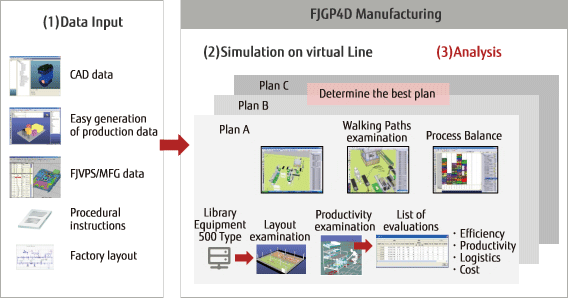

Manufacturing Solution FJGP4D automatically estimates production capacity from a process plan in order to obtain maximum performance

- Review of a new production line

- Making improvements in advance

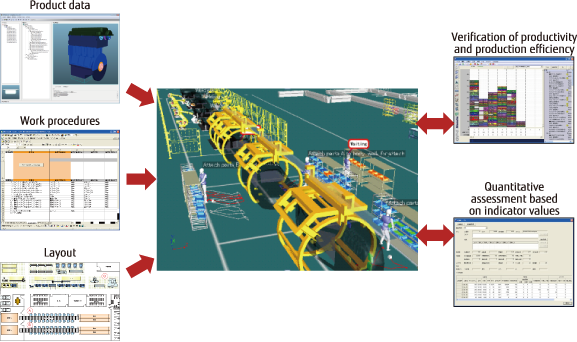

FJGP4D (semi-) automatically simulates the movements of persons and flows of materials.

- Predicts productivity, work efficiency, and costs

- Develops measures to prevent potential problems

FJGP4D key benefits

FJGP4D is a powerful production support tool for visualizing process design. We support effective process design and various kinds of evaluation in the field of assembly and logistics.

Customer Benefits

- Launch global mass production efficiently and reduce costs.

- Plan without running actual trials. Calculate productivity quantitatively. Determine the best plan theoretically.

- Realize "KAIZEN" and high productivity without stopping the current line.

FJGP4D to Improve Manufacturing Process Planning

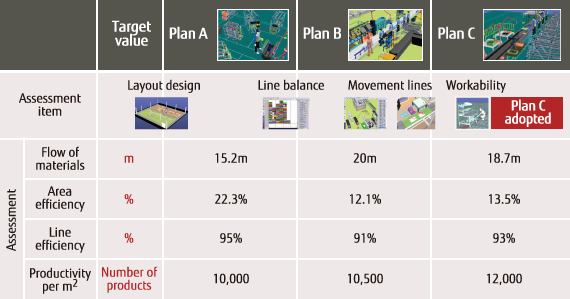

- FJGP4D develops multiple models for 3D line plans made during the planning stage.

- The software can be used to assess layout designs, line balance, movement lines, and workability, as well as whether production indicators achieve target values- all without creating actual production lines.

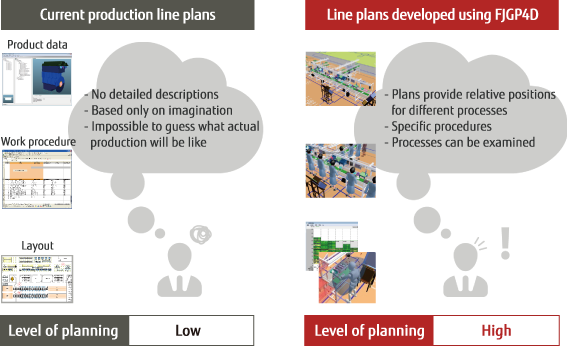

Problems with Process Planning, ICT Solutions

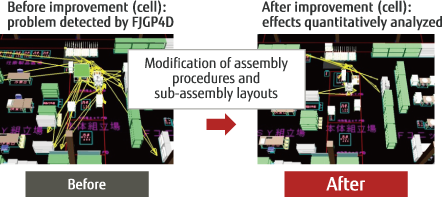

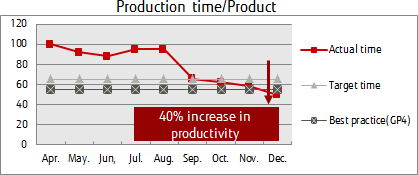

FJGP4D case study

Company A

Challenge:

- Due to rapid changes in production resulting from external causes, it was difficult to match operators' skill levels with work levels.

Effects:

- Walking distance: Reduced 43%

- Value of in-process items in stock: Reduced by 20-30%

- Productivity: Increased 40%

| Before | After | |

|---|---|---|

| Walking distance | 174.1 m | 133.5 m |

| Cycle time

| 55 min. | 39.6 min. |

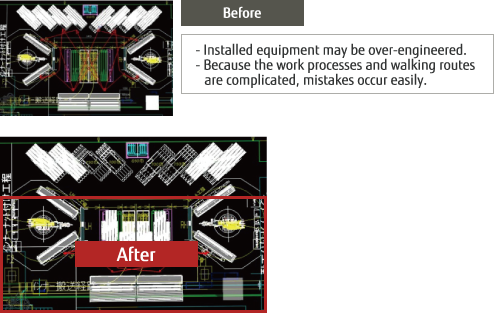

Company B

Issue :

- Use of the 2D tool-based process design does not allow enough time for an examination to be performed during the production preparation period.

Effects:

- FJGP4D makes it possible to reduce the examination time by 50% and to increase the efficiency of the process design for the heavy load process.

- By implementing KAIZEN activities before the start of mass production, the number of scheduled workers was able to be reduced by 50%.

| Cycle Time | NET Time | Accompany | NET Rate | Walk | Capacity Utilization | |

|---|---|---|---|---|---|---|

| Plan A

(current) | 248.6s | 160s | 88.6s | 64% | 66M | 83% |

| Plan B

(KAIZEN) | 226.8s | 160s | 64.8s | 71% | 42M | 92% |

| Effect | Reduction of 21.8s | 0s | Reduction of 23.8s | Increase of 7% | Reduction to 24M | Increase of 9% |

FJGP4D product requirements

Use this information to ensure you are always work with FJGP4D supported and optimized system for hardware and operating system software.

| Recommended specifications | |

|---|---|

| Operating System | Microsoft Windows 10 (Pro, Enterprise)

Microsoft Windows8.1(Pro,Enterprise) Microsoft Windows 7 (Professional, Enterprise, Ultimate) SP1 *1 |

| CPU | 1GHz and above *2 |

| Physical memory (RAM) | 2GB and above (4 GB and above is recommended) *2 |

| Hard disk capacity | 1GB and above |

| Graphics card | memory 128MB and above

OpenGL compatible *3 Display resolution: 1280 x 768 pixels or higher |

| Software | Microsoft Excel is required for document output. *4

.NET Framework4.5.2 is required. (For Windows 7 or earlier) |

*1 The Aero is not supported. Aero is turned off automatically during operation of GP4VMS.

*2 The published values, and so on are minimum configration and the comfort of operating environment depends on such as data size of 3D model to handle.

When you select hardware, please confirm an operation in advance.

*3 According to the combination of a graphics card and a driver, the system might not work normally.

That case might be improved by updating the driver or adjusting the performance level of the hardware accelerator.

*4 Microsoft Excel 2016 32bits, Microsoft Excel 2013 32bits or Microsoft Excel 2010 32bits is necessary.