-

Sustainability at Fujitsu Group

- Sustainability Management in the Fujitsu Group

- GRB(Global Responsible Business)Goals for FY2025

- GRB(Global Responsible Business)Goals and Achievments for FY2022

- Fujitsu's accessibility

- Stakeholder Engagement

- United Nations Global Compact

- SDG-related Activities in Fujitsu

- External Recognition and Awards

-

Global Responsible Business

- Environment

-

- Environmental Management

- The Fujitsu Group Environmental Vision on Climate Change

- Living in Harmony with Nature (Conservation of Biodiversity)

- Environmental Action Plan

- Environmental Data

- Environmental Communication

- Environmental Social Activities

- Disposal and Recycling of ICT products

- Environmental Considerations in ICT Products

- Governance

-

Data and Documents

- Fujitsu Group Sustainability Data Book 2024

- Social, Governance and Environmental data

- Independent Assurance Report

- GRI Standards / United Nations Global Compact (UNGC) principles Comparison Table

- SASB Standards Comparison Table

- Sustainability Information Disclosure Framework

- Link to regions responsible business reports

- Contact

- Sitemap

Quality Initiatives

Our Policy

The Fujitsu Group has the important responsibility of supporting businesses and lifestyles of our diverse customer base, beyond developing better society, through providing a wide range of products and services. In order to contribute to the creation of a trusted society, the entire Fujitsu Group utilizes technology to ensure stable operation and improve the quality of our customers' systems.

Fujitsu Global Quality Policy / Quality Standards System

Fujitsu Global Quality Policy / Quality Standards System

To that end, the Fujitsu Group has established the Fujitsu Global Quality Policy to put the Fujitsu Way's cherished value of trust into practice. This policy recognizes quality as a foundational part of our business and shows how we will continue to provide safe and secure products/services worldwide.

In line with the Fujitsu Way and the Fujitsu Global Quality Policy, we have established Quality Policy (Standard Policy for Quality Management) and Global Quality Rules under the Fujitsu Group Global Policy which outlines the rules that the entire group adheres to. Under the Fujitsu Group Global Policy, we have established regulations and standards tailored to the characteristics of the countries where we do business, our products/services, customer requests, and applicable laws and restrictions.

For example, in Japan, we have established the Fujitsu Group Quality Charter and five Quality Assurance Regulations (including Shipment, Registration, Release, and Safety Promotion Regulations).

All of our measures, from planning to design to verification, production, sales, and even follow-up support, are based on this charter and these regulations. This ensures that we continue to provide products/services that stay one step ahead of our customers and any changes in their business landscapes.

Implementation Policy for the Safety of Our Products and Services

The Fujitsu Group recognizes its social responsibility to contribute to building a safe and secure society. The Fujitsu Group always considers and endeavors to improve the safety of products and services in every aspect of the group's business activities.

- Observation of laws and regulations

We observe laws and regulations concerning product and service safety. - Efforts to secure safety

We try to ensure that products and services are safe in a variety of use situations and take measures as necessary to secure the safety of the products and services. In addition to legally specified safety standards, we develop and observe voluntary safety standards in our endeavors to improve products and services continuously. - Prevention of incidents caused by improper use, etc.

For the safe use of products and services by customers, we properly display notices and warnings in handbooks or on the body of the products in order to prevent incidents caused by improper use or carelessness. - Collection of incident information, etc.

We actively collect safety-related information from customers, including information on product and service incidents and what might lead to such an incident. - Handling of incidents

We immediately check the facts of any occurring incident related to a product or service, investigate the cause, and handle it properly. If the product or service has a safety problem, we provide that information to customers and take proper measures, such as product recall, service recovery, and prevention of further damage and other damage from occurring. We quickly report the occurrence of major product incidents to the proper authorities in accordance with laws.

