-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals for FY2025

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Supply Chain

WHAT FUJITSU ASPIRES TO BE

In its supply chain, the Fujitsu Group will achieve responsible procurement that embraces diversity and gives full consideration to human rights, the environment and health & safety.

GOALS FOR FY2025

Prevention and reduction of human rights risks in the supply chain

- In addition to requesting compliance with the Procurement Guideline, promote the visualization and identification of issues with suppliers and establish a system that prevents problems from occurring

Promotion of GHG emissions reduction in the supply chain

- To promote GHG emissions reduction together with our suppliers, request major suppliers to set numerical targets in line with international standards

(The goal is for our major suppliers to set emissions reduction targets equivalent to SBT WB2℃)

Ensuring diversity in the supply chain

- Based on the social demands of each region and country, set indicators for diversity and engage in activities

- Set support for "empowerment of women" as the main activity in the supply chain in Japan and establish a system to measure the efforts of suppliers

Policy

The Fujitsu Group holds “Co-existence with Suppliers”, “Fair and Proper Evaluation and Selection of Suppliers” and “Promotion of Sustainability in Procurement Activities” as the tenets of its Corporate Social Responsibility (CSR) procurement policy, and conducts its global procurement activities accordingly.

In 2005, we developed the "CSR Procurement Guidelines” for sustainable procurement and requested our suppliers in Japan and overseas to comply appropriately. In 2018, we adopted the RBA (*1) Code of Conduct as our "Fujitsu Group CSR Procurement Guidelines." We revised the guidelines in 2023, changed the name to “Fujitsu Group Sustainable Procurement Policy”, and are now in the process of requiring our main suppliers to provide their written agreement to the Policy.

- (*1)[PRESS RELEASE] Fujitsu Joins EICC, a Global Corporate Social Responsibility Coalition

(which was rebranded to become the Responsible Business Alliance (RBA) in October 2017)

Sustainable Procurement Activities & Periodic Reviews

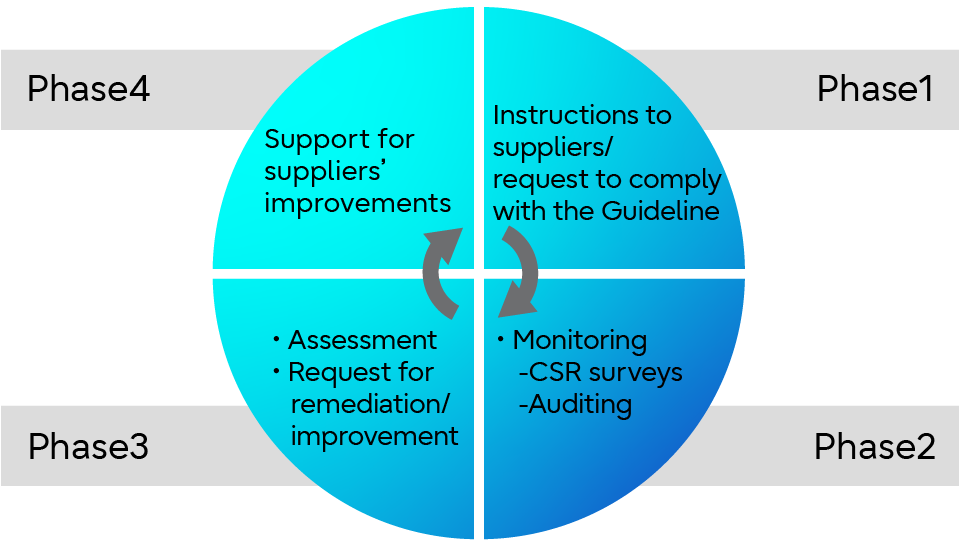

Processes for Promoting and Improving Sustainable Procurement

Processes for Promoting and Improving Sustainable Procurement

Under the group-wide policy, the relevant divisions in the Fujitsu Group collaborate regarding sustainability activities. In the area of procurement, the Global Supply Chain Unit works with the relevant divisions in promoting sustainable activities by suppliers. The sustainability activities are targeted at our major suppliers, that is, the largest suppliers by procurement value and those who have ongoing dealings with Fujitsu.

