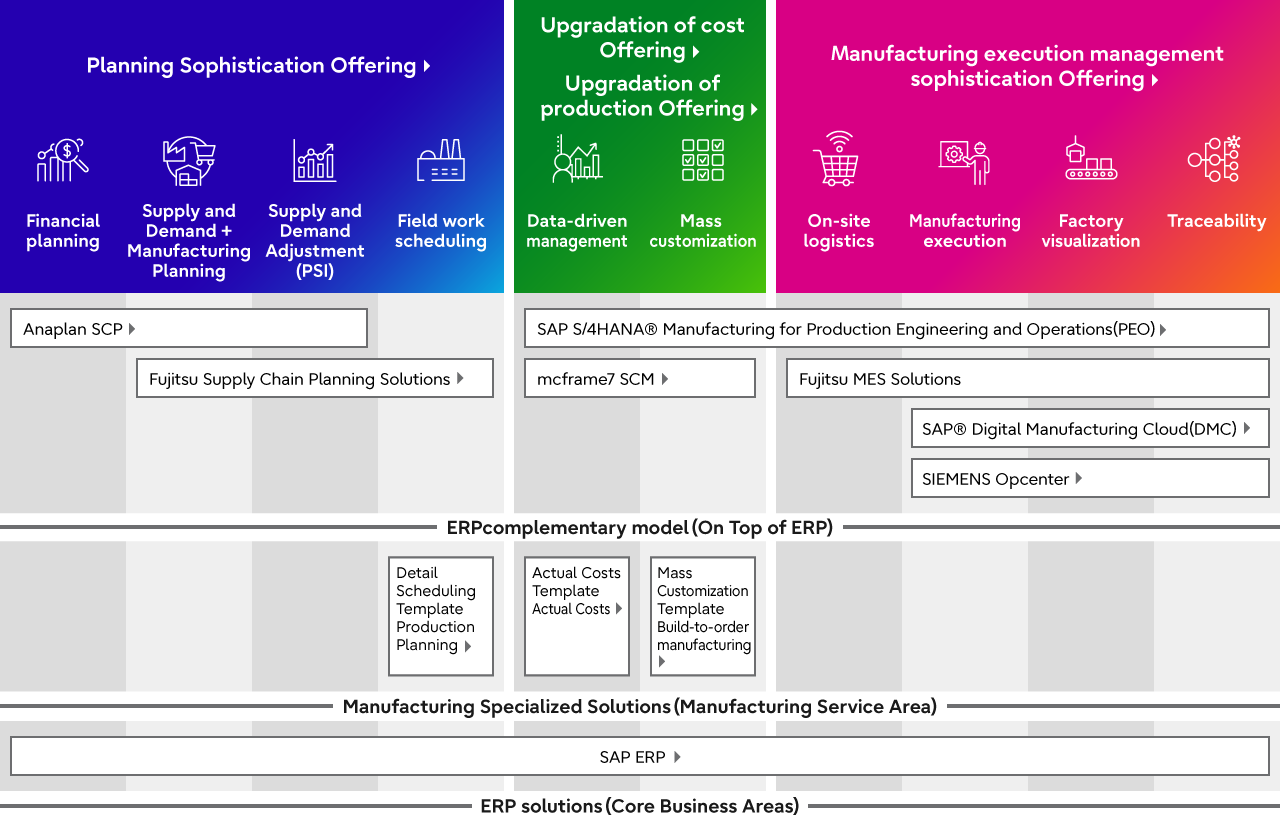

- Top SCM/ERP/MES solutions for manufacturing

- Offerings

- Upgradation of cost and production Offering

- Solutions

- SAP Manufacturing Solution

- Fujitsu SAP Manufacturing Solutions

- Fujitsu Application for SAP® Solutions

- Production Planning

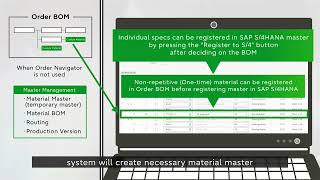

Fujitsu Application for SAP® Solutions Detail Scheduling Template - Build-to-order manufacturing

