-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Case Studies

- FACT-X functions as a new ATM that conserves energy

- ARROWS Tab Q7312 balancing improved performance of the same sized laptop computer and resource efficiency

- Featuring state-of-the-art optical transport technology, the 1FINITY T700 has improved resource efficiency and reduced energy consumption

- Development of FRAM That Makes Maximum Memory Capacity and Industry-Leading Level of Energy Efficiency

- The LIFEBOOK U7511/G Laptop, Which Strikes a Balance between Convenience for Mobile Workers and Resource Efficiency

FACT-X functions as a new ATM that conserves energy

FACT-X

FACT-X

FACT-X is a next-generation ATM for a cashless era. It works as a bank teller in addition to serving as a full-service ATM. Developed under the concept of “accessible to all,” the ATM has many thoughtful features with all users in mind, including simple operation and accessibility, security design, and ease of use for those unfamiliar with ATMs or in a wheelchair. We also provide operational support services to the companies that operate ATMs, including remote functions and remote maintenance services. In addition, we will continue to provide functions that meet customer needs, including features to reduce teller operations.

In terms of environmental considerations, we have revised the function and parts of the new model to include complete transition from paper journals to electronic journals and adoption of SSD, in addition to offering the Super Eco Mode which turns the power off when no users are present in existing models. This update reduced power consumption by 15% when in use compared to conventional models*. (*Compared to FACT-V X200)We strive to help customers achieve sustainability and transformation through enhanced customer services and provision of channel reform through FACT-X as a new contact point.

[September 2023]

ARROWS Tab Q7312 balancing improved performance of the same sized laptop computer and resource efficiency

ARROWS Tab Q7312/KB

ARROWS Tab Q7312/KB

ARROWS Tab Q7312 is a high-end tablet device featuring a large screen ideal for a wide range of uses. It offers advanced functions and scalability for business and comes equipped with advanced security features including a TPM 2.0 security chip and (optional) fingerprint scanner. In addition to high-end features, the tablet only weighs about 1.2kg even when including the specialized slim keyboard.

In terms of the environment, ARROWS Tab Q7312 improves resource efficiency by 2.1% with the use of components made of recycled plastics. It is also Energy Star certified because of its reduced consumption of electricity.

By offering the ARROWS Tab Q7312 tablet featuring high-end specifications, scalability and improved resource efficiency, Fujitsu will contribute to a society that is equally considerate of both the environment and people.

[September 2023]

Featuring state-of-the-art optical transport technology, the 1FINITY T700 has improved resource efficiency and reduced energy consumption

1FINITY T700

1FINITY T700

The 1FINITY series are optical transport systems that support telecommunications carrier systems. Optical transport equipment transmits information and it sends data. The 1FINITY series separates the functionality of conventional optical transport equipment to enable capital investment suitable for the scale of the network, continuous network evolution, minimization of running costs, and flexible operation.

We have developed the 1FINITY T700 as part of the 1FINITY series. The 1FINITY T700 Transport Blade is capable of long-distance transport at 400 Gbps*. The 1FINITY T700 is equipped with state-of-the-art optical transport technology and it allows flexible optical path (line) management.

From an environmental perspective, the 1FINITY T700 reduces the environmental burden in terms of both resource and energy conservation. The components of the 1FINITY T700 are smaller, fewer in number, consolidated, and modular, improving resource efficiency with respect to performance by 40.0% compared to previous models. Moreover, the use of industry-leading reduced power consumption technology has reduced power consumption with respect to transport performance by 45% compared to previous models.

The 1FINITY T700 features state-of-the-art optical transport technology and improved resource efficiency. Through this system, we will help to create an affluent society.