We initially use the Sustainable Procurement Policy to clarify the compliance items and then require our suppliers to undertake sustainability activities. To confirm that these activities are being fully implemented by suppliers, we ask them to respond to a CSR survey, plus various other surveys on topics such as green procurement, information security and Business Continuity Management (BCM).

The survey responses are analyzed and the results are returned to the suppliers as feedback. Where a supplier fails to meet Fujitsu’s standards, we require them to undertake improvements. Where there is a particular need to check whether sustainability activities are being fully implemented by a supplier, a CSR audit is conducted. Such suppliers are required to submit a remediation plan for any matters identified by the audit and Fujitsu works with the suppliers to make the necessary improvements. Fujitsu is continually enhancing its processes and promoting sustainable procurement with the goal that ultimately sustainability activities will be properly undertaken by suppliers and will become firmly entrenched.

Imprimenting Activities and Participation in Industry-standard Initiatives (RBA Membership)

The Fujitsu Group is a member of the Responsible Business Alliance (RBA), a global CSR alliance. As such, we abide by the RBA’s Code of Conduct and engage in sustainable procurement with our suppliers and throughout our supply chain.

The RBA receives regular input from stakeholders to inform the ongoing development and implementation of the Code of Conduct.

Many companies in the Fujitsu Group supply chain are currently members of the RBA. We have incorporated the RBA Code of Conduct, which reflects the opinions of workers at those companies, into the Fujitsu Group Sustainable Procurement Policy. As such, we expect the suppliers with whom we do materials, parts, and hardware products business, to comply with the Policy.

The Fujitsu Group also takes an active role in the programs and initiatives of organizations such as the Japan Electronics and Information Technology Industries Association (JEITA) and works to implement sustainable procurement in the industry.

Addressing High-Risk Minerals

Structure for Responsible Minerals Procurement

Structure for Responsible Minerals Procurement

The policy of the Fujitsu Group is to exclude from its products, components and supply chain any minerals that give rise to conflicts (“conflict minerals”), or minerals that are at high risk of being associated with forced labuor or human rights violations. (The Fujitsu Group identifies tantalum, tin, gold, tungsten and cobalt as high-risk minerals.) Fujitsu has also established a structure to ensure the transparency of procurement activities in the supply chain and the responsible procurement of minerals. This structure includes the relevant internal divisions and operates under the jurisdiction of the Sustainability Management Committee (chaired by Fujitsu’s CEO).

Surveys on High-Risk Minerals

As part of its due diligence, the Fujitsu Group conducts high-risk minerals surveys with reference to the “OECD Due Diligence Guidance for Responsible Supply Chains of Minerals from Conflict-Affected and High-Risk Areas”. These surveys use the Conflict Minerals Reporting Template (CMRT) and Extended Minerals Reporting Template (EMRT) developed by the Responsible Minerals Initiative (RMI).

Reminders are sent to those suppliers who failed to respond to our survey by the due date. If survey responses reveal insufficient answers, suppliers are asked to resubmit their responses. Where customers indicate that a smelter is considered to be “risky”, we ask suppliers using that smelter to re-examine the nature of their dealings with the smelter.

While there have been no confirmed reports yet of smelters having any involvement with armed groups, we will continue to conduct programs aimed at identifying smelters and further increasing transparency in our supply chain.

Promoting Green Procurement

The Fujitsu Group has set out its basic approach to the environmentally sound procurement of components, materials and products in the Fujitsu Group Green Procurement Direction, and we are working with our suppliers to promote green procurement activities. One target for such activities is the reduction of CO2 emissions, and the Fujitsu Group is requesting that its suppliers, and their suppliers in turn, set targets and promote activities to reduce their CO2 emissions. In addition, we are asking our suppliers to conduct water risk assessments as a first step toward water resource conservation. We will continue to promote activities that reduce environmental impacts throughout our supply chain.

