- Fujitsu Manufacturing Solutions

- Offerings

- Production Preparation Sophistication Offering

- Upgradation of cost and production Offering

- Solutions

- Fujitsu Application for SAP® Solutions

- Production Planning

Fujitsu Application for SAP® Solutions Detail Scheduling Template - Build-to-order manufacturing

Fujitsu Application for SAP® Solutions Mass Customization Template - Actual Cost

Fujitsu Application for SAP® Solutions Actual Costs Template - SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)

- SAP® Digital Manufacturing (SAP DM)

- SAP® Integrated Business Planning (SAP IBP)

- SAP® Portfolio and Project Management (SAP PPM)

- Case study

- SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO)

- Kawasaki Heavy Industries, Ltd.

- Kawasaki Heavy Industries, Ltd. (Fujitsu Uvance)

- Kawasaki Heavy Industries, Ltd. (SAP Website)

- SAP® Digital Manufacturing (SAP DM)

- Anaplan

- Fujitsu Supply Chain Planning Solutions

(Old name: FUJITSU Enterprise Application GLOVIA smart PROFOURS

FUJITSU Manufacturing Industry Solution COLMINA scheduler / PSI)

- FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES Innovative Case Study Report on Production Planning Operations in the Global Supply Chain GLOVIA smart PROFOURS (PDF)

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES (YouTube)

- Tohshin Seiki Co.,Ltd. (PDF)

- RISU PACK CO., LTD. (PDF)

- GOLD PAK CO., LTD. (PDF)

- Fujitsu Limited (PDF)

- Fujitsu Supply Chain Planning Solutions

- Fujitsu ERP Solutions for Process

(Old name: FUJITSU Enterprise Application GLOVIA ProcessC1)

- TOAGOSEI CO., LTD. (PDF)

- ASAHI BREWERIES, LTD. (PDF)

- NIHON NOHYAKU CO.,LTD. (PDF)

- Nippon Light Metal Company, Ltd. (PDF)

- ADEKA Corporation (PDF)

- Showa Denko K.K. (PDF)

- Fujitsu Digital Manufacturing FJVPS

- Fujitsu ERP Solutions for Process

- Catalog

- List of introductory materials on Planning Sophistication Offering

- Supply Chain Planning Solutions for Profit Maximizing S & OP Processes

SAP® Integrated Business Planning (SAP IBP) - Integrated Production Planning Solution for Supply Chain DX

GLOVIA smart PROFOURS

- List of introductory materials on Manufacturing execution management sophistication Offering

- List of introductory materials on Upgradation of cost and production Offering

- List of introductory materials on Upgradation of cost Offering

- For SAP deployment users

Cost / Profit and loss management solutions

Fujitsu Application for SAP® Solutions Actual Costs Template

- List of introductory materials on Upgradation of production Offering

- Fujitsu best add-in solution for flexible use of SAP

Fujitsu Application for SAP® Solutions Mass Customization Template - An ERP solution for Assembly Manufacturers Realize Mass Customization through Product Configuration Management

Fujitsu Application for SAP® Solutions Mass Customization Template (SIEMENS) - Provided by Fujitsu SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations (SAP PEO) - Solutions to manage all multiple parallel planning, development, and investment projects

SAP® Portfolio and Project Management (SAP PPM) - Fujitsu’s SAP Manufacturing Solutions

- Video (YouTube)

- List of videos (YouTube) related to Planning Sophistication Offering

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES

- Fujitsu Manufacturing DX journey to the best

- An Integrated Planning and Management Solution “PROFOURS” : A reliable field partner

- GLOVIA smart PROFOURS - Integrated production planning system for improving work efficiency

- Production Scheduling Software " Fujitsu Enterprise Application GLOVIA smart PROFOURS"

- List of videos (YouTube) related to Upgradation of cost and production Offering

- Fujitsu Manufacturing DX journey to the best

- Fujitsu Application for SAP Solutions makes mass customization for manufacturing possible