Our Quality Management Structure

Our Quality Management Structure

Our Quality Management Structure

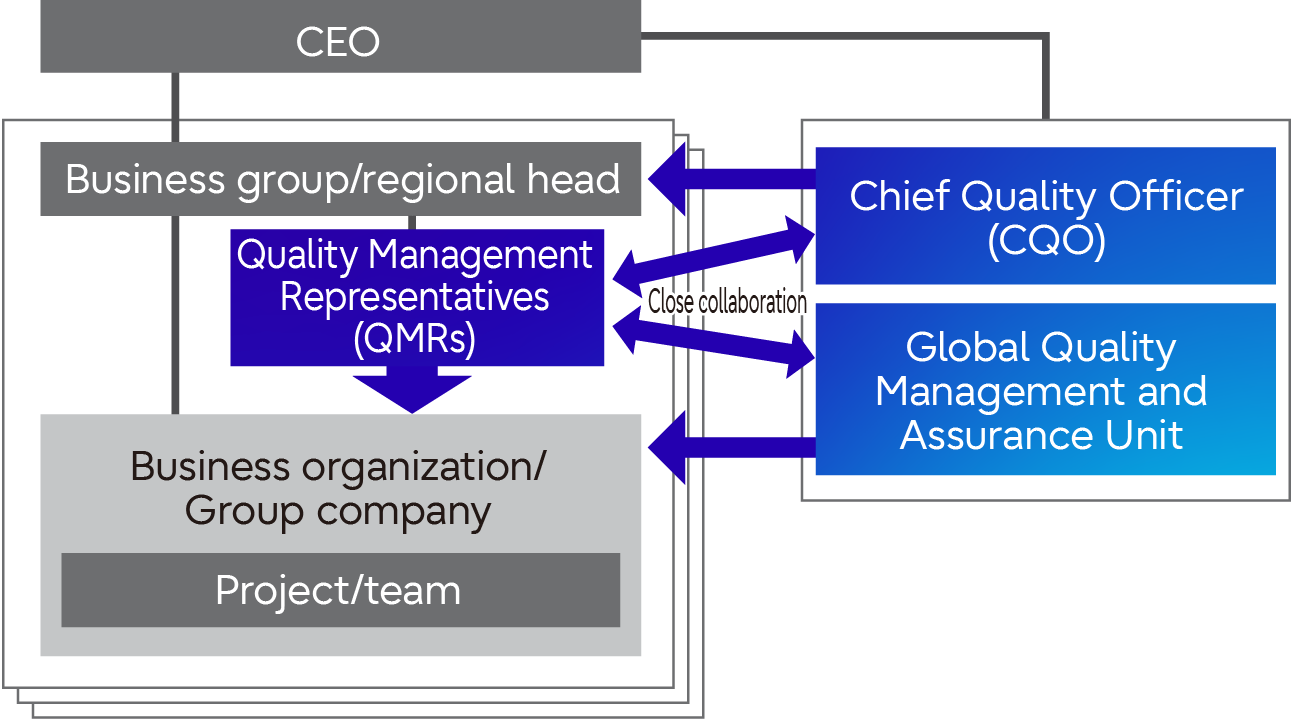

The Fujitsu Group appointed a Chief Quality Officer (CQO) in June 2023 in an effort to enhance the quality of our products/services across the entire Group.

Furthermore, Fujitsu established Quality Management Representatives (QMRs) in each business group and Group company to govern Groupwide quality management under the leadership of the CQO. Following the decision and direction of the CQO, the Global Quality Management & Assurance Unit formulates common policies, standardization, and quality improvement measures as the headquarters of quality. By deploying these common measures through QMRs with close collaboration, we strive toward more field-oriented implementation and application, and perform quality management in an effort to provide products/services with consistent and optimal quality for our customers.

