Fujitsu Decision Making Optimization

Optimizing and strengthening the value chain through data-driven decision-making

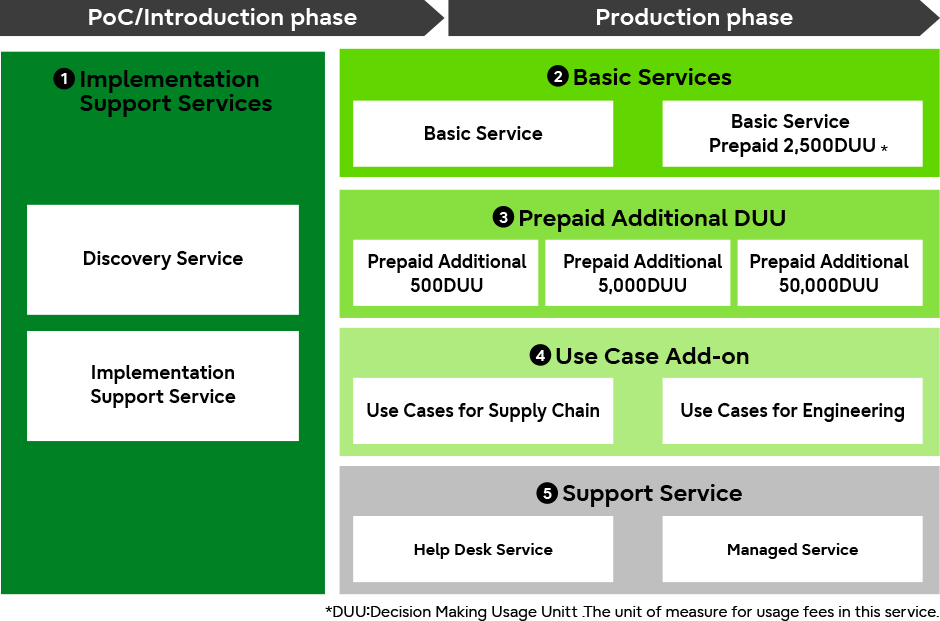

"Fujitsu Decision Making Optimization" is a service that optimizes and strengthens value chains through rapid, data-driven decision-making. By linking data from each value chain end-to-end (E2E), "Fujitsu Decision Making Optimization" enables quick identification of the impact on ECM *1 /SCM *2 and supports informed decision-making for product supply to the market.

- *1:Supply Chain Management:A method for managing upstream processes in manufacturing.

- *2:Engineering Chain Management:A management method that optimizes the entire production and distribution process from raw materials to consumers.

Serveice Overview

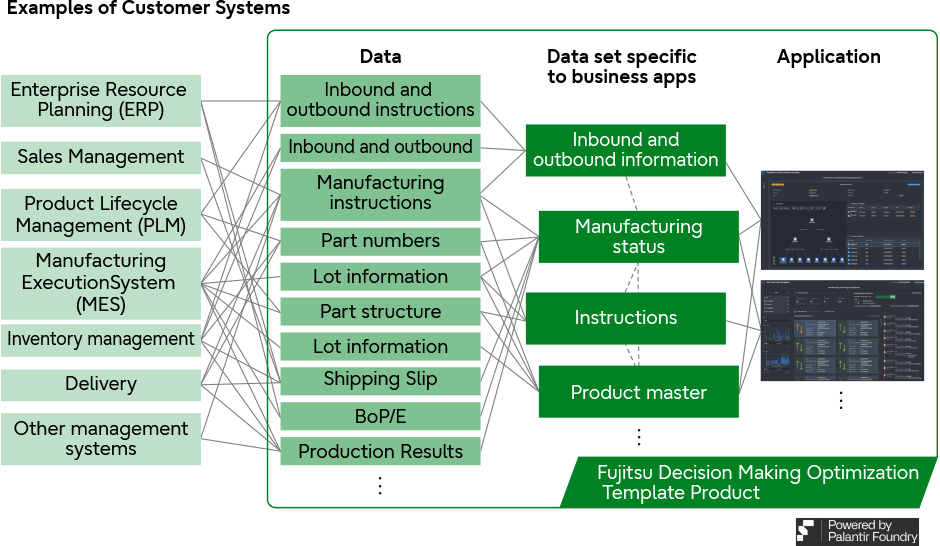

In addition to traditional QCD, the manufacturing industry is required to address various issues such as innovation, environmental friendliness, safety, and supply chain transparency. Especially in the ECM and SCM domains, data utilization is on the rise. While the use of data is increasing in the ECM and SCM areas in particular, manual data verification and manual data linkage between systems are still occurring, and there is a need to break free from the dependency on human resources and speed up decision making."Fujitsu Decision Making Optimization" is a service that integrates data from the ECM and SCM domains and provides use case-based applications to support customer decision-making aligned with their specific business operations." This enables quick and data-driven operations and eliminates the pains faced by management and front-line workers, such as QCD improvement, labor shortages, and human resources.

Key Benefits

-

- Rich Manufacturing Exterpise to accelerate DX with a data model

- Horizontal deployment of data models and use cases that have been cultivated over many years in the manufacturing industry and have proven results in our own and other companies.

-

- Experienced engineering support structure

- Data utilization engineers with extensive practical experience will propose the best approach and optimal solutions based on the issue.