- Fujitsu Application for SAP® Solutions Mass Customization Template

~Product Concept Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Quotation Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Order Navigator Version~ - Introduction Fujitsu Manufacturing Industry Services

- Fujitsu Transforming the future of manufacturing

- List of videos (YouTube) related to Manufacturing execution management sophistication Offering

- Fujitsu Manufacturing DX journey to the best

- How to keep manufacturing operations compliant

- Smart Manufacturing Customer References with COLMINA and SAP Offerings ”Collaboration with SEMENS”

- FNC uses Fujitsu SAP to build the factory of the future

- Reimagine your business with Fujitsu and SAP : KAWASAKI case study

- Transform your manufacturing to next generation with Fujitsu SAP Industry 4.0

- SAP® Manufacturing Integration and Intelligence (SAP MII) Solution proposed by FUJITSU

- Events and Seminars

Visualizing the manufacturing site and solving problems

Manufacturing execution management sophistication Offering

News & Topics

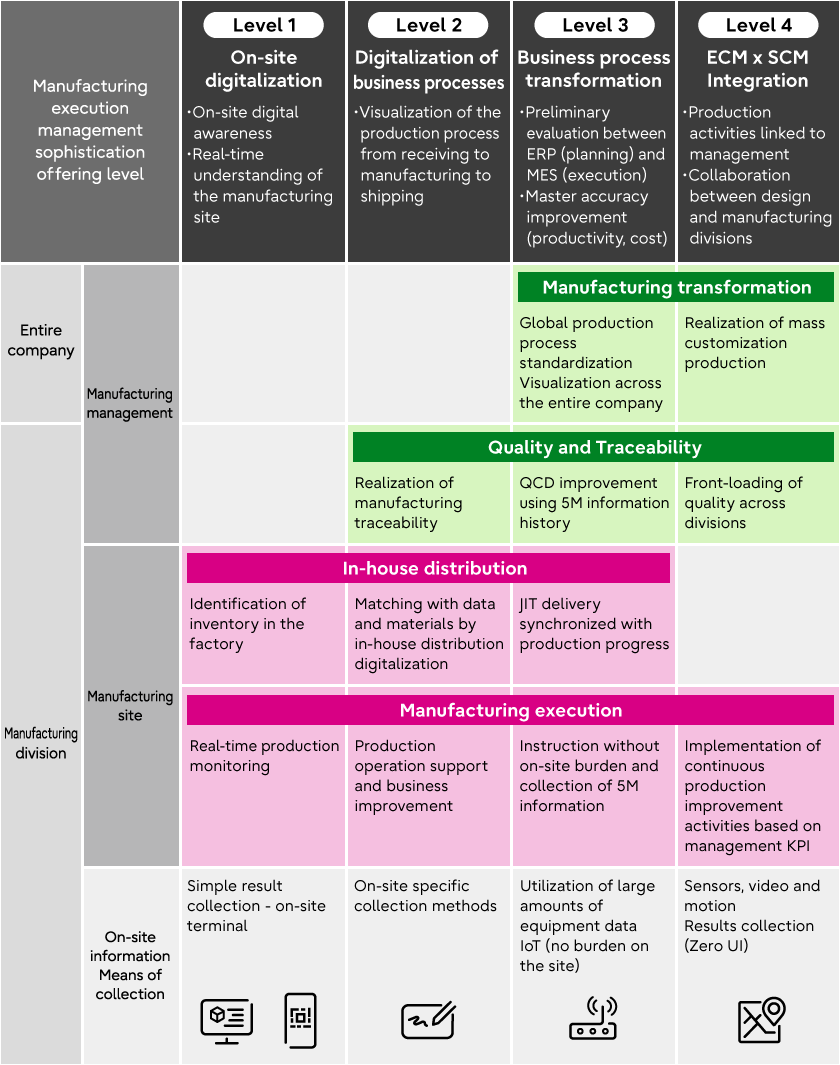

What is the Manufacturing execution management sophistication Offering?