Fujitsu Application for SAP® Solutions Mass Customization Template - Actual Cost

Fujitsu Application for SAP® Solutions Actual Costs Template - SAP S/4HANA® Manufacturing for Production Engineering and Operations (PEO)

- SAP Manufacturing Execution System (MES)

- SAP Integrated Business Planning (IBP)

- SAP® Portfolio and Project Management (PPM)

- Case study

- SAP Engineering Manufacturing Execution Solution(PEO)

- Kawasaki Heavy Industries, Ltd.

- Kawasaki Heavy Industries, Ltd. (Fujitsu Uvance)

- Kawasaki Heavy Industries, Ltd. (SAP Website)

- SAP Manufacturing Execution System (MES)

- Fujitsu Supply Chain Planning Solutions

(Old name: FUJITSU Enterprise Application GLOVIA smart PROFOURS

FUJITSU Manufacturing Industry Solution COLMINA scheduler / PSI)

- FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES Innovative Case Study Report on Production Planning Operations in the Global Supply Chain GLOVIA smart PROFOURS (PDF)

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES (YouTube)

- Tohshin Seiki Co.,Ltd. (PDF)

- RISU PACK CO., LTD. (PDF)

- GOLD PAK CO., LTD. (PDF)

- Fujitsu Limited (PDF)

- Fujitsu Supply Chain Planning Solutions

- Fujitsu ERP Solutions for Process

(Old name: FUJITSU Enterprise Application GLOVIA ProcessC1)

- Fujitsu ERP Solutions for Process

- Catalog

- List of introductory materials on Planning Sophistication Offering

- Supply Chain Planning Solutions for Profit Maximizing S & OP Processes

SAP® Integrated Business Planning - Integrated Production Planning Solution for Supply Chain DX

GLOVIA smart PROFOURS

- List of introductory materials on Manufacturing execution management sophistication Offering

- Manufacturing cluster that realizes manufacturing DX

- Provided by Fujitsu SAP Manufacturing Execution System (MES)

- Provided by Fujitsu SAP Cloud Manufacturing Solutions (SAP DMC)

- SAP DMC Achieving DX Manufacturing beginning from a Small Start

- Provided by Fujitsu SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations

- List of introductory materials on Upgradation of cost and production Offering

- List of introductory materials on Upgradation of cost Offering

- For SAP deployment users

Cost / Profit and loss management solutions

Fujitsu Application for SAP® Solutions Actual Costs Template

- List of introductory materials on Upgradation of production Offering

- Fujitsu best add-in solution for flexible use of SAP

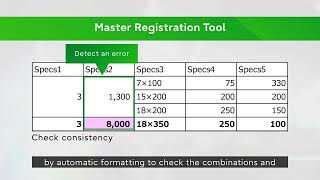

Fujitsu Application for SAP® Solutions Mass Customization Template - An ERP solution for Assembly Manufacturers Realize Mass Customization through Product Configuration Management

Fujitsu Application for SAP® Solutions Mass Customization Template (SIEMENS) - Provided by Fujitsu SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations - Solutions to manage all multiple parallel planning, development, and investment projects

SAP® Portfolio and Project Management - Fujitsu’s SAP Manufacturing Solutions

- Video (YouTube)

- List of videos (YouTube) related to Planning Sophistication Offering

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES

- Fujitsu Manufacturing DX journey to the best

- An Integrated Planning and Management Solution “PROFOURS” : A reliable field partner

- GLOVIA smart PROFOURS - Integrated production planning system for improving work efficiency

- Production Scheduling Software " Fujitsu Enterprise Application GLOVIA smart PROFOURS"

- List of videos (YouTube) related to Upgradation of cost and production Offering

