Kawasaki Heavy Industries, Ltd.

Introducing SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) as a pioneer in the world.

Aim for a complete manufacturing process

Challenges of Kawasaki Heavy Industries

Kawasaki Heavy Industries, Ltd. Aerospace Systems Company, which is one of Japan's leading aircraft manufacturers, is engaged in the development and manufacture of aircraft for the Ministry of Defense and the international development and production projects of commercial aircraft such as Boeing. As part of its future-oriented global strategy, the company has introduced "SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)" as a pioneer in the world to create a foundation for realizing comprehensive information from design to manufacturing shop floor. Development is currently steadily progressing toward the Go-live of SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) around the summer of 2020.

| Company Information | |

|---|---|

| Company name | Kawasaki Heavy Industries, Ltd. |

| Industry | Mobility (Aerospace, Rail, Marine), Energy, Industrial Equipment, Leisure |

| SAP product | SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) |

- ChallengesWorkers required considerable effort with communication to the shop floor when technical requirements such as drawings and specifications were changed, and with paper-based and manual management of recording manufacturing results.

- BenefitsTo be able to link via data from Design stage to Final manufacturing process, Share them in real time, and strictly be managed changes in manufacturing.

- ChallengesDue to paper-based management, worker required to have time and effort to find the necessary document on the shop floor.

- BenefitsSince the manufacturing information has been converted into data, the time and effort to find necessary paper documents has been greatly reduced, and improved work performance.

- ChallengesOne-stop Production information and Process visualization

- BenefitsImprovement of Production quality and Promotion of work style transformation

Background

Renewal of manufacturing process management base to strengthen international competitiveness

The design and manufacture of modern aircraft, which consists of extremely complex processes, is supported by IT in a wide variety of areas.

Kawasaki Heavy Industries, Ltd. Aerospace Systems Company (hereinafter referred to as Kawasaki Heavy Industries), one of Japan's leading aircraft manufacturers, traditionally positioned it as an important management resource to win the competition in the global market, where the use of ICT is changing drastically.

In 2009, we were one of the earlier company to introduce SAP ERP not only in the accounting field but also in the manufacturing process in general, and since then, we have continued to work on process integration throughout the organization and have achieved good results.

Mr. Akihito Sakai, Director and Doctor of Engineering (in charge of SCM & IOT, Gifu Factory), said that the background to the decision to introduce SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) as a new management platform this time was the "flow down of technical requirements", which is an essential issue in the aircraft business..

In aircraft manufacturing, changes in "technical requirements" such as drawings and specifications must be immediately communicated to shop floor and all must be recorded.

Moreover, these management statuses need to be disclosed immediately at the request of customers and certification bodies. Traditionally, the company has done many of these complex tasks manually using paper-based documents.

"We have a production system based on our own idea called KPS (Kawasaki Production System), and we are working on improvement activities at the production shop floor every day.

This activity is a very complicated task of changing the shop floor works and improving productivity while strictly ensuring the "flow down of technical requirements".

Paper and manual based management required a great deal of effort and was reaching its limits. The ongoing renewal of the manufacturing management infrastructure aims to meet the requirements of customers and certification bodies more rigorously and quickly, including the flow down of technical requirements, while at the same time saving labor and further improving KPS.

In addition, aircraft manufacturing management tends to be partial optimization due to depend on workers professional skills and knowledge.

Shifting these workers depended manufacturing to overall optimal management based on data was also an important issue in enhancing international competitiveness. (Mr. Sakai)

Kawasaki Heavy Industries, Ltd.

Kawasaki Heavy Industries, Ltd.

Deputy General Manager, Production Division, Aerospace Systems Company

(Gifu Factory, SCM & IOT) Director / Doctor of Engineering

Mr. Akihito Sakai

Details

SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) that realizes the whole process from design to manufacturing shop floor

Kawasaki Heavy Industries, has decided to build a new manufacturing management platform that supports the strengthening of international competitiveness, then has launched the "Smart-K" project and solicited proposals from major IT vendors.

At this time, Fujitsu and SAP Japan proposed SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO), which realizes information management of all processes from design to manufacturing shop floor at once.

However, SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) had no implemented results in globally as of 2018 when both companies proposed, and it was difficult to decide that there was a lack of information to decide to introduce it.

The final decision was greatly supported by the discussion, which set up by Fujitsu and SAP Japan, between key users of business department and IT department of the "Smart-K" project and the development team of SAP headquarters.

“We heard a detailed story from the developer at the German headquarters and found that SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) has the necessary functions to link all manufacturing data from design to shop floor.

In order to promote KPS, which is our production control concept, SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) has required functions that be able to link from the design stage to the final manufacturing process via data, share it in real time, and strictly manage changes. It met the requirements "(Mr. Sakai)

In addition, because of comprehensive evaluation of Fujitsu's wide range of knowledge and abundant achievements in the manufacturing industry, and its challenging attitude toward projects that are rare in the world, Kawasaki finally decided to adopt SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO).

The project kicked off in October 2018 proceeded to requirements definition and business design, and as of October 2019, this design has been completed and development is proceeding at a rapid pace.

