Digitalisation in manufacturing – the rise of the smart factory

Today, manufacturers are under intense pressure to adopt the next generation of smart technology to keep pace with change, improve efficiency, increase productivity and reduce cost. With so many challenges to overcome - increased market competition, rising customer demand for innovative new products at lower cost, security threats and workforce concerns such as improving human-to-machine interaction, manufacturers must digitally transform their processes and operations.

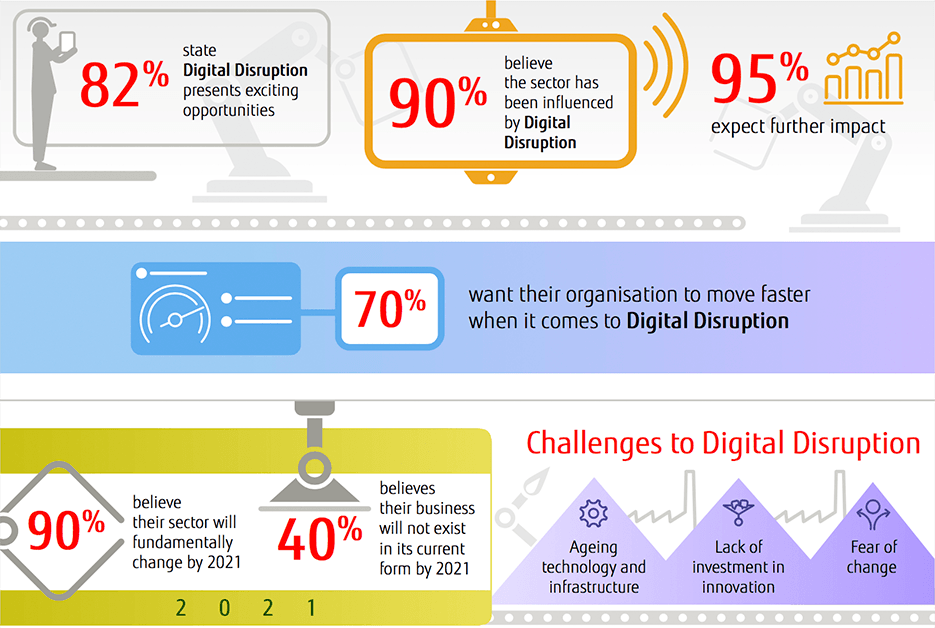

However, whilst 82%* of manufacturing decision makers believe that digital disruption offers many exciting new opportunities, far too many are failing to implement the digital solutions needed to increase connectivity, get closer to customers and build new service-centric business models. Manufacturers’ continued reliance on unwieldy and complex legacy IT systems and infrastructure greatly reduces their ability to thrive in the new digital world and take advantage of the opportunities digital disruption brings. Those failing to adapt to change and implement the right digital manufacturing solutions will, therefore, lose out to those competitors who do.

*Source - Fujitsu Fit for Digital: Co-creation in the Age of Disruption

Replay our Workplace 2025 Webinar

Workplace 2025 for manufacturing - the essential guide to building a future-proof workplace. Is your business ready for how the world of work will dramatically change over the next decade? Playback this webinar to see experts from Fujitsu and industry analyst group CXP, discuss tackling the shifting sands of the future workplace in Manufacturing.

Replay our Manufacturing ServiceNow Webinar

In this webinar we shared how Fujitsu has helped global manufacturing organizations to deliver business services faster, better and smarter, through ServiceNow. ServiceNow represents a critical element in the delivery of smart manufacturing and the running of the digital factory. The flow of goods, data, and ideas needs a strong foundation, and that’s what the solution delivers.