- Fujitsu Manufacturing DX journey to the best

- Fujitsu Application for SAP Solutions makes mass customization for manufacturing possible

- Fujitsu Application for SAP® Solutions Mass Customization Template

~Product Concept Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Quotation Version~ - Fujitsu Application for SAP® Solutions Mass Customization Template

~Order Navigator Version~ - Introduction Fujitsu Manufacturing Industry Services

- Fujitsu Transforming the future of manufacturing

- List of videos (YouTube) related to Manufacturing execution management sophistication Offering

- Fujitsu Manufacturing DX journey to the best

- How to keep manufacturing operations compliant

- Smart Manufacturing Customer References with COLMINA and SAP Offerings ”Collaboration with SEMENS”

- FNC uses Fujitsu SAP to build the factory of the future

- Reimagine your business with Fujitsu and SAP : KAWASAKI case study

- Transform your manufacturing to next generation with Fujitsu SAP Industry 4.0

- SAP MII Solution proposed by Fujitsu

- Events and Seminars

FUJITSU Manufacturing DX journey to the best

SCM/ERP/MES solutions for manufacturing

We are committed to ensuring that our customers continue to use our ERP

We believe that what is required of ERP/SCM today are “change-resistant ERP/SCM” that is flexible enough to respond to changes in the social environment and business expansion, and “easy-to-use Enterprise Application Solutions” that ensure a high level of usability even as operations tend to become complex.

The key to this is "manufacturing knowledge".

Fujitsu, which is a manufacturing company itself, has "DNA" as a manufacturing company, and has three commitments that make use of the manufacturing knowledge cultivated through many years of ERP introduction experience.

We are committed to ensuring that our customers continue to use our ERP.

As a unique manufacturing company ERP vendor, we provide strong backup support for our customers’ digital transformation.

What is Fujitsu’s Manufacturing Digital Transformation (DX) ?

The important factors in manufacturing Digital Transformation (DX) are the business processes of the engineering chain, such as the design BOM and the manufacturing BOM, which are involved in the manufacturing specifications and whose management has a very strong impact on the productivity and quality of manufacturing if they change.

A key point is how well the engineering chain, which covers design, production, and production site operations on the blue vertical axis, is communicated by digital information and how well it is managed to keep pace with changes.

In terms of strengthening the digital thread/digital driven operation, Fujitsu believes that the key to manufacturing Digital Transformation (DX) is the ability to use the same information to connect processes from the design BOM to the manufacturing site to speed up operations and to be able to analyze and ensure improved traceability through the effective use of data across processes.