Our Quality Support Framework

Our Quality Support Framework

Our Quality Support Framework

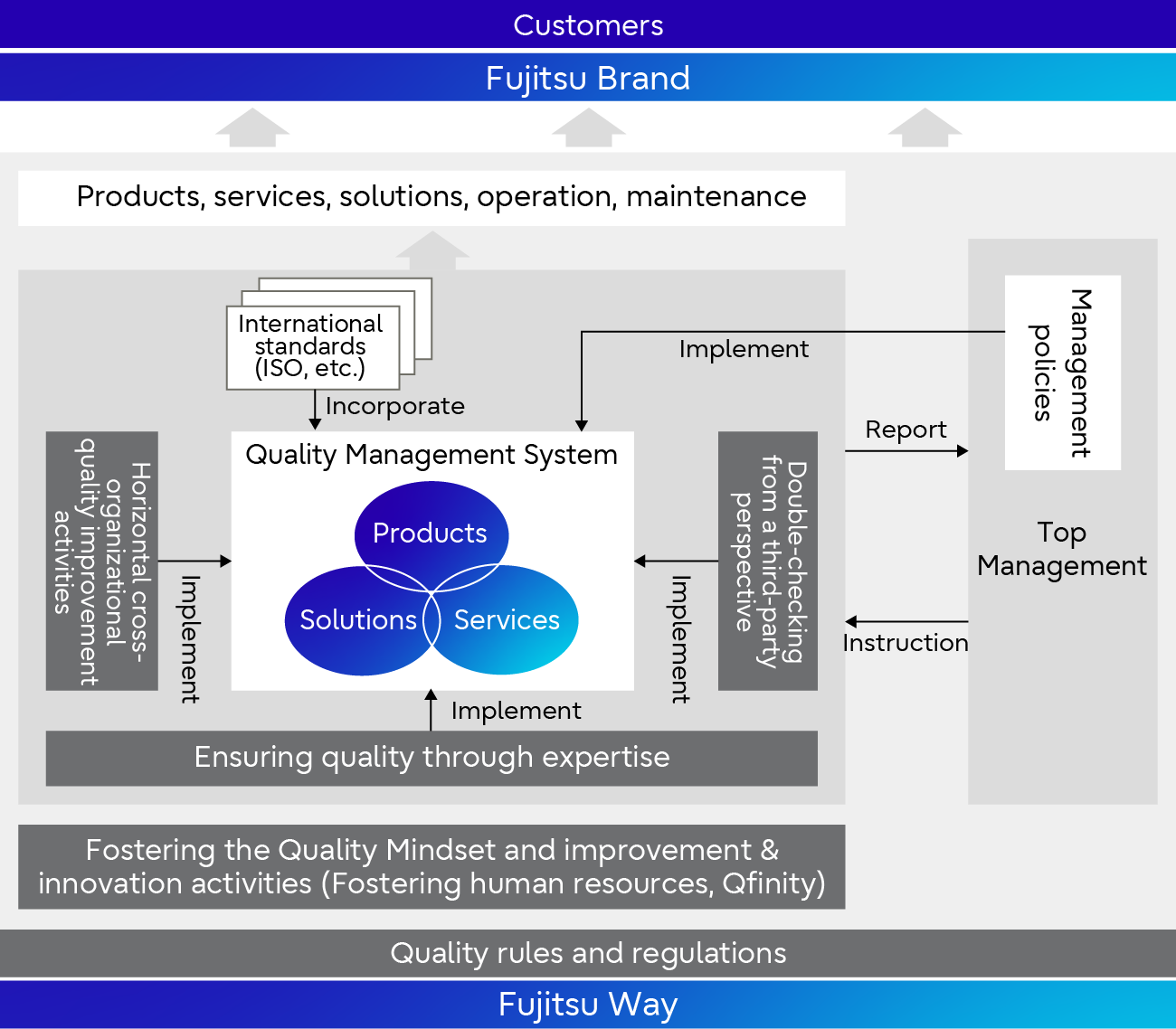

In order to provide a level of quality for our products and services which meets the needs and expectations of our customers in a consistent way, it is essential for us to coordinate with various organizations inside and outside Fujitsu—including business units, common business units, and business partners—from planning and design through development, manufacturing, testing, sales, operations, and up until maintenance. Frameworks and mechanisms to integrate these organizations are essential as a foundation for our efforts.

This is why we built our Quality Management System (QMS): to coordinate among these business units as appropriate for the product or service. Our QMS periodically verifies the progress in light of international certification standards such as the ISO in the aim of achieving process improvements to realize even higher quality.

