Smart Manufacturing

Digitalization in manufacturing – the rise of the smart factory

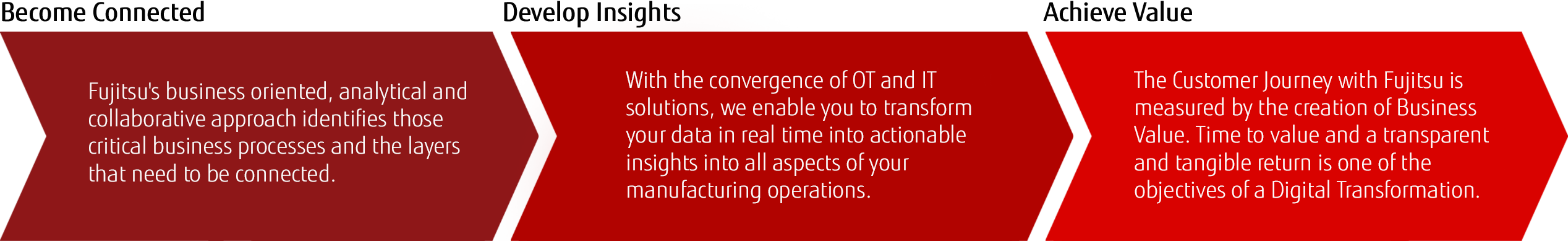

Fujitsu offers manufacturers an accelerated and innovative path to tangible and valiated business value utilizing Fujitsu's proven Digital Disruption methodology. We not only increase the time to value by digitally transforming manufacturing processes and operations with our methodology but more importantly Fujitsu maps and verifies the business value on your customized digital journey.

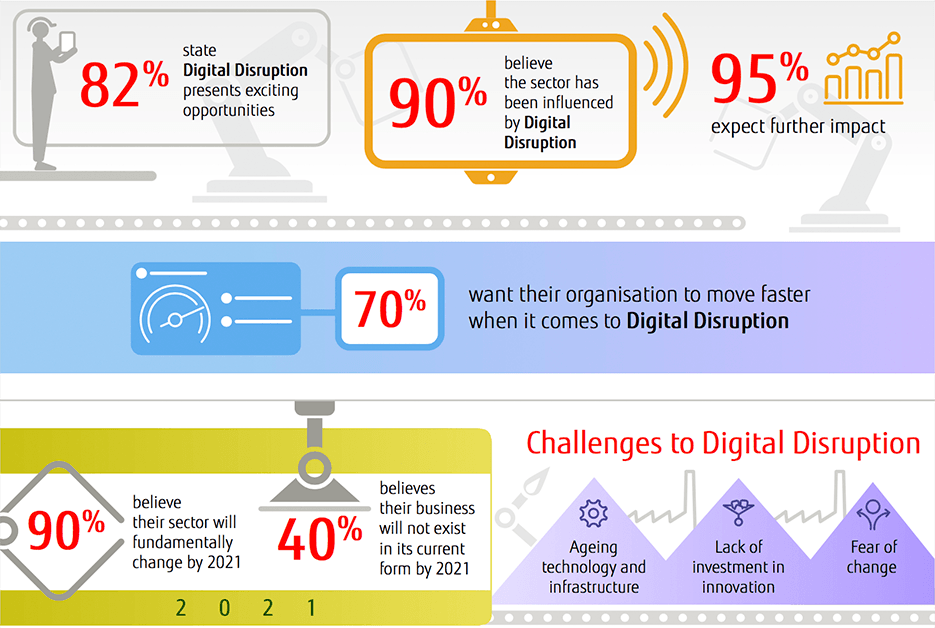

The Digital Disruption process can be exciting as well as challenging. While 82%* of manufacturing decision makers believe that digital disruption offers opportunities to keep pace with change, improve efficiency, increase productivity and reduce cost, far too many are concerned with the perceived complexity associated with Digital Disruption. Fujitsu's Digital Disruption methodology has as its foundation 4 Pillars which enable an innovative, transparent and pragmatic approach to your Digital Disruption journey.