Promoting the Setting of Greenhouse Gas Emissions Reduction Targets in the Supply Chain

With the intention of accelerating the journey to carbon neutrality, the Fujitsu Group has set FY2030 as its new goal to reduce its carbon emissions to zero, 20 years ahead of the previous schedule. The Fujitsu Group has achieved SBTi net zero certification as a result. Moreover, the Group is working to achieve net zero emissions across the entire value chain (Scope 3), including the supply chain, by FY2040.

To work together with our suppliers on reducing greenhouse gas (GHG) emissions in the supply chain, we hold briefings for our major suppliers, encouraging them to set reduction targets in line with international standards and implement reduction activities.

Promoting Diversity in the Supply Chain

The Fujitsu Group is committed to ensuring diversity throughout the supply chain. We believe that an environment in which diverse human resources are afforded equal opportunities and can leverage each other’s values and abilities is essential to fostering innovation and, ultimately, to building and developing a robust, sustainable supply chain.

Given that societal issues and challenges differ depending on the country and location, our supplier diversity initiatives are based on policies developed and implemented according to the characteristics of each country/location. In Japan, for example, since women's empowerment figures prominently on the social agenda, we are promoting activities under the theme of supporting women's empowerment in the supply chain. Specifically, as a first step toward visualizing the status of our initiatives and to foster awareness, we are asking our major suppliers to register information on the status of women's empowerment at their companies in the “Database of Companies Promoting Women’s Participation and Advancement in the Workplace” established by the Ministry of Health, Labour and Welfare.

Promoting Information Security Measures

Based on the “Cybersecurity Management Guidelines” issued in December 2015 by Japan's Ministry of Economy, Trade and Industry (METI) and the Information-technology Promotion Agency (IPA), the Fujitsu Group, along with its suppliers, has adopted the goal of “eliminating information security incidents”, and is continually implementing measures to prevent such incidents or recurrences. These measures include education, raising awareness, auditing and sharing information.

In recent years, there has been a significant increase in the commercial use of external services such as cloud computing and social media. There has also been a rapid increase in opportunities for the use of smart devices such as smartphones and tablet PCs. Regarding the risk of information leaks, it is necessary to prevent not only incorrectly addressed emails being sent by mistake and the theft or loss of PCs and smart devices, but also new kinds of risks such as in-house crimes and cyber terrorism. In this context, when the Fujitsu Group consigns work to suppliers, including those outside Japan, it promotes education and awareness by requiring the same standards of information security management and handling of personal information as it applies to its own operations. If any serious problem regarding information security is discovered at a supplier, or if the supplier fails to immediately implement corrective measures and no improvement is observed, Fujitsu will take steps such as reviewing its business relationship with the supplier.

Enhancing Supply Chain BCM

The Fujitsu Group sees the enhancement of Business Continuity Management (BCM) throughout its supply chain as essential to ensuring a stable supply of products and services in the event of major disasters or other unexpected contingencies. Accordingly, since FY2007 we have provided our suppliers with ongoing support to improve their BCM capabilities.

Fujitsu conducts an annual questionnaire-based survey of its suppliers on how they address BCM. This survey also covers some group companies that conduct their own procurement. We analyze the responses to the survey and then provide feedback to the suppliers and group companies. Since FY2014, we have been using a standard survey form developed by JEITA’s Materials Committee.

Fujitsu also conducts annual surveys of major solutions-related suppliers, analyzing the responses and providing feedback.

Communication with Suppliers

Feedback of Assessment Results in the Suppliers' Performance Review (SPR) System

Under the SPR (*2) System, the Fujitsu Group targets primarily its major suppliers and provides direct feedback on the assessment results. Suppliers whose efforts do not meet Fujitsu’s standards are asked to make improvements. Fujitsu also carries out assessments of solutions-related suppliers and provides the results of those assessments as feedback to the major suppliers.

- (*2)Suppliers’ Performance Review: A program developed by Fujitsu that assesses the performance of procured goods and the basic profile of enterprises in terms of quality, technology, price, supply and CSR.

