- Fujitsu Manufacturing Solutions

- Offerings

- Production Preparation Sophistication Offering

- Upgradation of cost and production Offering

- Solutions

- Fujitsu Application for SAP® Solutions

- Production Planning

Fujitsu Application for SAP® Solutions Detail Scheduling Template - Build-to-order manufacturing

Fujitsu Application for SAP® Solutions Mass Customization Template - Actual Cost

Fujitsu Application for SAP® Solutions Actual Costs Template - SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)

- SAP® Digital Manufacturing (SAP DM)

- SAP® Integrated Business Planning (SAP IBP)

- SAP® Portfolio and Project Management (SAP PPM)

- Case study

- SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)

- Kawasaki Heavy Industries, Ltd.

- Kawasaki Heavy Industries, Ltd. (Fujitsu Uvance)

- Kawasaki Heavy Industries, Ltd. (SAP Website)

- SAP® Digital Manufacturing (SAP DM)

- Anaplan

- Fujitsu Supply Chain Planning Solutions

(Old name: FUJITSU Enterprise Application GLOVIA smart PROFOURS

FUJITSU Manufacturing Industry Solution COLMINA scheduler / PSI)

- FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES Innovative Case Study Report on Production Planning Operations in the Global Supply Chain GLOVIA smart PROFOURS (PDF)

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES (YouTube)

- Tohshin Seiki Co.,Ltd. (PDF)

- RISU PACK CO., LTD. (PDF)

- GOLD PAK CO., LTD. (PDF)

- Fujitsu Limited (PDF)

- Fujitsu Supply Chain Planning Solutions

- Fujitsu ERP Solutions for Process

(Old name: FUJITSU Enterprise Application GLOVIA ProcessC1)

- TOAGOSEI CO., LTD. (PDF)

- ASAHI BREWERIES, LTD. (PDF)

- NIHON NOHYAKU CO.,LTD. (PDF)

- Nippon Light Metal Company, Ltd. (PDF)

- ADEKA Corporation (PDF)

- Showa Denko K.K. (PDF)

- Fujitsu Digital Manufacturing FJVPS

- Fujitsu ERP Solutions for Process

- Catalog

- List of introductory materials on Planning Sophistication Offering

- Supply Chain Planning Solutions for Profit Maximizing S & OP Processes

SAP® Integrated Business Planning (SAP IBP) - Integrated Production Planning Solution for Supply Chain DX

GLOVIA smart PROFOURS

- List of introductory materials on Manufacturing execution management sophistication Offering

- List of introductory materials on Upgradation of cost and production Offering

- List of introductory materials on Upgradation of cost Offering

- For SAP deployment users

Cost / Profit and loss management solutions

Fujitsu Application for SAP® Solutions Actual Costs Template

- List of introductory materials on Upgradation of production Offering

- Fujitsu best add-in solution for flexible use of SAP

Fujitsu Application for SAP® Solutions Mass Customization Template - An ERP solution for Assembly Manufacturers Realize Mass Customization through Product Configuration Management

Fujitsu Application for SAP® Solutions Mass Customization Template (SIEMENS) - Provided by Fujitsu SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) - Solutions to manage all multiple parallel planning, development, and investment projects

SAP® Portfolio and Project Management (SAP PPM) - Fujitsu’s SAP Manufacturing Solutions

- Video (YouTube)

- List of videos (YouTube) related to Planning Sophistication Offering

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES

- Fujitsu Manufacturing DX journey to the best

- An Integrated Planning and Management Solution “PROFOURS” : A reliable field partner

- GLOVIA smart PROFOURS - Integrated production planning system for improving work efficiency

- Production Scheduling Software " Fujitsu Enterprise Application GLOVIA smart PROFOURS"

- List of videos (YouTube) related to Upgradation of cost and production Offering

- Fujitsu Manufacturing DX journey to the best

- Fujitsu Application for SAP Solutions makes mass customization for manufacturing possible

- Fujitsu Application for SAP® Solutions Mass Customization Template

~Product Concept Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Quotation Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Order Navigator Version~ - Introduction Fujitsu Manufacturing Industry Services

- Fujitsu Transforming the future of manufacturing

- List of videos (YouTube) related to Manufacturing execution management sophistication Offering

- Fujitsu Manufacturing DX journey to the best

- How to keep manufacturing operations compliant

- Smart Manufacturing Customer References with COLMINA and SAP Offerings ”Collaboration with SEMENS”