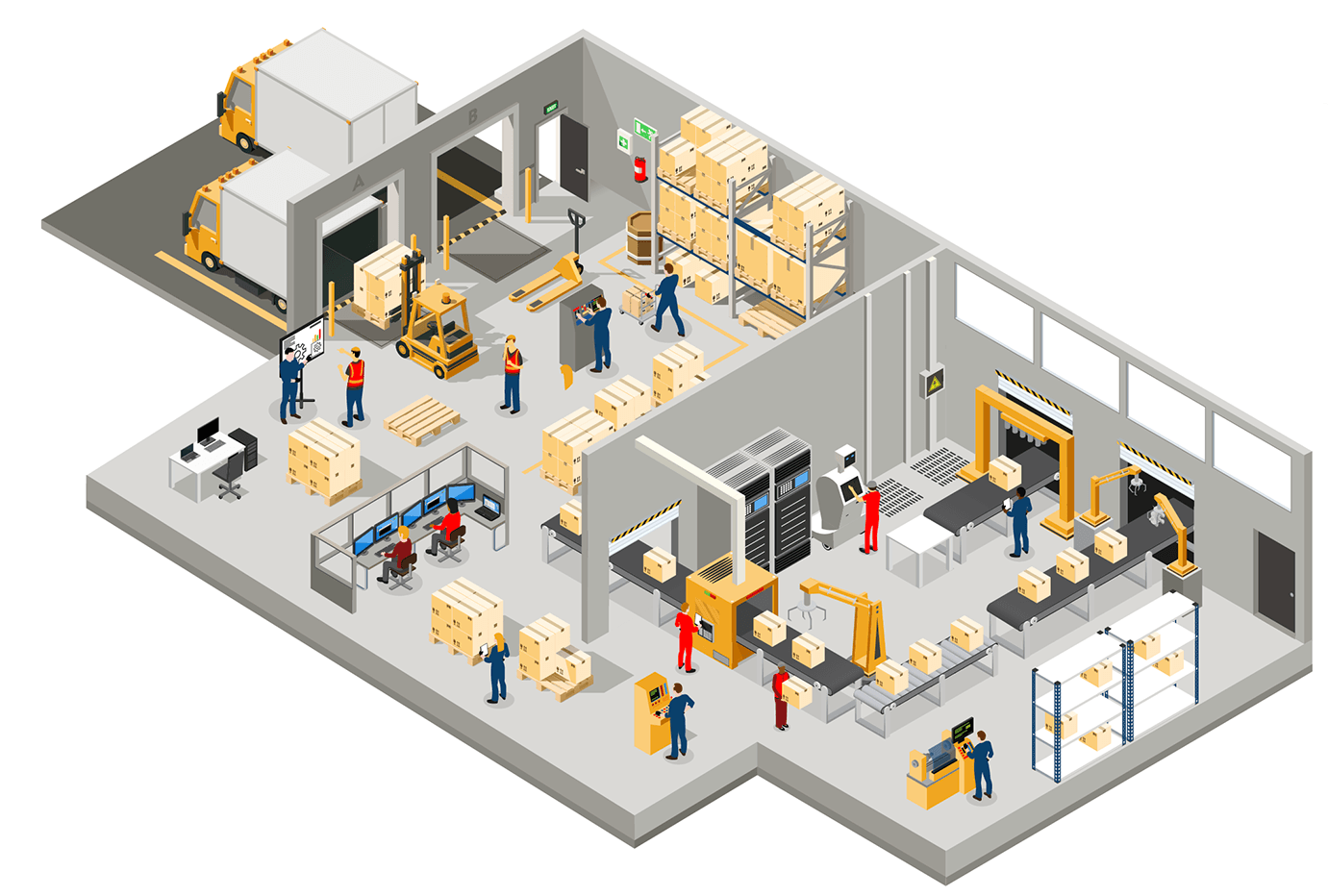

Smart Factory: Fujitsu's framework for creating the real time Operational Insight and Intelligence across the Manufacturing Domains designed to improve tactical and strategic operations and achieve tangible value.

How Digital applies to Manufacturing Process Automation and Connected Technologies

Fujitsu, as a world class manufacturer, is in a unique position to help you to harness the power of the connected and intelligent enterprise to create a highly optimized, lean manufacturing operation. Fujitsu has at the core of its' Digital Strategy, 3 critical attributes which become the foundation for a truly Digital Manufacturing Enterprise. The 3 attributes are: 1) Connected 2) Real Time and 3) Intelligent. Consider the following: Innovative and Intelligent IOT solutions seamlessly connect operational technology (OT) and IT to enable business critical smart processes utilizing data and analytics in real time to lower costs and increase operational effectiveness. The combination of ""Intelligent"", ""Real Time"", and ""Connected"" applied to the Enterprise impacts not just manufacturing but all lines of business from Sales, Human Resources Supply Chain, Finance that can be aligned to improve efficiency and performance. Fujitsu offers Intelligent solutions that connect at all levels of the Enterprise:

Fujitsu Industry 4.0 Use Cases

Shop Floor Visibility and Control of Demand Driven Manufacturing

Standardized MES for shop floor control and manufacturing visibility of 10 fabrication site, 9 manufacturing sites and 9 repair centers which complete 40,000 custom, configurable orders/day.

Solutions: SAP ME, SAP MII, SAP PCO, WebSockets, KepWare and OPC DA/UA interface

Human-Robot Collaboration

At Fujitsu’s Digital Smart Factory in Augsburg, Germany, robots assembling highly sensitive computer mainboards work hand-in-hand with their human colleagues

Solutions:Fujitsu, Kuka, SAP ECC

Industry 4.0 Demonstration Showcase

Self-contained robotics demo, highlighting various manufacturing scenarios

Solutions:SAP ME, SAP MII, SAP DMC, SAP Analytics Cloud IOTA Distributed Ledger, Fujitsu INTELLIDGE devices

Realtime Visualization of Production Flow

Enables non-experienced workers to analyze each circuit board’s production status, analyzing the root cause, leading to a six times gain in problem tracking and production improvement.