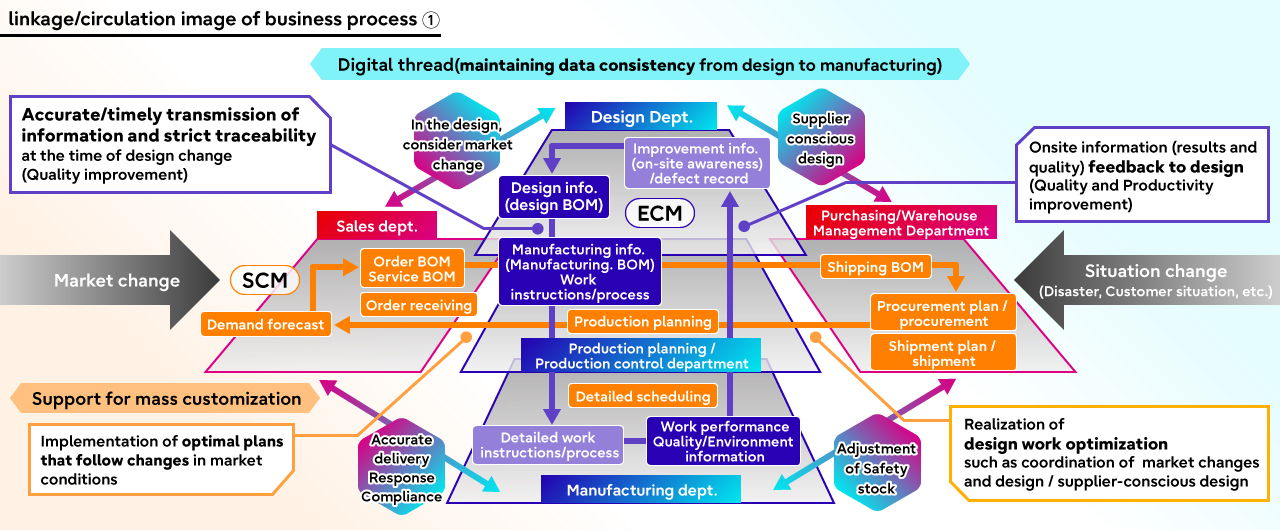

■Explanation of Business Process Coordination and Recycling Image (1)

- This figure explains manufacturing area DX conversion image that Fujitsu thinks.

- The blue line on the vertical axis represents business collaboration and circulation in the engineering chain.

- The line going from top to bottom indicates the design information such as design BOM, Manufacturing BOM, Work process etc. can be reliably and accurately transmitted to the manufacturing site as per work instructions. It shows the state in which a "digital thread" has been achieved by preserving nature.

- As a result, even in design change, the information can be transmitted accurately and timely. At the same time, strict traceability can be secured for changes, which has the advantage of improving quality.

- Further, the returning line from bottom to top indicates the state in which manufacturing performance and quality information, like manufacturing history and quality records, can be informed to the design process. With this, we aim to improve quality and productivity.

- On the other hand, the horizontal orange line represents business collaboration and circulation in the supply chain. By linking with the blue engineering chain, it will be possible to corelate with every process and follow changes in the market conditions by implementing optimal plans for mass customization, and optimization of design work. Through this we can manage Market design change or supplier-conscious design etc.

In this way, by linking the engineering chain and the supply chain, it is possible to improve productivity and quality, which are important in the world of manufacturing. Through this, resilient environment can be created which flexibly responds to change.

It is related to the keywords of the business leaders survey responses "change resilience importance" and "data-driven management".

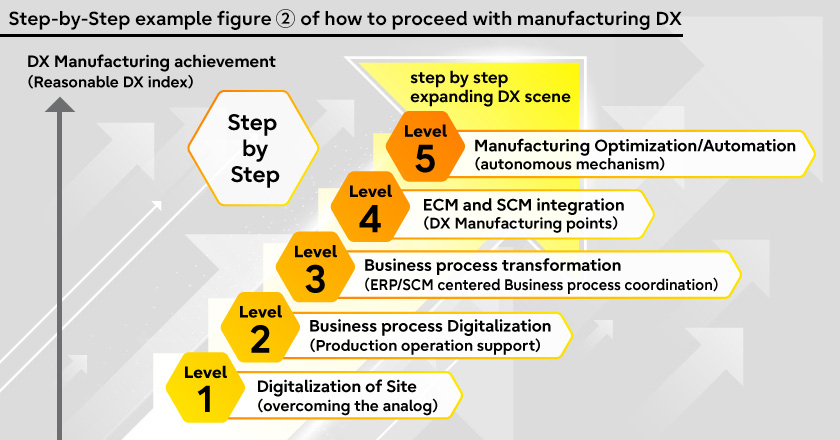

■Explanation of step-by-step example figure (2) of how to proceed with manufacturing DX

In order to realize DX, it is important to take a reasonable approach to DX by understanding and benchmarking one's own current level.

For example, here is a graphic representation of the concept of DX achievement as an indicator for each customer to realize DX for their own operations and industry.

- At level 1 of achievement toward DX is defined as a state in which some processes, such as manufacturing instructions and quality management, have been able to move away from analog mechanisms such as paper and Excel.