Companywide Quality Improvement Cycle

Companywide Quality Improvement Cycle

Companywide Quality Improvement Cycle

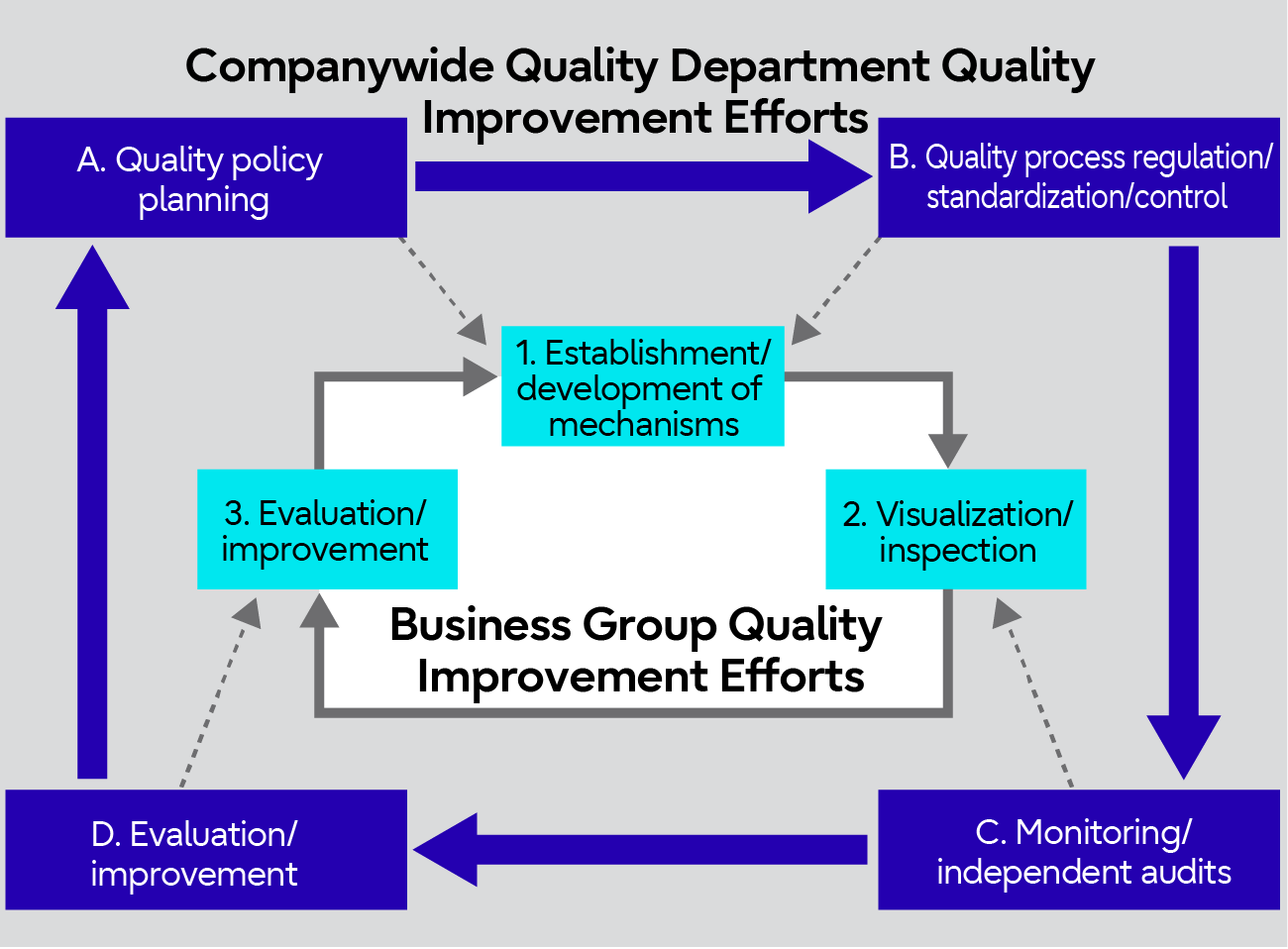

The Fujitsu Group’s quality improvement efforts consist of activities based on the Quality Policy by our Companywide Quality Department (Companywide Quality Department Quality Improvement Efforts in the diagram below) and activities to develop and implement quality management systems for each business group (Business Group Quality Improvement Efforts sections of the Companywide Quality Improvement Cycle diagram). These elements turn the cycle, with the entire Group working collaboratively and strategically to improve quality.