Solutions:Fujitsu IP

Automated Turbine Blade Inspection

Fujitsu and Siemens co-created an Artificial Intelligence (AI) solution that automatically detected flaws through machine learning and deep learning capabilities

Solutions:Fujitsu Advanced Image Recognition (F/AIR)

High Tech Production Visibility

SAP Manufacturing Execution helped FUJIFILM Dimatix increase visibility across the organization, reduce Process errors, and minimize product recall exposure during a period of rapid sales growth while lowering WIP and inventory levels.

Solutions:SAP ME, SAP MII, SAP PCO, SAP ECC 6.0

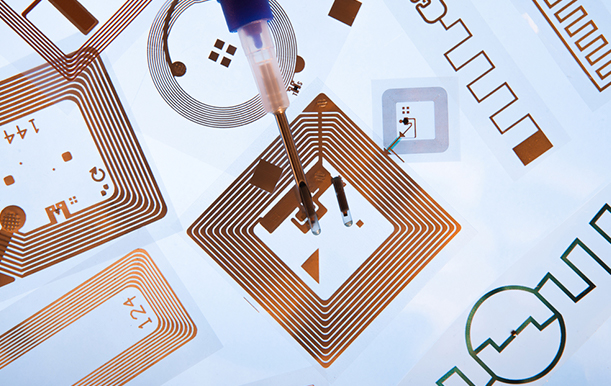

Bourbon Barrel Tracking

RFID monitoring of the production, storage and distribution of millions of bourbon barrels

Solutions:Fujitsu GlobeRanger RFID

Smart Factory Sales Play

Meet our manufacturing experts

Paul Bresnahan

Head of Manufacturing Industry

paul.bresnahan@fujitsu.com

Greg Pincar

Senior Management Consulting Director

greg.pincar@fujitsu.com

Alok Sahu

Head of Innovation as Service

alok.sahu@fujitsu.com

Rahman Mahbub

Asia

Mahbub.Rahman@fujitsu.com

Michael Straub

Europe

Michael.Straub@fujitsu.com

Find out more about our digital IT solutions for manufacturing

Manufacturing Optimization

With our help you can increase efficiency, view processes, address bottlenecks in real-time, reduce inventory and increase throughput. Our comprehensive offering includes; AI Machine Learning, Predictive Maintenance, Data Analytics, Intelligent Dashboard.

Augmented Reality / Head Mounted Device

Our range of devices use sensors to detect a user’s environment and behavior to enable you to tailor the delivery of remote support, help with maintenance and worker training.

Wearables - worker safety

Using the Fujitsu Ubiquitousware range, you can better manage workforce safety. Workers are monitored in their surroundings and the real-time biometric data collected is used to gain insight into working conditions that can help you to deliver safety improvements.

RFID and Globeranger

Our GlobeRanger range of solutions enable end-to-end traceability in the supply chain. We ensure supply chain efficiency, traceability and security right from goods in through to customer delivery.

Cyber Security

Working in partnership with world-leading security vendors including; Symantec, Log Rhythm, Forcepoint, McAffee, becrypt, Proofpoint, Juniper and Check Point we keep your systems, processes and customer data safe.

F|AIR FUJITSU Advanced Image Recognition

Dependency on skilled workers for visual inspection across quality control adds significant cost to production, risks product quality and reputational damage due to potential of human error. Fujitsu has proven how Artificial Intelligence (AI) can be applied to help organizations respond to these challenges.

-

Omron, Japan: We developed a system for electronics manufacturer Omron to produce a ‘ Manufacturing line operations visualisation’ report

Omron, Japan: We developed a system for electronics manufacturer Omron to produce a ‘ Manufacturing line operations visualisation’ report

-

INESA, China: For INESA we implemented IOT and Big Data technology, to solve the problem of real-time information lag

INESA, China: For INESA we implemented IOT and Big Data technology, to solve the problem of real-time information lag

-

Airbus, France: We helped Airbus to digitalise its operations with RFID technology deployed across the full life cycle of its operations

Airbus, France: We helped Airbus to digitalise its operations with RFID technology deployed across the full life cycle of its operations

Co-creation for success:

Unlocking creativity, knowledge and innovation

Manufacturing research results

The world has transformed dramatically in recent years with organizations across all sectors feeling the effects of this change. Manufacturing organizations are required to serve and positively impact three core audiences: their employees, customers and, increasingly, citizens and wider society. Manufacturing business leaders prioritize employees above all else but know that, to ensure sustained success, they must find a way of delivering for all audiences – a challenge they believe can be met by creating relationships with customers, unleashing creativity across the business and utilizing the full power of digital technology.

Learn why almost 60% of manufacturing leaders admit it is difficult to balance the expectations of all three audiences.Read More

Co-creating the digital factory

Manufacturers have pioneered the use of sensors and data-based monitoring, but today real-time controls and machine intelligence are taking the sector to a new level of productivity. It is becoming a hyperconnected industry. Explore our digital factory to find out more.

Download infographic