- At level 2, these operations are defined as a state where digitization is planned for each operation process, such as "manufacturing execution management".

- At level 3, it is defined as a state in which business processes, such as production management and manufacturing execution management, can cooperate with each other, centering on ERP and SCM business processes.

- At level 4, the ability to integrate SCM and ECM, from the design described as the key to manufacturing DX to manufacturing execution management.

- Level 5 refers to the realization of mechanisms that are some degree of autonomy, such as optimization and automation. This level is not something that can be raised suddenly, but rather something that can be aimed at after achieving Level 4.

In this way, the key point is to define the level based on the step-by-step concept of digitization first, then connect the processes, and then autonomously generate value from the connected results. By understanding and benchmarking the current level of DX achievement, a reasonable approach to DX can be found.

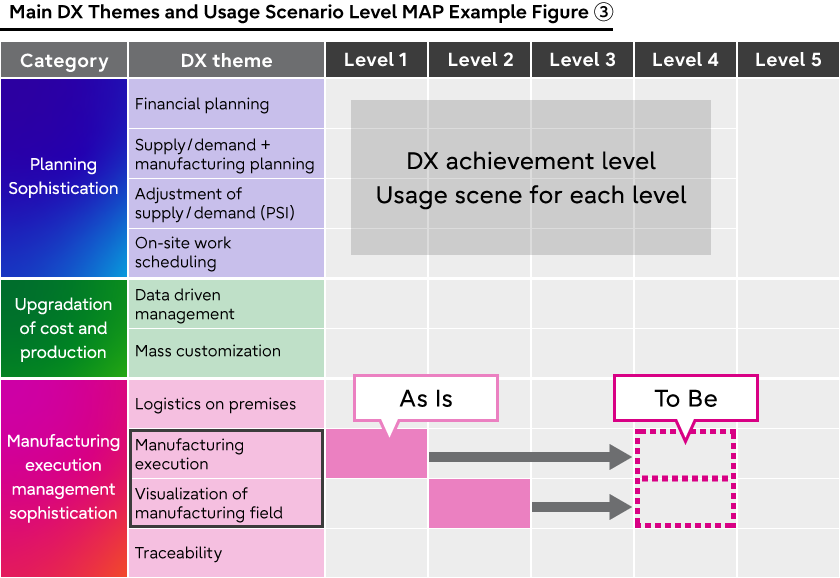

■Main DX Themes and Usage Scenario Level MAP Example Figure (3)

- The Step-by-Step approach explained so far, defines a level for each category and DX theme, and summarizes and organizes the degree of DX achievement at each level in the form of usage scenarios.

- The key point of the Step-by-Step approach is to share the current state of each customer based on this "usage scene level" and share the "theme" and "level" to be raised in the future. For example, by defining the desired state level 4 from the current state level 1, while realizing the effects, the path is improved each time and approaches the ideal state.

DX manufacturing themes and issues to realize management reform in the manufacturing field

At Fujitsu, management reform themes are divided into 3 categories, and 10 major manufacturing DX themes have been established to provide guidelines for systematization and business reform. By building a business process model that utilizes the solutions needed to realize each theme, and can achieve the customer's DX manufacturing.

It is important to improve the planning process in order to quickly recognize changes and respond to them immediately.

The "Planning Sophistication Offering" connects planning between companies and within companies, and provides a mechanism to speed up decision-making throughout the entire supply chain.

Financial PlanningWith top-down and bottom-up two-way communication, a financial (budget) plan is created that is consistent throughout the company and conduct simulations that are linked to daily operational plans. Efficient information sharing throughout the company and visualization of KPIs that maintain consistency between management and worksites contribute to maximizing profits.

