Cyber Security for Operational Technology (OT)

Digitize your production with confidence

Manufacturing and utilities industries are striving to digitally secure their Operational Technology (hardware and software that control industrial equipment). Are the results up to requirements? With the rise of IT/OT convergence comes the added exposure to cyber attacks. Ensuring effective secure digital operations to maximize uptime and worker safety, to protect customer and business data and to avoid supply chain disruption is not a one off-challenge.

Proactively limiting the risk of OT networks is key to embracing the rapid pace of digital disruption. Our experts are committed to offering you a secure network that provides around the clock protection for your industrial processes and business critical assets.

Fujitsu collaborates with customers using these complementary services:

- OT assessment: Analyzing your existing networks, identifying gaps in compliance and standards (like NIS2 & NIST 2.0), establishing your risk profile and baselining your networked digital assets.

- OT network transformation: applying priority remediations to protect your OT networks.

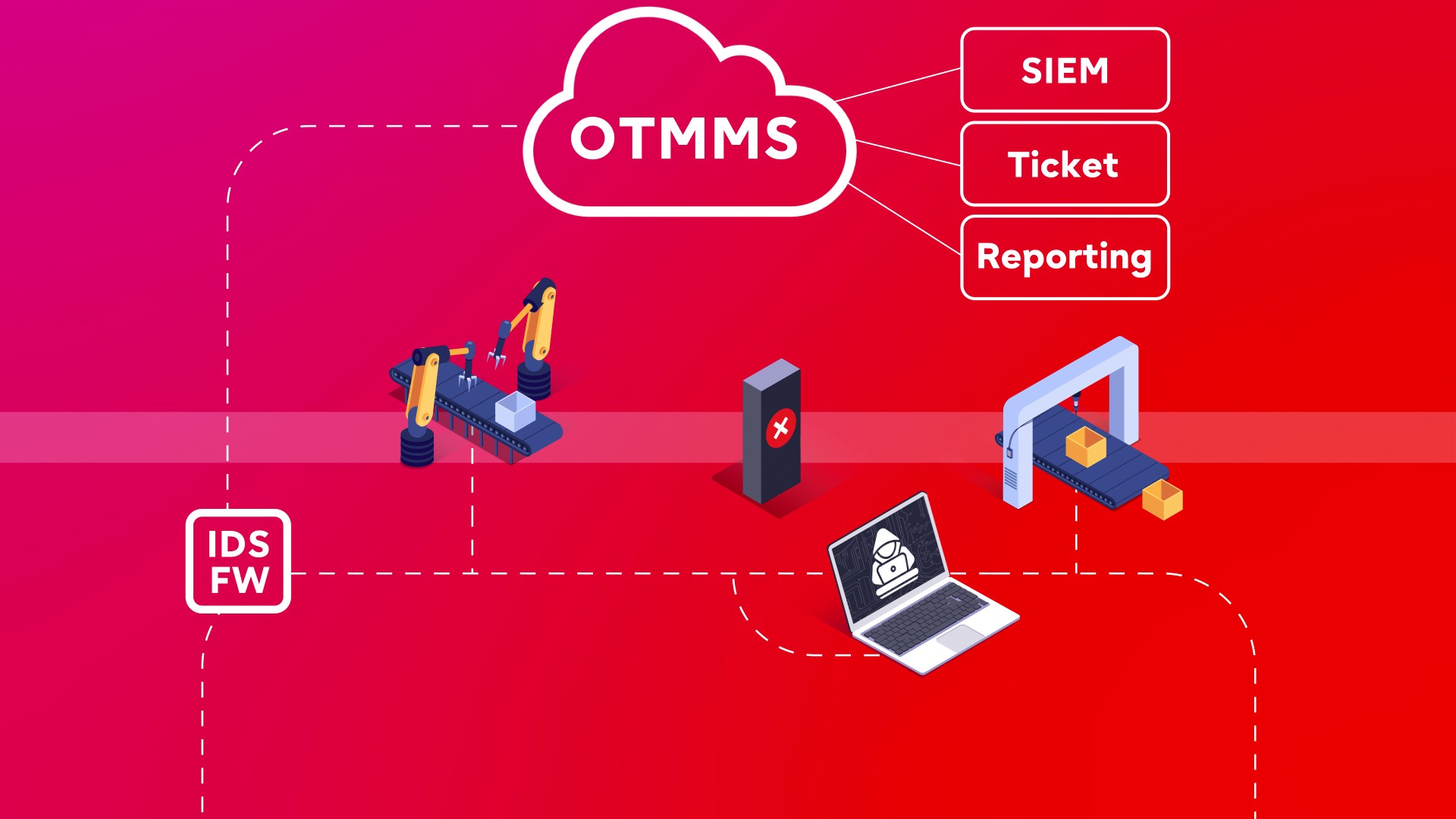

- OT managed monitoring service: a 24/7 service identifying anomalous behaviours across OT environments.