A. Quality policy planning

Quality objectives are set and reviewed, and quality strategies and policies for achieving them are planned and rolled out across the entire Fujitsu Group. In addition, we monitor and manage activities to ensure they are conducted in accordance with our Quality Policy.

B. Quality process regulation/standardization/control

Based on our Quality Policy, we are making progress with the standardization of specific processes and techniques in key areas targeted for improvement. We implement and control these standards at the locations where we operate. Additionally, also in line with our Quality Policy, we promote activities to improve quality across our business groups.

Furthermore, in addition to developing and disseminating quality-related standards, we also share best practices derived from successful projects, so that they can be widely utilized. Further, we promote the sharing of knowledge and project standardization through lessons learned from unsuccessful projects in a manner readily accessible to anyone.

C. Monitoring/independent audits

We monitor the projects of each business group, identify risks to quality at an early stage, escalate issues found, and implement countermeasures as needed. Any concerns regarding quality are addressed by a third party, who audits / conducts an inspection of the items involved, whereby we carry out corrections and improvements.

<In the event of a serious quality issue with any product/service we provide our customers>

Following the Risk Management Regulations, the matter is immediately reported from the field to the Risk Management & Compliance Committee at the Fujitsu Headquarters. Under the direction of the Committee, the relevant departments address the incident jointly and consider ways to prevent recurrence. The recurrence prevention measures are shared with other departments through QMR in an effort to prevent the same incident from occurring at other Fujitsu Group companies.

D. Evaluation/improvement

We regularly examine and analyze our approach to quality and consider additional measures if necessary, directing the QMR to make improvements based on the business characteristics of each organization.

After reporting updates to executive management on a regular basis, action is taken following their decision making and instructions.

Additionally, through Qfinity (Note 1) activity, good/best practices are commended and shared across the entire Fujitsu Group to increase the level of quality throughout the Group.

- Note 1:Qfinity

Qfinity, an internal branding term which combines the words “quality” and “infinity,” represents the DNA of the Fujitsu Group: the “infinite pursuit of quality by each and every employee.” Qfinity is an improvement and innovation activity launched throughout the Fujitsu Group in FY 2001 to continuously improve the quality of products and services, with each and every employee taking a central role. Through Qfinity, we promote quality improvement activities in each workplace and engage in quality improvement of products and services.

Quality Governance

Under the CQO, we are working to strengthen quality governance across the Fujitsu Group as well as prevent major incidents from reoccurring and enhancing the quality of products/services.

The process of strengthening quality governance involves rolling out a common platform to assess quality risk and the quality assurance process that supports service delivery within the Fujitsu Group to correctly assess risks and take thorough action against it.

As the number of challenges in new area of business increases and information systems become more complex, we use these mechanisms as a base to make swift and appropriate decisions and prepare for a variety of risks.