Financial PlanningWith top-down and bottom-up two-way communication, a financial (budget) plan is created that is consistent throughout the company and conduct simulations that are linked to daily operational plans. Efficient information sharing throughout the company and visualization of KPIs that maintain consistency between management and worksites contribute to maximizing profits. Supply and Demand + Manufacturing PlanningThe supply and demand balance adjustment, which includes not only products but also work-in-progress and intermediate products, and more detailed manufacturing plans that take site restrictions into consideration are mutually linked to realize smooth simulations of changes in demand, site troubles, and other situations.

Supply and Demand + Manufacturing PlanningThe supply and demand balance adjustment, which includes not only products but also work-in-progress and intermediate products, and more detailed manufacturing plans that take site restrictions into consideration are mutually linked to realize smooth simulations of changes in demand, site troubles, and other situations.

Efficient information coordination between the head office and the field contributes to quick and optimal decision-making in response to change.

Supply and Demand Adjustment (PSI)Centrally manage sales, inventory, production, and procurement data, and visualize warnings in real time about changes in the situation. It enables automatic and manual scheduling of production and procurement plans while maintaining inventory balance, taking into account limitations such as plant loads and warehouse capacity.

Supply and Demand Adjustment (PSI)Centrally manage sales, inventory, production, and procurement data, and visualize warnings in real time about changes in the situation. It enables automatic and manual scheduling of production and procurement plans while maintaining inventory balance, taking into account limitations such as plant loads and warehouse capacity.

It contributes to the optimization of inventories by adjusting supply and demand to reflect changes in the situation immediately, and to the improvement of ability to respond quickly and flexibly to changes.

Field work schedulingIt aggregates detailed manufacturing limitations that differ from industry to industry, and specialist know-how. It can achieve automatic and manual scheduling that takes into account constraints and resources (people, factories, equipment loads).

Field work schedulingIt aggregates detailed manufacturing limitations that differ from industry to industry, and specialist know-how. It can achieve automatic and manual scheduling that takes into account constraints and resources (people, factories, equipment loads).

It contributes to eliminating the number of employees through centralized management of information and know-how, reducing the workload by planning automation, and improving the planning speed.Planning Sophistication Offering Details

As a result, it is possible to feed back the actual site results to design, eliminate defects, visualize production results, and respond to changes in a timely manner.

Data-driven managementIn the process industry, we deal with "fluctuations in raw material prices" such as rising prices of naphtha and imported raw materials, "discrepancies in actual production orders" due to manufacturing conditions such as seasonal fluctuations, and "complex production processes" due to inverted tree type production. There is a need for cost and profit/loss management that takes into account market fluctuations and industry characteristics.

Data-driven managementIn the process industry, we deal with "fluctuations in raw material prices" such as rising prices of naphtha and imported raw materials, "discrepancies in actual production orders" due to manufacturing conditions such as seasonal fluctuations, and "complex production processes" due to inverted tree type production. There is a need for cost and profit/loss management that takes into account market fluctuations and industry characteristics.

Support to customer's data-driven management, starting with cost and profit management that is directly linked to management.

Mass customizationThis solution is designed to help customers in the manufacturing industry achieve mass customization by eliminating the complexity of their work.

Mass customizationThis solution is designed to help customers in the manufacturing industry achieve mass customization by eliminating the complexity of their work.

Through integrated manufacturing solutions with SAP ERP, provide benefits such as "improved operational efficiency", "improved usability" and "use of the latest technology" for customers with various production models such as repeat order production, order specification production, and order design production.Upgradation of cost Offering DetailsUpgradation of production Offering details

Building a data-driven manufacturing environment that enables the PDCA cycle throughout the company, which enables the collection, analysis, and feedback of real-time on-site information from inside and outside the company, will lead to the manufacturing execution management sophistication.

It supports the realization of a manufacturing execution management that can handle changes by fusing "standardized information" that is the basis for management decisions and "real information" that is optimized according to various manufacturing forms.

On-site logisticsManages the location of "materials" (materials, intermediate products, finished products) at all production sites (in-house plants, external plants, etc.) and managing real time inventory information, the inventory of the entire factory can be managed. Will lead to the optimization and sophistication of in-plant logistics according to manufacturing.