Strengthening Procurement Compliance

Education by Procurement Divisions

Fujitsu Group conducts training programs for our procurement staff to disseminate awareness of sustainability and ensure that procurement is socially responsible. In addition to sustainable procurement and green procurement, training aimed at increasing awareness among procurement staff is also offered in the areas of risk management (BCM activities) and compliance with legislation such as the Act Against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors and the Act on Securing the Proper Operation of Worker Dispatching Businesses and Protecting Dispatched Workers.

Complying with the Act Against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors

The entire Fujitsu Group makes every effort to maintain legal compliance in accordance with the Fujitsu Way Code of Conduct and Global Business Standards (GBS). We also educate the entire Fujitsu Group and our suppliers on the Act Against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors.

In FY2023, we did not violate the Act Against Delay in Payment of Subcontract Proceeds, etc. to Subcontractors.

Announcement of "Declaration of Partnership Building"

Fujitsu has developed and announced its “Declaration of Partnership Building” in order to build new partnerships by promoting cooperation and coexistence with suppliers and value-creating businesses.

The Declaration of Partnership Building is an initiative introduced by the “Council for Promoting Partnership Building for the Future”, whose members include the Chairman of Japan Business Federation, the President of Chamber of Commerce and Industry, the President of the Japanese Trade Union Confederation, and relevant ministers (Minister of Economy, Trade and Industry, Minister of State for Special Missions (Minister of State for Economic and Fiscal Policy), Minister of Health, Labour and Welfare, Minister of Agriculture, Forestry and Fisheries, and Minister of Land, Infrastructure, Transport and Tourism).

Details of the Declaration of Partnership Building and Fujitsu's declaration are available on the portal site operated by the National Association of Small and Medium Enterprise Promotion Organizations.

Supplier Compliance Line

The Fujitsu Group uses the Supplier Compliance Line as a channel to receive reports from suppliers regarding any actions that are potential or actual instances of non-compliance in our purchasing activities. Channels have been set up both internally and externally through which we can verify and investigate the facts of each report and respond quickly.

Fujitsu’s internal reporting standards prohibit any adverse treatment of its own staff making such reports or of staff from suppliers making the reports.

Our agreements with suppliers also include explicit provisions on the elimination of anti-social forces and other such groups with the aim of preventing harmful actions by such anti-social forces (and avoiding any encouragement of their activities). The Fujitsu Group, including its suppliers, will have no relationship whatsoever with anti-social forces.

FY2023 Performance

Obtaining Agreement to the Procurement Policy

- We announced our new procurement guidelines entitled “Fujitsu Group Sustainable Procurement Policy” and obtained written agreement from 220 companies.

CSR Surveys

- CSR surveys of major suppliers in Japan and overseas: 441 companies

High-Risk Mineral Survey Results

- Fujitsu received responses from 89.2% of the suppliers surveyed.

- Smelters operated by 542 companies were checked, of which 274 were compliant with the RMI-certified Responsible Minerals Assurance Process (RMAP).

Implementing GHG Emissions Reductions in the Supply Chain

- We completed the setting of emissions reduction targets for 40% of our suppliers based on the procurement value for FY2022.

Ensuring Diversity in the Supply Chain

- We held briefing sessions on the promotion of women's empowerment for suppliers with head offices in Japan, which accounted for 68% of procurement value in FY2022, and requested them to register their targets in the “Database of Companies Promoting Women's Participation and Advancement in the Workplace” (271 companies participated; 262 companies have already registered).

- We also achieved procurement KPIs in overseas subsidiaries from companies with a diverse set of attributes (eg, SMEs, women-owned/led businesses, minority-owned businesses)

Promoting Information Security Measures

- Surveys on the state of information security measures (Jan.-Mar. 2024): 2,219 companies

Enhancing Supply Chain BCM

Products:

- Surveys conducted (Jul-Oct 2023): Approximately 600 companies, 1,400 locations

- Feedback provided (Dec 2023): Approximately 600 companies, 1,400 locations

Solutions:

- Assessment feedback provided: Approximately 270 companies

Communication with Suppliers

Products:

- Feedback provided (Dec 2023): Approximately 600 companies, 1,400 locations

Solutions:

- Held quarterly partnership meetings to share business status and associated issues. 165 companies participated over the year.