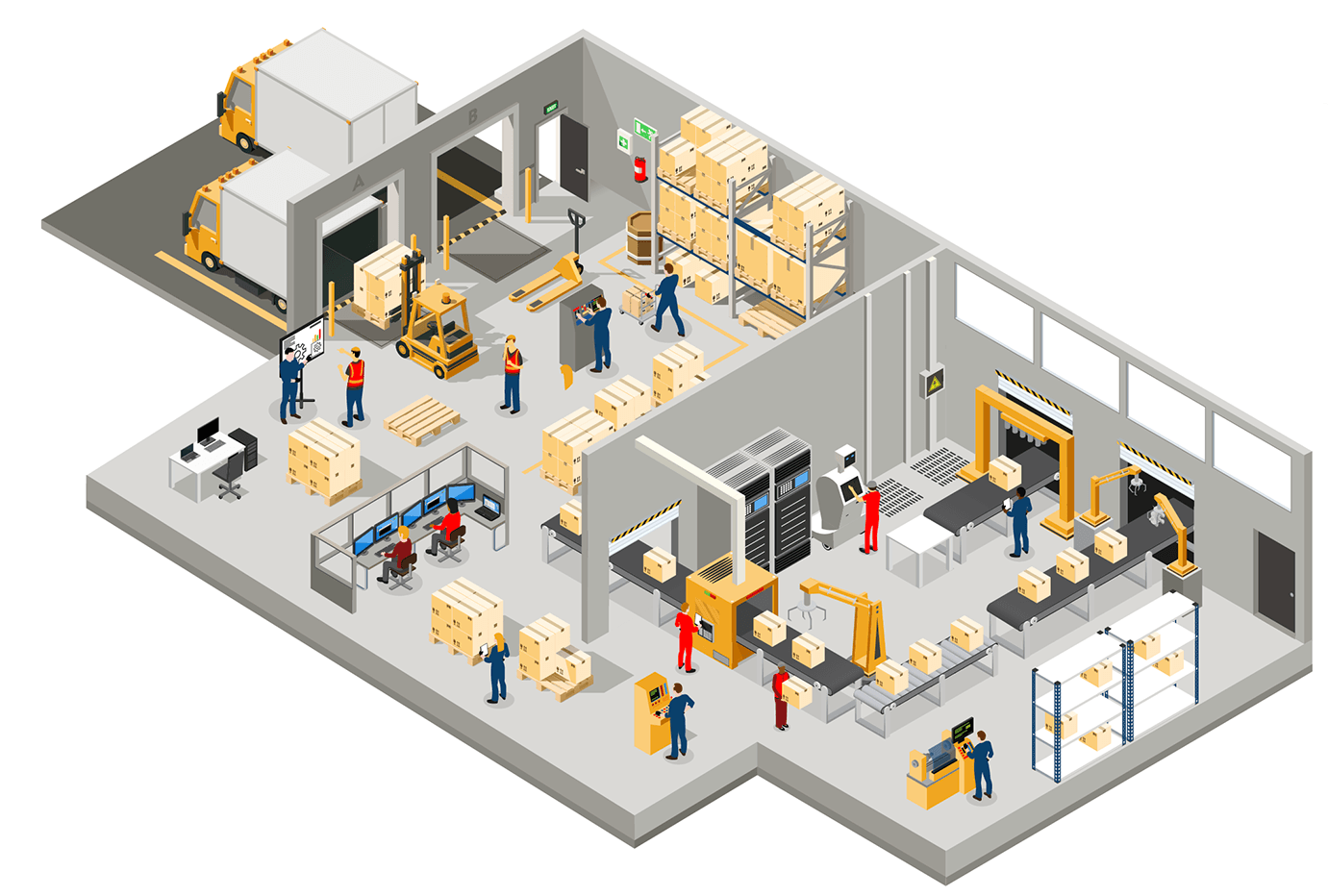

Manufacturing process automation and connected technologies

Within the smart factory, traditional physical processes are integrated with cutting-edge IT to connect people, networks and things. Innovative IoT solutions seamlessly connect operational technology (OT) and IT to enable smart processes that utilise the power of data analytics to lower costs and increase operational effectiveness. All lines of business from sales, customer service and HR, to supply chain, finance and R&D, can be digitalised to improve efficiency and performance.

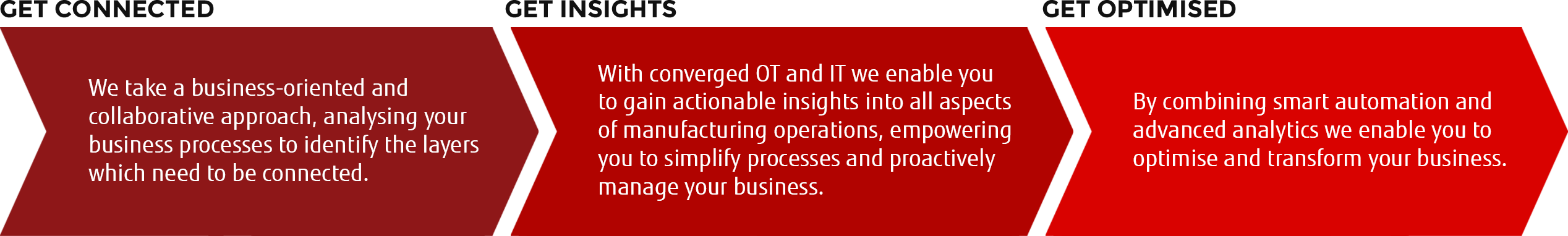

Fujitsu Connected Enterprise

As both an IT solutions provider and world-class manufacturer with over 50 years of experience, Fujitsu is in a unique position to help you to harness the power of the connected enterprise and create a highly optimised, lean manufacturing operation. We deliver a full set of manufacturing IT services that underpin the requirements of digitalisation. Our solutions leverage the convergence of IT and OT to enable smart, connected operations. Through the implementation of mobility technology, data analytics and industrial machine-to-machine connectivity, we enable you to gain insight and understanding from the vast amount of operational data you generate every day. With our help, you can transform your processes and proactively manage all aspects of your operation, live and in real time.

