-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Case Studies

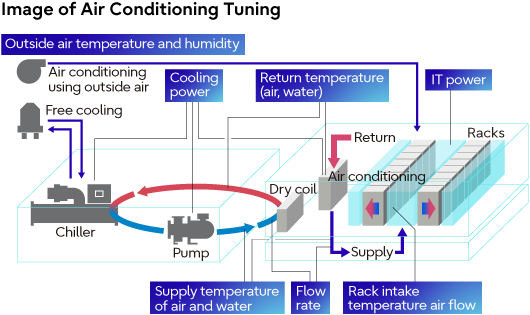

Reducing Air Conditioning Power With a Focus on Improved Operation

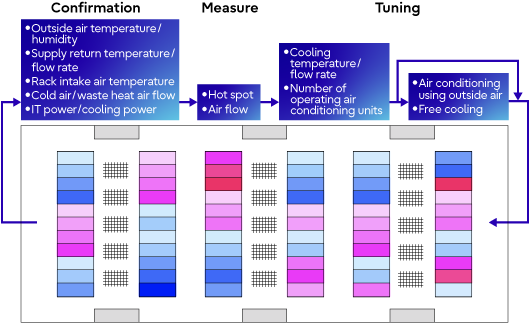

Due to the impact of the spread of COVID-19, improvement activities could not be started as planned at some data centers. However, we are implementing overall air conditioning tuning according to IT power consumption (heat generation). We expanded the target floors through measures such as lessening the air conditioning temperature and cold water temperature, and adjusting the number of cooling equipment in operation. Furthermore, at data centers with air conditioning using outside air or free cooling, the outside air temperature was relatively low compared to the previous fiscal year, so we started operating them early in the middle of the plan in an effort to reduce power consumption for air conditioning. We are also expanding the target floors for AI control of air conditioning, which started operation at one domestic data center from FY 2019, and reduced the overall energy used for air conditioning by 15% to 20%. We plan to continue the rollout to include other data centers.

[September, 2022]

Promoting Improvements through Better Information Sharing with Overseas Data Centers

In an effort to coordinate our PUE improvement activities with overseas data centers and further enhance our activities, we conduct regular meetings remotely in order to share and communicate information such as the progress of improvement and know-how on improvement measures gained at each data center. We are planning to share related information on internal portal sites and to use the sophistication of data to visualize the progress status and improvement points. These measures will enable improvement activities to progress more smoothly in the future.

[September, 2022]

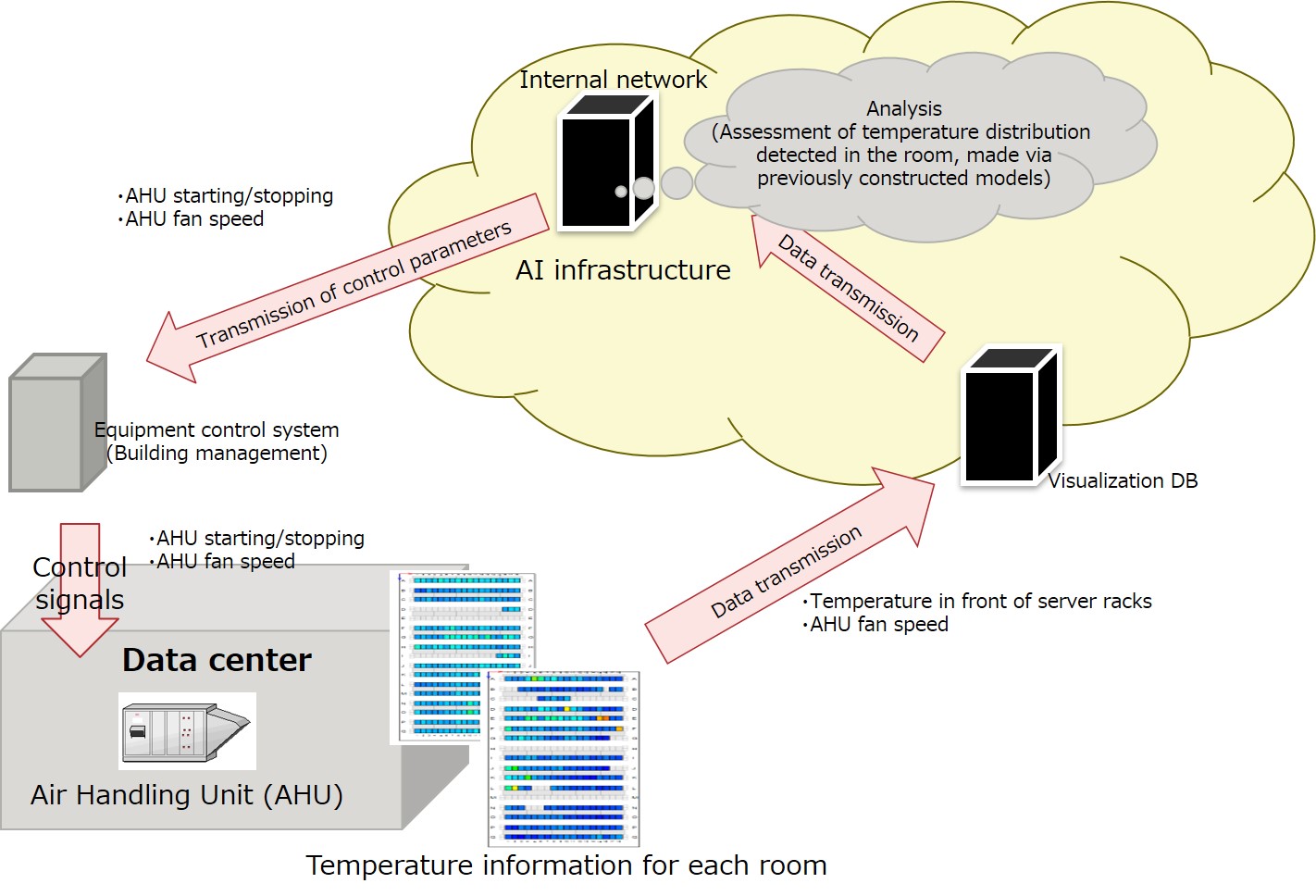

Making Energy Use for Cooling More Efficient Through AI-Controlled Air Conditioning

We began full-scale operations in the first half of FY 2019 at one major data center in Japan, and have covered approximately 60% of all server rooms by AI controls. We reduced the overall energy used for air conditioning by 15-20%, and we plan to continue the rollout to include other data centers in FY 2021.

[September, 2021]