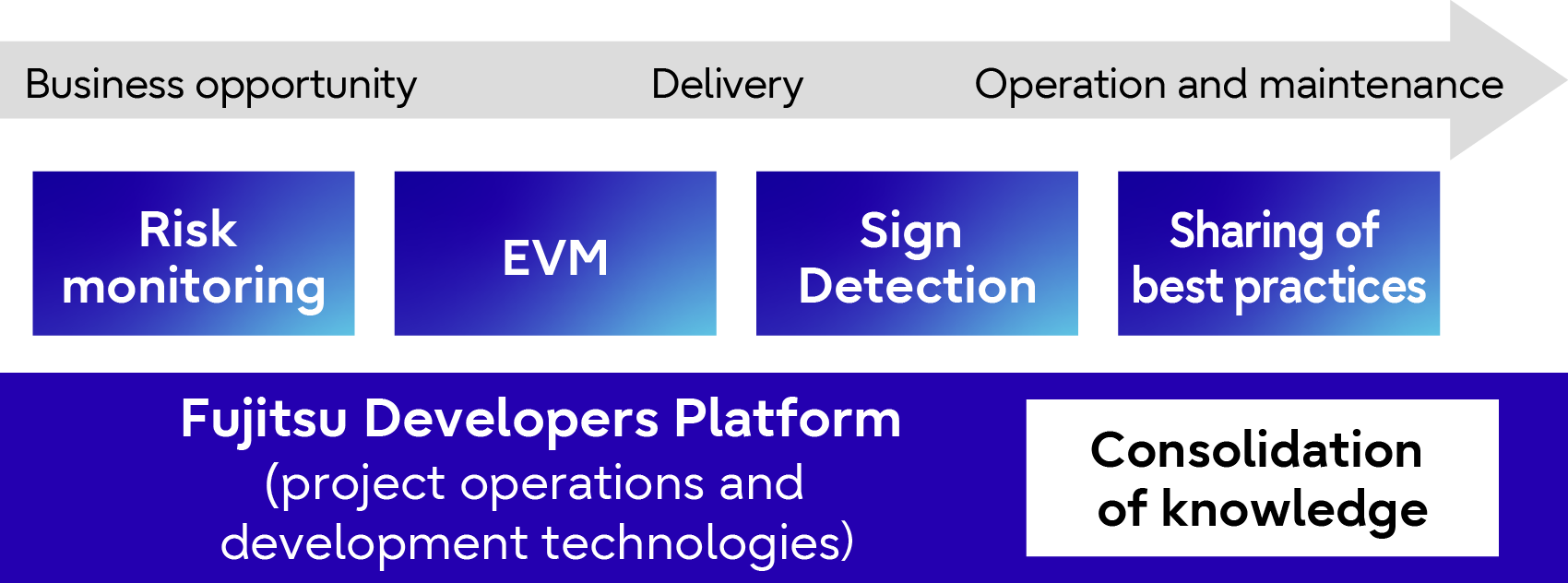

Strengthening the Design/Operation Platform Supporting Quality Governance and Risk Monitoring

Mechanism for Objectively Assessing Field Decisions

Mechanism for Objectively Assessing Field Decisions

We will consolidate quality-related information that we obtain in the development field, such as progress of development projects, test density, and defect detection rate, onto our common platform, Fujitsu Developers Platform. By combining this information with Earned Value Management (EVM) and quality indicators and conducting timely analysis, we will build a mechanism for assessing the quality and delivery decisions in the development field in a more objective manner.