Gbps*: A unit of data transport speed that indicates how many gigabits of data can be sent per second

[September 2022]

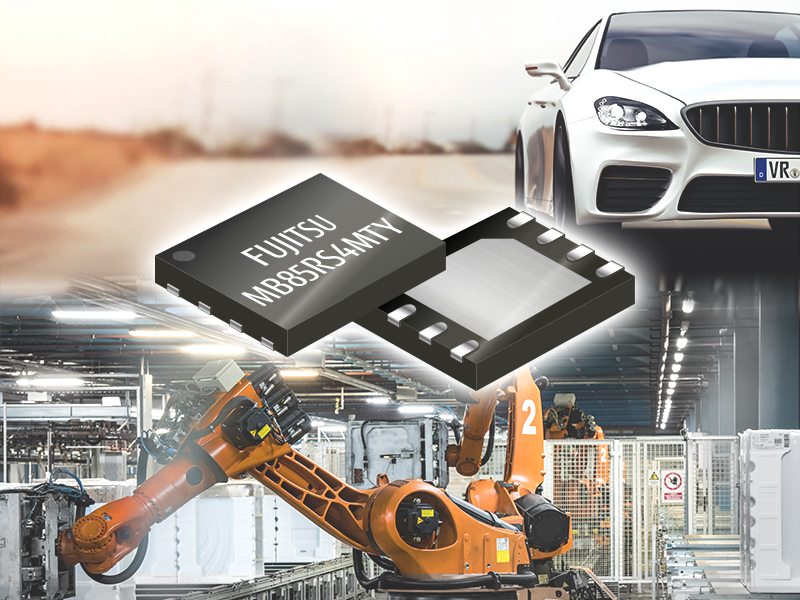

Development of FRAM That Makes Maximum Memory Capacity and Industry-Leading Level of Energy Efficiency

MB85RS4MTY

MB85RS4MTY

FRAM(Ferroelectric Random Access Memory) is non-volatile memory which excels in terms of its guaranteed rewrite count, writing speed, and power consumption. In recent years, FRAM has also been used in wearable devices, industrial robots, and drones.

In addition to having the largest memory capacity of any FRAM product guaranteed to operate at 125°C, the 4 Mbit FRAM MB85RS4MTY we developed is also guaranteed to have 10 trillion data write cycles. It is suitable for in-vehicle applications, such as advanced driver assistance systems (ADAS), and for use in industrial robots.

From an environmental standpoint, by adopting commands that shift integrated circuits into a low power consumption mode called “deep power down mode,” as well as design techniques that take energy efficiency into account, we have achieved a maximum operating current of up to 4 mA (at 50 MHz operation), even in high-temperature environments of 125°C, and a power-down current of up to 30 µA, for an industry-leading level of energy efficiency.

Installing MB85RS4MTY will lead to reduced systemwide power consumption.

[September 2021]

The LIFEBOOK U7511/G Laptop, Which Strikes a Balance between Convenience for Mobile Workers and Resource Efficiency

LIFEBOOK U7511/G

LIFEBOOK U7511/G

The LIFEBOOK U7511/G is a laptop aimed at mobile workers. Weighing in at a light 1.32 kg*, and its 15.6-inch liquid crystal display is easy to work with. This makes it possible for the laptop to have the lightness needed by mobile workers, while also improving work productivity. Furthermore, to go along with the implementation of a BIOS tampering check and self-recovery functions, a fingerprint sensor, palm vein sensor, and smart card slot can be installed to provide optimal security measures in response to the usage environment and the kind of work. In terms of environmental friendliness, the installation of an Intel® Core™ i5 processor (Tiger Lake), a narrow-frame design that reduces the size of the case, and the use of recycled plastic for some parts of the case have achieved resource efficiency of 26.1%, while improving the laptop’s functions in comparison to conventional models. Additionally, by designing the model with energy conservation in mind, we have achieved compliance with the International Energy Star Program, as well as "AA" energy consumption efficiency (FY2022 standard) based on the Energy Conservation Act.

In addition to this, ScanSnap iX1600/1400, the personal document scanner targeted at individuals, has adopted recycled plastic materials made from recovered PET bottles for product parts. Thus, we have been contributing to lessening our environmental impact also in terms of parts.

*Product weight is the weight (average value) with a standard battery installed.

[September 2021]