Fujitsu Connected Assets

Our sensor connected devices enable you to gain better visibility into asset availability, performance and maintenance processes. Using the real-time data generated, your maintenance teams can assess the health of critical components in systems, facilities and machines, as well as automate maintenance processes based on asset health indexes. Our connected solutions deliver real-time asset monitoring and condition-based predictive maintenance to unlock the full potential of your asset investment.

Fujitsu Connected Workers

We connect people and processes in a secure way. Through real-time sensing of employee environment, location, motion, and vital signs your workers’ health and safety can be significantly improved. In addition, Augmented Reality enables maintenance technicians to increase productivity as quality inspections and installations can be guided remotely.

Find out more about our digital IT solutions for manufacturing

Manufacturing Optimisation

With our help you can increase efficiency, view processes, address bottlenecks in real-time, reduce inventory and increase throughput. Our comprehensive offering includes; AI Machine Learning, Predictive Maintenance, Data Analytics, Intelligent Dashboard.

RPA

With Fujitsu Robotic Process Automation your organisation can increase operational efficiency, reduce human error, improve customer experience, deliver productivity improvements and minimise cost.

Augmented Reality / Head Mounted Device

Our range of devices use sensors to detect a user’s environment and behaviour to enable you to tailor the delivery of remote support, help with maintenance and worker training.

Wearables - worker safety

Using the Fujitsu Ubiquitousware range, you can better manage workforce safety. Workers are monitored in their surroundings and the real-time biometric data collected is used to gain insight into working conditions that can help you to deliver safety improvements.

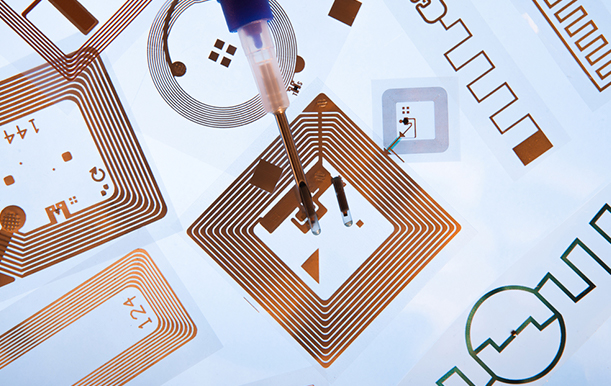

RFID and Globeranger

Our GlobeRanger range of solutions enable end-to-end traceability in the supply chain. We ensure supply chain efficiency, traceability and security right from goods in through to customer delivery.

Cyber Security

Working in partnership with world-leading security vendors including; Symantec, Log Rhythm, Forcepoint, McAffee, becrypt, Proofpoint, Juniper and Check Point we keep your systems, processes and customer data safe.

RunMyProcess

With our digital Platform-as-a-Service, RunMyProcess we help you to transform the way your business works. We deliver end-to-end digital systems that connect people, software and things.

See how our customer solved their challenges

British American Tobacco, UK

We supported the migration to Windows 10 for BAT’s 36,000 users worldwide. Using our global service desk capabilities, specialist staff and self-service portal we completed the upgrade at a 10th of BAT’s previous upgrade cost. Benefits – annual £10m saving via user self-service.

Read More

-

Omron, Japan: We developed a system for electronics manufacturer Omron to produce a ‘ Manufacturing line operations visualisation’ report

Omron, Japan: We developed a system for electronics manufacturer Omron to produce a ‘ Manufacturing line operations visualisation’ report

-

INESA, China: For INESA we implemented IOT and Big Data technology, to solve the problem of real-time information lag

INESA, China: For INESA we implemented IOT and Big Data technology, to solve the problem of real-time information lag

-

Airbus, France: We helped Airbus to digitalise its operations with RFID technology deployed across the full life cycle of its operations

Airbus, France: We helped Airbus to digitalise its operations with RFID technology deployed across the full life cycle of its operations

Co-creating the digital factory

Manufacturers have pioneered the use of sensors and data-based monitoring, but today real-time controls and machine intelligence are taking the sector to a new level of productivity. It is becoming a hyperconnected industry. Explore our digital factory to find out more.

Download infographic