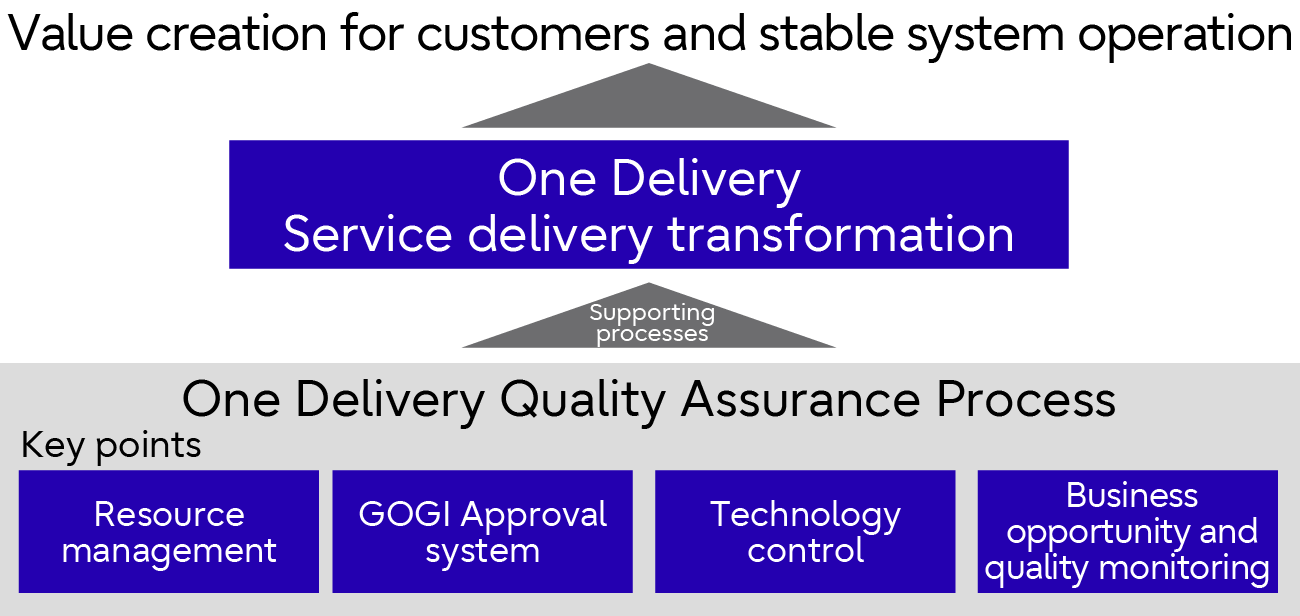

Quality Assurance Processes That Support Service Delivery

One Delivery Quality Assurance Process

One Delivery Quality Assurance Process

To provide customers with higher value than ever before and ensure stable system operation, we are moving to the “One Delivery” project structure—a new type of service delivery that is not organization-dependent. One Delivery manages projects in accordance with the shared “One Delivery Quality Assurance Process” to enable centralized risk management.

The One Delivery Quality Assurance Process embodies four key steps based on past quality issue trends. First, “Resource management” aims to prevent skills mismatch and similar problems. Next, the “GOGI Approval system” determines the promotion of business opportunities and projects from an objective and multifaceted perspective. “Technology control” then aims to improve technological appropriateness and feasibility. Finally, through “business opportunity and quality monitoring”, we detect at an early stage those projects with potential troubles.

We are working to apply and improve the One Delivery Quality Assurance Process, enabling the entire Group to provide higher-quality, more stable services.

FY 2023 Performance

Violation of Laws and Regulations Concerning Product Safety

- Violation of laws and regulations concerning product safety: 1 incident (Electrical Appliance and Material Safety Law: Non-compliance with safety design requirements (corrected))

Disclosure of Information Related to Product Safety

- Number of disclosed issues: 0 major product incidents

- Important notices concerning product safety

- Prevention Measures for Laptop Battery Ignition Incidents

On three previous occasions, Fujitsu has asked customers to exchange and return battery packs in order to prevent the spread of ignition incidents due to the possibility that foreign matter had contaminated the interior of the battery during the battery pack manufacturing process.

At the same time, however, although extremely rare, there have been cases of ignition occurring in battery packs outside those covered by the returns and exchanges.

It has been found that limiting the phenomena that increase the internal pressure of batteries is an effective measure in preventing these types of ignition incidents.

Since February 9, 2017, Fujitsu has been offering a "Battery Charging Control Update Tool" through its website for its laptop PCs launched between 2010 and 2016. In addition, since November 2018, Fujitsu has been distributing the Battery Charging Control Update Tool via Microsoft’s Windows Update service to the laptop PCs of all those affected in order to ensure all customers using the affected laptop PCs apply the update.

Non-legal compliance violations related to product safety and information/labeling violations

- Product information and labeling violations: 0

- Violation of the Foreign Exchange and Foreign Trade Act: 1 incident (Documentation errors at the time of compliance evaluation (corrected))

ISO9001 / ISO20000 Certification Status

Fujitsu is continuously working to improve processes under the QMS (items below as of September 2023).

- ISO9001: 21 divisions certified

- ISO20000: 5 divisions certified