- FNC uses Fujitsu SAP to build the factory of the future

- Reimagine your business with Fujitsu and SAP : KAWASAKI case study

- Transform your manufacturing to next generation with Fujitsu SAP Industry 4.0

- SAP® Manufacturing Integration and Intelligence (SAP MII) Solution proposed by FUJITSU

- Events and Seminars

Realization of mass customization support

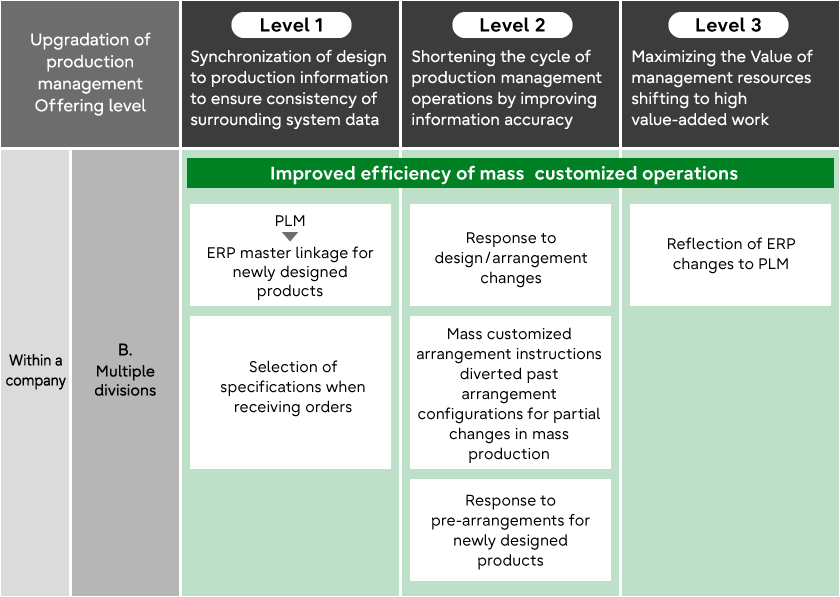

Upgradation of production Offering

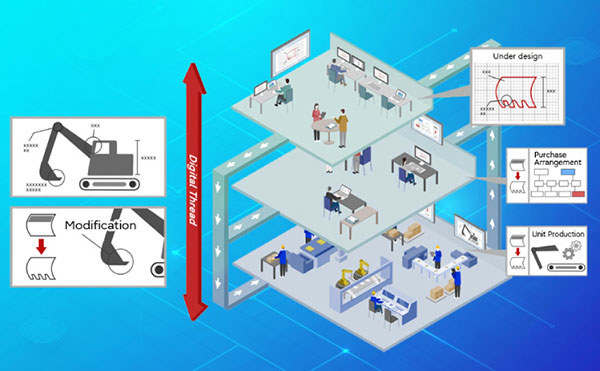

What is the Upgradation of production Offering ?

In the VUCA era, there is a need for a production format based on mass customization that can accommodate specification changes as necessary to meet customer needs. In the Upgradation of production Offering, efficient mass customization is becoming a requirement for manufacturers to survive. Fujitsu offers production management solutions utilizing SAP.

What are the challenges in mass customization?

With the diversification of customer needs, the number of companies handling individual specification products is increasing every year, and for customers in the assembly and manufacturing industry, frequent specification changes right up to the delivery date have become a bottleneck, placing a particularly heavy burden on front-line operations such as design and sales (estimation).

Upgradation of production Offering can achieve

Offering value for SAP S/4 HANA®

SAP S/4HANA® provides usability that supports the complex operations of manufacturing sites more efficiently and flexibly to customers in the manufacturing industry that have already implemented SAP S/4HANA® or considering implementing SAP S/4HANA®. "Mass customization" can be achieved by responding quickly to frequent customer requests, such as reducing the workload of front desk operations and shortening work cycles.

Realization of mass customization support

Upgradation of production solutions

Business example of Upgradation of production introduction

Watch the video "Upgradation of production"

Download the free catalog here

Fujitsu best add-in solution for flexible use of SAP

Fujitsu Application for SAP® Solutions Mass Customization Template

An ERP solution for Assembly Manufacturers

Realize Mass Customization through Product Configuration Management

Fujitsu Application for SAP® Solutions Mass Customization Template (SIEMENS)

Provided by Fujitsu SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)

Solutions to manage all multiple parallel planning, development, and investment projects

SAP® Portfolio and Project Management (SAP PPM)

Fujitsu’s SAP Manufacturing Solutions

Enquiries and consultation about Fujitsu Digital Manufacturing FJVPS

Company uses SSL technology for security purposes.