In these uncertain times, manufacturing sites need to address a variety of issues by linking management and production activities, including issues such as a declining workforce and diversifying needs.Creating a data-driven manufacturing environment that enables the collection, analysis, and feedback of real-time onsite information from both inside and outside the company, and a company-wide PDCA cycle, leads to the advancement of the manufacturing site.Combining "standardized information," which is the basis for management decisions, with "real information" optimized for various forms of manufacturing, we support the realization of manufacturing sites that can keep up with changes.

What are the challenges you face in manufacturing execution management?

In addition to manufacturing information related to production, a variety of information is scattered around the manufacturing site, including information on workers, the site environment, and the location of people and goods.Simply collecting data recklessly is meaningless; it is important to link related information and transform it into valuable data.

Manufacturing sites are required to create systems that can respond immediately to change.

Manufacturing execution management sophistication Offering can be achieved

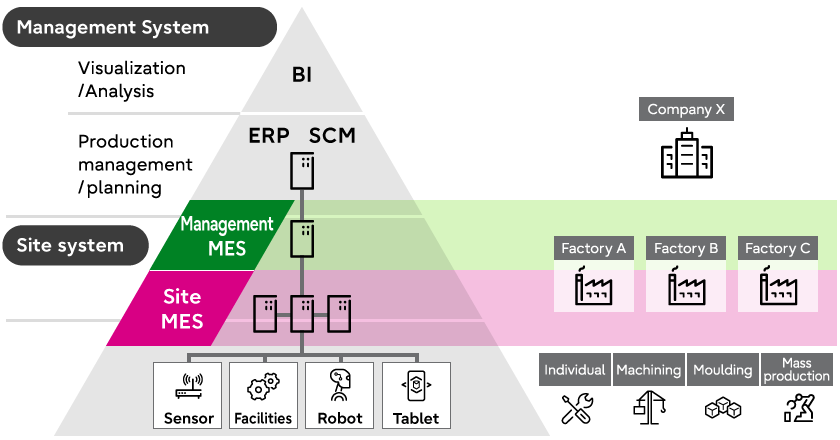

MES is defined by functions aimed at optimizing manufacturing operations, but the difficulty with MES is that the boundary between ERP and MES is blurred and variable, depending on organizational structure, requirements, and manufacturing processes.

In some cases, the ERP side of the MES covers areas close to manufacturing to a certain extent, and the rest is a field system that monitors progress based on actual results from the facilities. In other cases, the MES covers the planning layer, such as manufacturing planning and instruction management, while the ERP area only handles ordering.

In such a manufacturing site, there are areas where quality and business logic based on company-wide standards should be guaranteed as data and systems, and areas where speedy tracking of fluctuations and improvements should be made to support the manufacturing site.

Fujitsu defines MES by dividing it into two layers, "management MES" and "on-site MES,

Management of "standardized information" supporting the aggregation and analysis of information that forms the basis for management decisions,

Flexibly and smoothly fuse on-site MES information, which is "real information" optimized for various forms of manufacturing.

The MES is layered by "management MES" × "site MES".

Fujitsu's manufacturing environment that can keep up with changes

Achieve the customer's ideal image

Business x Offering Level x Solution

The offering combines Fujitsu's expertise and know-how with the manufacturing DX theme that customers would like to realize and four offering scenarios to propose optimal solutions for promoting DX.

Please feel free to consult us as consider the introduction utilizing existing system infrastructure can be done.

Responding to changes and creating new value through "management MES" and "on site MES"

Manufacturing execution management sophistication solutions from Fujitsu

Business example of Manufacturing execution management sophistication

Watch a video of how to solve the problems of the manufacturing industry

Download the free catalog here

SAP® Digital Manufacturing (SAP DM)

Manufacturing cluster that realizes manufacturing DX

Provided by Fujitsu SAP Manufacturing Execution System (MES)

Provided by Fujitsu

SAP Engineering Manufacturing Execution Solution

Enquiries and consultation about Fujitsu Digital Manufacturing FJVPS

Company uses SSL technology for security purposes.