On-site logisticsManages the location of "materials" (materials, intermediate products, finished products) at all production sites (in-house plants, external plants, etc.) and managing real time inventory information, the inventory of the entire factory can be managed. Will lead to the optimization and sophistication of in-plant logistics according to manufacturing.

In addition, by moving "things" associated with manufacturing, an environment will be provided where customer can concentrate on manufacturing by securing space at the work site and preventing human errors such as picking mistakes.

Manufacturing executionIt is the foundation for collecting, storing, and linking manufacturing information that supports the supply and engineering chains.

Manufacturing executionIt is the foundation for collecting, storing, and linking manufacturing information that supports the supply and engineering chains.

Provides instructions on design and work information to workers in a timely and easy-to-understand manner. Collects results in a way that does not place a burden on them. This is the first step toward digitalization of the workplace and sophistication of the manufacturing execution management.

Factory visualizationAchieve visualization of the performance data accumulated in manufacturing according to the respective positions of control, management, and workplace.

Factory visualizationAchieve visualization of the performance data accumulated in manufacturing according to the respective positions of control, management, and workplace.

This will not only confirm the progress at the site, but also lead to improvement activities and analysis.

TraceabilityFor customers in the heavy industry and engineering industries, manufacturing management is required from order receipt to design, manufacturing and performance.

TraceabilityFor customers in the heavy industry and engineering industries, manufacturing management is required from order receipt to design, manufacturing and performance.

In addition, in the manufacturing process, various measures such as design of blade, design changes, process defects and rework are required.

Even in such a complex manufacturing environment, product serial verification (tracing) of safety, functionality, and effectiveness is achieved by ensured quality from design to production/manufacturing.Manufacturing execution management sophistication Offering Details

Manufacturing digital transformation (DX) theme and solution system to realize management innovation

Introduction to our manufacturing digital transformation offerings by theme

Planning Sophistication Offering

Offering

Products Page

- FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES Innovative Case Study Report on Production Planning Operations in the Global Supply Chain GLOVIA smart PROFOURS (PDF)

- Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES (YouTube)

- Tohshin Seiki Co.,Ltd. (PDF)

- RISU PACK CO., LTD. (PDF)

- GOLD PAK CO., LTD. (PDF)

- Fujitsu Limited (PDF)

- List of introductory materials on Planning Sophistication Offering

Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES

Successful application of "PROFOURS" in FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES Fujitsu Manufacturing DX journey to the best

Fujitsu Manufacturing DX journey to the best An Integrated Planning and Management Solution “PROFOURS” : A reliable field partner

An Integrated Planning and Management Solution “PROFOURS” : A reliable field partner GLOVIA smart PROFOURS - Integrated production planning system for improving work efficiency

GLOVIA smart PROFOURS - Integrated production planning system for improving work efficiency

- Under Construction

Upgradation of cost and production Offering

production Offering

Products Page

- Upgradation of cost Offering

- Fujitsu Application for SAP® Solutions Actual Costs Template

- Fujitsu ERP Solutions for Process

(Old name : FUJITSU Enterprise Application GLOVIA ProcessC1)

- Upgradation of production Offering

- List of introductory materials on Upgradation of cost Offering

- List of introductory materials on Upgradation of production Offering

Fujitsu best add-in solution for flexible use of SAP

Fujitsu best add-in solution for flexible use of SAP

Fujitsu Application for SAP® Solutions

Mass Customization Template

An ERP solution for Assembly Manufacturers Realize Mass Customization through Product Configuration Management

An ERP solution for Assembly Manufacturers Realize Mass Customization through Product Configuration Management

Fujitsu Application for SAP® Solutions

Mass Customization Template (SIEMENS)

Provided by Fujitsu

Provided by Fujitsu

SAP Engineering Manufacturing Execution Solution

SAP S/4HANA® Manufacturing for Production Engineering and Operations

Solutions to manage all multiple parallel planning, development, and investment projects

