-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Reduction of CO2 Emissions by Reducing Power Consumption When Using Products

Our Approach

As ICT grows more and more common, we expect there to be an increase in energy demand in proportion to the higher performance and higher-density integration of ICT products. Various countries and regions are also expanding their energy-related regulations for ICT products, and energy efficiency is taking on increasing social importance as a factor in energy label conformance and green procurement requirements.

Here at the Fujitsu Group, we believe that we should work to improve the energy performance of our products during their use, in order to reduce GHG emissions. As such, we will actively implement energy-saving technologies and continue working to further improve the energy efficiency of products. Through these efforts, we will work to promote the development of products that contribute to reduced power consumption when in use.

FY2023 Performance

| Targets under the Fujitsu Group Environmental Action Plan (Stage XI) | FY2023 result |

|---|---|

| Reduce CO2 emissions due to product power consumption by 7.5% or more in comparison to FY2020. | Reduced by 34.2% |

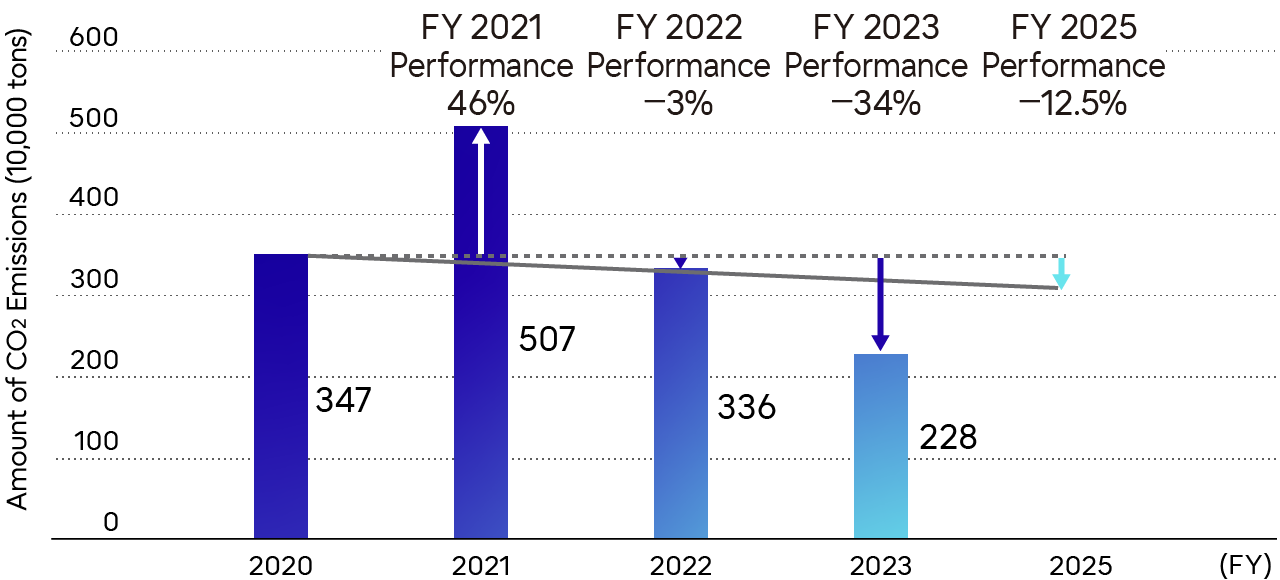

Change in CO2 Emissions Due to Product Power Consumption

Change in CO2 Emissions Due to Product Power Consumption

Fujitsu Group Environmental Action Plan (Stage XI) Initiatives

Aiming for net-zero emissions for the entire value chain, the Fujitsu Group Environmental Action Plan (Stage XI) has set a target of reducing emissions in FY 2025 by 12.5% or more in comparison to FY 2020. To achieve this target, each unit has been working to improve energy efficiency, etc. of products in the FY2023–FY2025 pipeline. Specifically, we are actively pushing the use of low-power components, aggregating functions to reduce terminal numbers, using high-efficiency power supplies, optimizing power-management controls, reducing the number of components, and implementing eco-friendly devices.

Attained a 34.2% Reduction in CO2 Emissions in Comparison to FY2020

In FY2023, as a result of applying and expanding energy-saving technologies in our servers, storage, PCs, and network devices, we were able to attain a 34.2% reduction in CO2 emissions in comparison to FY2020.

Working Toward Our Targets

In order to achieve net-zero GHS emissions across the entire value chain, each unit will work to further develop products with improved energy efficiency. We will also implement advanced energy-saving technologies and expand their application to our products, as part of our cross-Group policy to improve energy efficiency.

Looking toward the future, we aim to push the development of advanced eco-friendly devices, which will contribute to revolutionary improvements in energy efficiency, and aim for the products to be applied at an early stage.

Initiatives in FY2023

CELSIUS W5012-Combined speed, power, stability and energy savings

The CELSIUS W5012 PC is a fully equipped PC workstation with the latest technology. PC workstations are designed to perform processing-intensive tasks, and our CELSIUS series provides this functionality.

The CELSIUS W5012, which came to market in FY2023, features Windows 11 Pro, a 13th generation Intel® Core™ processor and DDR5 memory, and is suitable for CAD, architectural and structural analysis, healthcare, and 2D and 3D video production.

In terms of eco-friendliness, the use of low-power components has enabled a 44% reduction in power consumption during use compared with previous models. CELSIUS W5012 also achieved an AAA rating in energy consumption efficiency (FY2022 standard) based on Japan’s Energy Conservation Act.

With full deployment of the latest technologies with energy savings in the CELSIUS W5012, Fujitsu will continue to strive to realizing a society that is both environment- and people-friendly.