Contractor management

Smart Factory Contractor Management System

A major challenge for plant managers is making sure that the contractors they hire are productive and stay safe while on the job.

But without a strong contractor management system, finding the right contractor for a project–whose workers have the proper skills and safety training–can be a headache.

Fujitsu’s contractor management system, or CMS, is a key part of its Smart Factory technologies to help factories move forward with digital transformation. It can help make sure the contractor performs the job as ordered, does not stray into restricted areas at the plant and submits an accurate bill for time and materials.

Fujitsu implemented a CMS for the Siam City Cement Co. in Thailand as part of its Smart Factory roll out with SCCC, completed last year.

The foundation of the CMS is a digital profile on each contractor, which includes the contractor’s general information, skills, training records and work history. This profile also syncs with a safety training records database for each contractor.

Integration with other software

The Fujitsu CMS is also integrated with SAP PM (plant maintenance) software through which maintenance jobs are managed and work orders are issued.

“The CMS will pull all outstanding maintenance orders for SAP and map them with the qualified contractors automatically, which saves time and cost for users to do manual mapping,” says Ms. Khong Sheau Yan, Head of DX Strategic Office, Fujitsu (Thailand) Co., Ltd. That particularly helps the plant handle large turnaround projects that might involve 1,000 to 2,000 contractors or workers, she says.

Tracking system

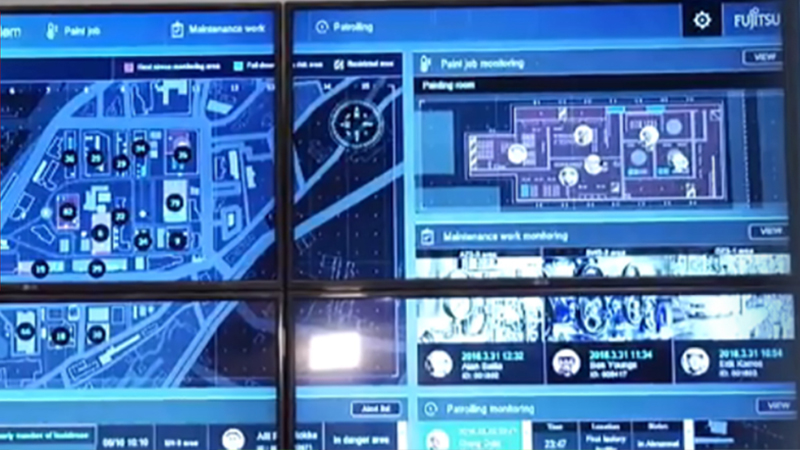

The CMS also is integrated with a real-time location system, RTLS, which can track contractors through use of tracking badges. The location of the contractors can be centrally monitored in the remote operation center, which is part of Fujitsu’s Smart Factory technologies implemented at the SCCC plant in Thailand.

The CMS implementation includes a system to ensure that contractors stay within their proper work areas and do not enter restricted areas where they do not belong.

“When a contractor enters the SCCC premises, they will be given a location tag with their profile downloaded to this tag,” says Khong. “In their profile that is integrated to the CMS system, the geo-fencing information is included. So when a contractor enters a place that he or she is not authorized to be, the tag will send an alert to the ROC (remote operation center) and local signage systems in order for the guard to pull them out.”

Employee safety and less downtime

Besides the CMS and real-time location system, Fujitsu can also provide a smart access control system, which can integrate with an air pollution control system to ensure employee safety in confined areas, she adds.

The CMS has real benefits for the bottom line, too, Fujitsu says. Location and behavior tracking (safety management), for example, is one area that can result in savings in such areas as reduced downtime caused by accidents and better morale for contactors and employees thanks to a safer workplace. That also can mean higher productivity and customer satisfaction, says Fujitsu.