Solutions to manage all multiple parallel planning, development, and investment projects

SAP® Portfolio and Project Management

Fujitsu’s SAP Manufacturing Solutions

Fujitsu’s SAP Manufacturing Solutions

Fujitsu Manufacturing DX journey to the best

Fujitsu Manufacturing DX journey to the best Fujitsu Application for SAP Solutions makes mass customization for manufacturing possible

Fujitsu Application for SAP Solutions makes mass customization for manufacturing possible Fujitsu Application for SAP® Solutions Mass Customization Template

Fujitsu Application for SAP® Solutions Mass Customization Template

~Product Concept Version~ Fujitsu Application for SAP® Solutions Mass Customization Template

Fujitsu Application for SAP® Solutions Mass Customization Template

~Quotation Version~ Fujitsu Application for SAP® Solutions Mass Customization Template

Fujitsu Application for SAP® Solutions Mass Customization Template

~Order Navigator Version~ Fujitsu Transforming the future of manufacturing

Fujitsu Transforming the future of manufacturing

Manufacturing execution management sophistication Offering

management sophistication

Offering

Products Page

- List of introductory materials on Upgradation of production Offering

Manufacturing cluster that realizes manufacturing DX

Manufacturing cluster that realizes manufacturing DX

Provided by Fujitsu

Provided by Fujitsu

SAP Manufacturing Execution System (MES)

Provided by Fujitsu

Provided by Fujitsu

SAP Cloud Manufacturing Solutions (SAP DMC)

SAP DMC Achieving DX Manufacturing beginning from a Small Start

SAP DMC Achieving DX Manufacturing beginning from a Small Start

Provided by Fujitsu

Provided by Fujitsu

SAP Engineering Manufacturing Execution Solution

Fujitsu Manufacturing DX journey to the best

Fujitsu Manufacturing DX journey to the best How to keep manufacturing operations compliant

How to keep manufacturing operations compliant Smart Manufacturing Customer References with COLMINA and SAP Offerings ”Collaboration with SEMENS”

Smart Manufacturing Customer References with COLMINA and SAP Offerings ”Collaboration with SEMENS” FNC uses Fujitsu SAP to build the factory of the future

FNC uses Fujitsu SAP to build the factory of the future Reimagine your business with Fujitsu and SAP : KAWASAKI case study

Reimagine your business with Fujitsu and SAP : KAWASAKI case study Transform your manufacturing to next generation with Fujitsu SAP Industry 4.0

Transform your manufacturing to next generation with Fujitsu SAP Industry 4.0 SAP MII Solution proposed by Fujitsu

SAP MII Solution proposed by Fujitsu

- Under Construction

What our customers say

Fujitsu’s Commitment to Manufacturing Digital Transformation (DX) – Efforts Related to the SDGs

As a Digital Transformation (DX) company, in April 2021, Fujitsu announced seven focus areas for accelerating growth together with our customers starting with social issues. One of these areas is Sustainable Manufacturing, where we propose to achieve recycling-oriented sustainable manufacturing. This concept of recycling-orientated and sustainable manufacturing is also aligned with the ecosystem approach to achieving the SDGs.

Fujitsu’s mission is to provide manufacturing solutions that address the uncertainty of the future and the diversity of needs.

Fujitsu’s capability to achieve manufacturing Digital Transformation (DX)

Based on our know-how and strengths as a member of the manufacturing industry with our own manufacturing DNA, Fujitsu contributes to its customers by leveraging its “manufacturing knowledge” in business areas where it has a wealth of references (business improvement of manufacturing sites).

Unique know-how as a manufacturing company

Over 20 manufacturing locations in Japan

Manufacturing (Design - Production - Performance)

In-house development of commercial applications

Sole vendor in Japan

Our experience in providing manufacturing solutions

Over 10,000 companies