The project is scheduled Go-live in some manufacturing processes around the summer of 2020, and after that, it will take about a year and a half to complete the deployment to all shop floor while gradually expanding the usage departments.

Benefits of the solution

The key to success is Continuous system optimization through functional improvement requests to SAP in deep relationship

With the introduction of SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO), it is a big evolution that all production information in Kawasaki Heavy Industries' aircraft manufacturing can be connected through data in a straightforward manner and the process can be visualized.

This has important implications for reliably responding to the flow down of technical requirements and increasing the trust of customers.

In addition, the most big and detailed result from shop floor is the improvement of work efficiency brought about by the shift to paperless work.

By converting all production information into data, the time and effort required to find the necessary paper documents can be greatly reduced in shop floor.

“If we can use the system with familiar devices such as smartphones and tablets, we should be even more productive.

To be able to recognize these on-site movements for managers in real time, we can expect to strengthen the management organization. "(Mr. Sakai)

For Kawasaki Heavy Industry, the introducing new system is not goal, but only the process.

Especially for SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO), which has a small result of introducing even globally, continuous system optimization and accumulation of know-how will affect future investment value.

In the current ECC 6.0, the number of add-on programs tended to increase with requests from users. The key to success the project is, how we can improve the functions of SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) itself by close communication with the development team at the SAP headquarters together for the future.

The key is to get rid of it. "(Mr. Sakai)

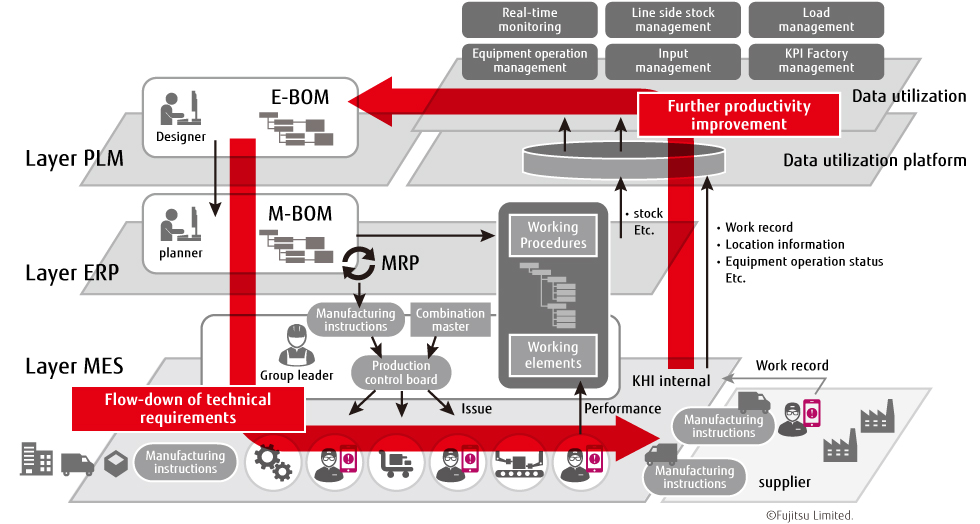

System Diagram

System Diagram

Future outlook

Expected to be the platform for work style transformation in addition to the high-level data utilization

Go-live scheduled around summer of 2020. Kawasaki Heavy Industries already begun to design a roadmap for the future in paradelle.

To make the best use of the functions of SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO), it is necessary to make efforts to utilize the huge amount of data accumulated in the system, and to start full-scale development and operation of the data utilization infrastructure.

Mr. Sakai talks about Fujitsu's role as a partner in this roadmap, as following.

“SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) is still a developing solution.

Fujitsu is the partner who know our manufacturing deeply and continues to develop together. We expect to Fujitsu the front of influential counterpart in communicating various functional improvement requests to the SAP headquarters in the future.

This roadmap has already been shared with system users, and the mindset for utilizing SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) is extremely high.

Comprehensive production information and visualization of processes will be a great impact not only for improving production quality but also for proceeding work style transformation.

“Reduce the workload of Shop floor managers, strengthen collaboration, and increase motivation of workers.

I believe that SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) will be the foundation for thoroughly changing the mindset of the workers and promoting work style transformation. "(Mr. Sakai)

There is no doubt that SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) will be a major wing to support the leap into the future for the company's production management infrastructure renewal and work style transformation.

As of March 2021, this system is went-live and business starts with SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO).

Kawasaki Heavy Industries, Ltd.

| Established | October 15, 1896 |

|---|---|

| Capital | 104,484 million yen (as of March 31, 2019) |

| Consolidated sales | 1,594,743 million yen (fiscal year ending March 2019) |

| Number of consolidated employees | 35,691 (as of March 31, 2019) |

| Business | Development, manufacturing and sales of ships, railroad vehicles, aircraft and space equipment, industrial plants and environmental protection equipment, industrial machinery, motorcycles and general-purpose gasoline engines, construction, industrial precision machinery and robots under a 6-company system. |

| Website |  http://www.khi.co.jp/ http://www.khi.co.jp/ |

[Published in November 2019]