| Non-fatal occupational injury frequency rate*5 | 0.82 | 0.09 | 0.39 | 0.71 | 0.50 |

| Non-fatal occupational injury severity rate*6 | 24.72 | 1.70 | 5.49 | 55.04 | 0.50 |

- *5Calculated in accordance with the regulations of ILO: Non-fatal occupational injury frequency rate ([Number of new cases of non-fatal occupational injury during the reference period] / [Total number of hours worked by workers in the reference group during the reference period] x 1,000,000)

- *6Calculated in accordance with the regulations of ILO: Non-fatal occupational injury severity rate ([Number of days lost due to new cases of non-fatal occupational injury during the reference period] / [Total number of hours worked by workers in the reference group during the reference period] x 1,000,000)

Absentee rate*7

| Fiscal 2020 | Fiscal 2021 | Fiscal 2022 | Fiscal 2023 | Fiscal 2023 (target) | |

|---|---|---|---|---|---|

| Employee absentee rate*8 | 0.857% | 1.012% | 1.336% | 1.090% | 1.068% |

| Number of employees | 67,614 | 66,022 | 62,345 | 61,946 | - |

- *7Based on the number of full-time employees as of the end of the fiscal year (March 20) of Fujitsu Limited and Group companies in Japan (59 companies in FY2022, 56 companies in FY2023).

- *8Employee absentee rate (Absentee rate = [Number of absentee days*9 / Total days scheduled to be worked in the accounting period] x 100)

- *9Number of absentee days= Absence + Leave of absence (including absentee days and leave of absence due to illness and an accident, and absentee days due to an occupational accident)