Five Megatrends of Digital Transformation in Manufacturing

How do you incorporate voice of customers to design customer-oriented manufacturing process?

Until the turn of the century, the manufacturing industry generally focused on developing, mass-producing and unilaterally delivering products. However, the Internet gave customers access to significantly more information about products and wider choices of them. This change led manufacturers, including those engaged in B2B, to incorporate customer feedback more proactively into their product development processes.

We believe manufacturers need to seriously consider building end-to-end digitalized operations and integrating internal and external processes across industries to provide rapid response to changing customer demands in these days.

Moreover, the COVID-19 pandemic has threatened both health and economies throughout the world. It has also exposed weaknesses in existing manufacturing operations and manufacturers faced huge challenge in continuity of normal business operations.

Digitalization is now key to creating resilient manufacturing systems that allow manufacturers to react in an uncertain future.

In this page Fujitsu introduces five megatrends and digital transformation in manufacturing as your digital transformation partner.

Fujitsu's vision for the future of manufacturing

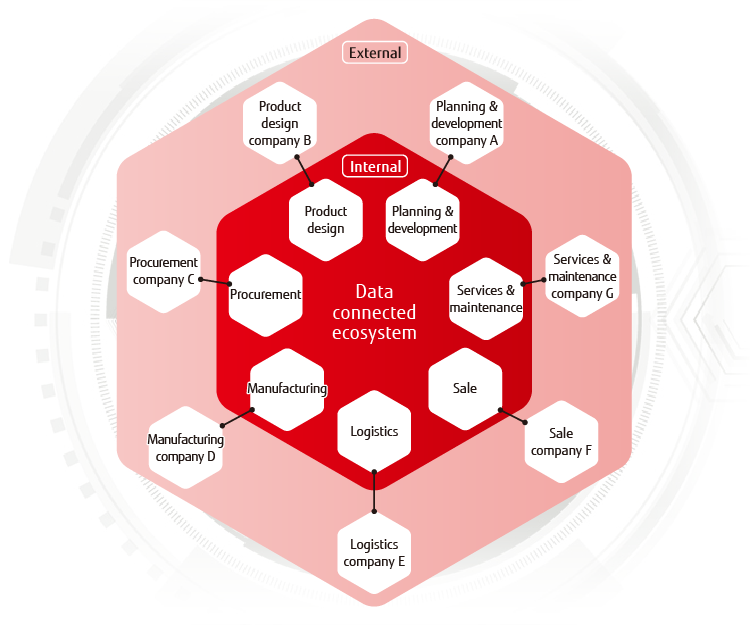

No single organization will be able to deliver all the value that customers want. The required value will be created only when suppliers, channel partners and other customer touch points become connected ecosystems. It is not enough to digitalize internal processes and link them with data.

Moreover COVID-19 has highlighted the need to rebuild more distributed supply chains with closer proximity to the market, in order to provide resilience against similar crises in the future.

We expect this approach will eventually enable manufacturing processes to work as integrated systems, delivering fully customized value in a timely manner. It is becoming a business priority for manufacturing companies to actively participate in such data-driven ecosystems, in order to exploit the potential of future manufacturing.

Five Mega Trends in Manufacturing

How will manufacturing change in the future? Fujitsu has identified five key factors that have huge impact on the industry’s future.

Fujitsu will create a sustainable future together with our customers by providing consulting services and platforms through digital transformation and by engaging in environmentally conscious activities. For details, see "Digital Transformation in Manufacturing".