-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- GRB(Global Responsible Business)Goals for FY2025

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Limiting the Amount of Waste Generated

Our Approach

The Fujitsu Group considers wastes as valuable resources and has continued to work toward recovering resources from its waste or using the waste as a source of energy. In Japan, our volume of final waste disposal has been decreasing every year. However, the environment surrounding waste disposal remains challenging as building new disposal sites is difficult and the existing ones have limited lifespans.

We are actively working to install new equipment and reuse waste with the objective to reduce the amounts of waste acid, waste alkali and sludge generated in the production of semiconductors and printed circuit boards. These efforts are in line with Japan's Fundamental Law for Establishing a Sound Material-Cycle Society to (1) reduce waste generated, (2) reuse it, (3) recycle it and (4) recover heat from it.

We have also established the company-wide Standards for Consignment of Waste Disposal to properly dispose of waste, based on the Waste Management and Public Cleansing Law.

On-site Audits for Outsourcing Contractors

We conclude contracts with waste processing companies. These contracts are common for the whole Fujitsu Group. We conduct on-site audits of the waste processing companies with which we have contracts to periodically confirm that waste is being appropriately processed. If multiple business sites have contracts with the same processing company, then a representative business site conducts on-site audits based on the representative auditing regulations. In other cases, each business site individually conducts audits to confirm that waste processing is appropriate.

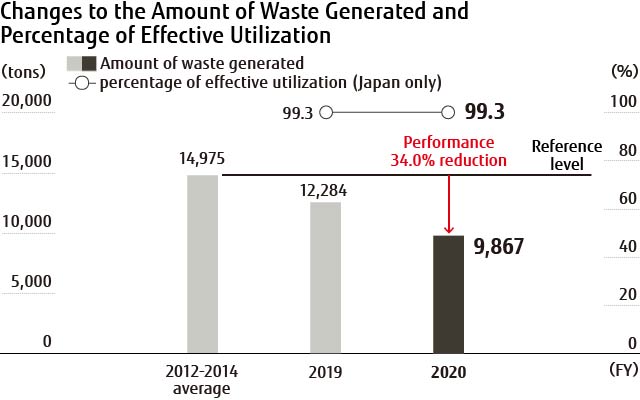

FY 2020 Performance

| Targets under the Fujitsu Group Environmental Action Plan (Stage IX) | Last fiscal year (FY2020 result) |

|---|---|

| Reduce the amount of waste generated by 5% or more of the average amount generated from FY 2012 to FY 2014 (Target 14,226 t/year or less)(*1) | 34% reduction |

- (*1)Target organizations: Fujitsu and Fujitsu Group manufacturing sites

Promoting Measures to Reduce Waste Generation and Plastic Waste

Starting in January 2020, Fujitsu I-Network Systems Ltd. has taken parts reels, which had previously been waste material, and converted them into valuable resources. By doing so, it was able to reduce the amount of waste it generated by 7.6 tons in FY 2020. In addition, as a new measure to reduce the amount of waste plastic we generate at our Oyama Plant, starting in FY 2020, we began collaborating with external reuse companies to partially reuse the IC trays that are used when procured parts are delivered, and were able to reduce the amount generated by 10.7 tons. As a result of these initiatives, we could achieve our target by reducing the amount of waste we generate to 9,867 tons (basic unit per sales amount: 0.27 tons/100 million yen).

Breakdown of Waste Generated, Effective Use, and Final Disposal (in tons)

| Type of Waste | Waste Generated | Effective Use | Final Disposal |

|---|---|---|---|

| Sludge | 1,275 | 1,185 | 90 |

| Waste oil | 1,021 | 1,010 | 12 |

| Waste acid | 1,055 | 1,052 | 3 |

| Waste alkali | 1,653 | 1,576 | 77 |

| Waste plastic | 2,177 | 2,130 | 47 |

| Waste wood | 463 | 429 | 35 |

| Waste metal | 628 | 628 | 0 |

| Glass/ceramic waste | 228 | 225 | 3 |

| Other(*2) | 1,367 | 1,234 | 133 |

| Total | 9,867 | 9,467 | 399 |

- (*2)Other includes general waste, wastepaper, septic tank sludge, cinders, rubble, textile waste, animal and plant residue, and infectious waste.