-

- Innovation across the value chain

- By combining multiple use cases, it is possible to accelerate digital transformation across the entire company not only in terms of design, but also in terms of manufacturing and management, such as SCM.

Use Case

Fujitsu Decision Making Optimization provides two use cases : for Engineering and for Supply Chain.

Use Cases for Engineering

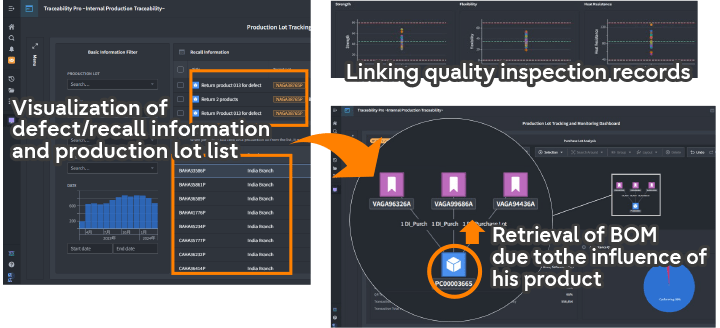

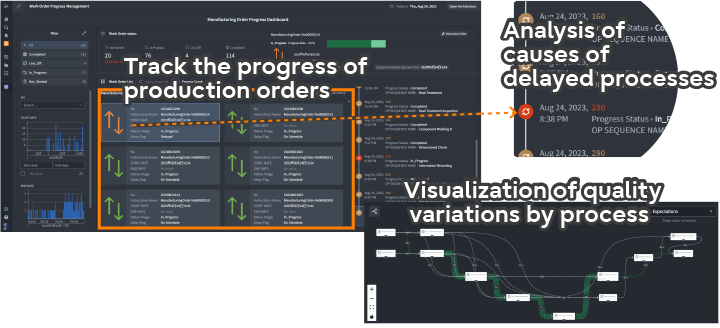

It offers use cases that address challenges in Engineering Chain Management, such as improving product quality, preventing fraud, ensuring supply chain transparency, and accelerating recall response.

-

[ Application example ]

-

- Challenge

-

- Data-driven management of operations related to design, procurement, and manufacturing

- Quality control, compliance enhancement, customer confidence, and quick response to recalls

-

- Results

-

- Prompt response to customers and management to ensure trust

- Quick response to recalls 70% reduction

- Reduction of a large number of man-hours without changing core systems 90% reduction

- Prevention of overtime work and creation of a pleasant workplace Zero overtime work

-

-

[ Screen images ]

Reverse lookup of all information in the event of defect/recall - For the Quality Assurance Department -

Manufacturing process monitoring/Manufacturing flow monitoring and improvement - For the Production Management Department -

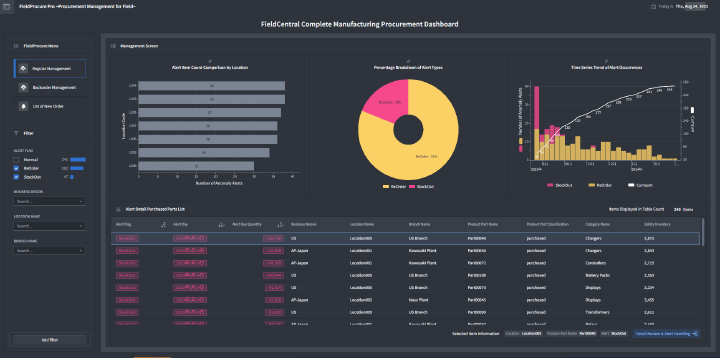

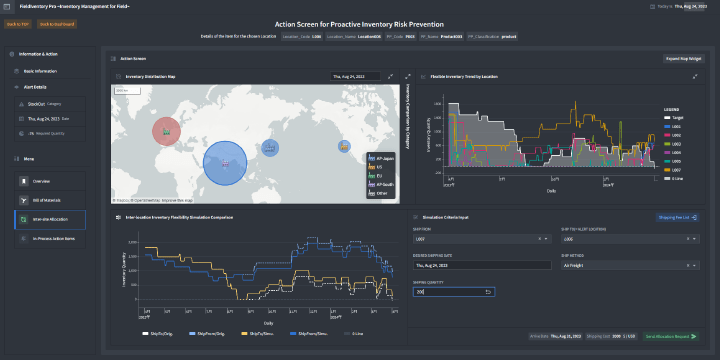

Use Cases for Supply Chain

It offers use cases that address SCM challenges like inventory management and supply chain resilience, empowering data-driven decision-making and business transformation across the organization.

-

[ Application example ]

-

- Challenge

-

- To consolidate transaction data such as “demand,” “production,” “inventory,” “orders,” and “order backlogs” for the entire business, and to enable lean inventory and order management throughout the entire company.

-

- Results

-

- Reduce costs by optimizing operational efficiency and adjusting inventory

- Maximize profit opportunities by reducing the risk of lost sales and production opportunities in the SC

- Reduce excesses and shortages by managing inventory to reflect the entire supply chain

-

-

[ Screen images ]

Alert management of reorders and shortages & list of account statements

Preliminary simulation & action execution of inventory flexibility among locations

Notice

-

April 25,2025Information

- This website has been launched.