Expert videos

IDC interview paper with Jamie Wilkie

Read this exclusive interview from IDC Manufacturing Insights EMEA on OT security, how it is affecting your business and where and how your OT security journey can start.

See how Operational Technology is everywhere within manufacturing

Thought leadership perspectives: Why a strong OT security network is the key to digitalization and competitiveness

In the thought leadership paper we explain why and how you should secure your OT estate and integrate with your IT environment.

We also discuss the consequences of an ineffective OT security strategy against the benefits you can achieve when following the right approach. Fill out the form to explore how you can take your OT security to the next level.

Cyber security for OT

Explore how Fujitsu works to meet the unique security needs of your OT environment and which outcomes you can expect.

Quick self-assessment OT security

We offer you the opportunity to fill out a few basic questions on OT security to assess your cyber maturity in your production environment. It is free of charge and takes only a few minutes.

You will receive a first indication of how far you are on your OT security journey and some next steps suggestions.

Customer endorsement

"We cannot control what we cannot see. In the past, our industrial control systems were air-gapped and isolated from more conventional networks. As the manufacturing industry is becoming increasingly digitized, we also had the challenge of greater connectivity and convergence between IT and OT in order to remain competitive and relevant. We chose Fujitsu to do an OT assessment for RPM because of their experience within our industry. Their service is based on a proven methodology, supported by OT discovery and analysis technology, to give deep and actionable insights."

Mark Rankin, Vice President of Global Systems at RPM International Inc.

Podcast ‘The New World of Manufacturing’

Listen to the Peggy Smedley show of 15 minutes now

In this podcast you will find out about the IT and OT convergence in manufacturing and how how ecosystems are changing and manufacturers need to adapt. Our speakers: Jamie Wilkie, Product Owner OT Security Services and Sebastiaan Laurijsse, Global Head of Industry High Tech, ServiceNow.

Listen to the podcast now!

OT Security webcast: What's it like to be hacked?

Pilz and Fujitsu sharing best practices

In 2019, Pilz – an industrial automation safety company – was hacked. In this webcast of 17 minutes Jamie Wilkie (Product Owner OT Security Services at Fujitsu) and Hansjörg Sperling-Wohlgemuth (Manager Public Relations at Pilz), have a discussion on cyber security within manufacturing.

Pilz was hacked in a classical way via an email attachment and open VPN portal. Company employees could not work with their IT at all and production was completely lost for one week before it could gradually be resumed.

Hansjörg explains that the company decided in an early phase not to pay any money to the hackers! Due to the good team and agile approach, Pilz actually managed to deliver the first parts after a week, but the full process of recovery was a tough journey. Working with zones has turned out to be one of the success factors, and also raising the awareness of this issue to all employees to prevent this from happening again in the future.

This webcast was recorded at the facility of SmartFactory in Kaiserlautern, an industry/academia consortium of which Fujitsu is a partner too.

Whitepaper Trustworthiness: Safety Meets Security in Industry 4.0 Ecosystems. This paper is about holistically managing both functional safety and cyber security within a modern production environment. It's not just a future vision, Fujitsu’s OT Managed Monitoring Service is available for deployment today.

Related solutions

Hybrid IT

Seamless, secure, and sustainable transformation to address your business challenges and societal issues. Powering your next-gen connected enterprise.

Business Applications

Find out how Fujitsu and ServiceNow provide a foundation to enhance visibility, security, and predictive maintenance to your industrial operations and to protect you from the constant threat of cyber attacks.

Sustainable Manufacturing

Manufacturing for a harmonious coexistence between people and the planet. With our expertise, we are accelerating the creation of secure and resilient supply chains and a circular economy to achieve carbon neutrality.

Trusted Society

Creating an environment-first, resilient society in which people can live in peace and prosperity, with implementing and innovating trustworthy technologies to solve social problems together with countries, governments, citizens and business partners.

Why Fujitsu

We make OT cyber security protection available as a service

A partnership-driven approach with our customers and wider eco-system

Manufacturing and utilities industry experience, in NIS-D compliance, NIST, IEC 62443 and other sector-specific standards

Proven credentials in ISO27001 and ISO22301

40 years of cyber security experience with global and local capabilities

As well as being a world-class cyber solutions provider, we’re also a manufacturer - making us the ideal strategic partner to overcome the cyber challenges you face on the road to digital and sustainable transformation. We offer you a single point of contact to deliver your complete end-to-end OT Digital Transformation.

Our partners