Superpowers for a new generation of sustainable manufacturers

Fujitsu – smart manufacturing solutions for a sustainable future

Super-powering your factory transformation

Out of disruption, a new generation of manufacturers is emerging. A generation not defined by sector, region or number of years in business. But by a commitment to building sustainable manufacturing processes for a sustainable future. The question is - how to deliver on this change? By empowering your workforce through smart manufacturing technologies.

- Provide your people with advanced data and decision-making capabilities to unlock new value

- Enable them to meet ever-changing customer, operational and economic demands

- Empower them to make immediate, profit-focused decisions - saving energy, reducing waste and lowering your climate footprint

Whatever stage you’re at in your factory transformation, Fujitsu can partner with you to create new value. With our wide-ranging portfolio of intelligent manufacturing solutions, we can super-charge your makers to drive sustainable growth - for your business, society and our environment.

How to prime for sustainable growth in the manufacturing industry

Explore this IDC Industry Spotlight sponsored by Fujitsu and learn how you can prime for sustainable growth.

- Read expert advice on meeting sustainability goals while overcoming operating challenges in volatile, uncertain, and complex business environments.

- Discover how you can transform to ensure profitable outcomes while being a positive force in society.

Accelerating sustainable factory transformation

Today’s manufacturers are committing to success through sustainable manufacturing practices - investing in new values and initiatives to super-power their workforce. Work with Fujitsu and empower your people with smart manufacturing solutions and technologies. Sustainably transform your company across critical business areas:

- Resiliency – optimize your people, plants and processes in the face of constant movement

- Agility – visualize your data and make intelligent decisions, pursue improvements and opportunities for growth

- Capability – augment the power of your people, increase profitability, drive digital transformation and meet sustainability targets

Fujitsu - your sustainable manufacturing transformation partner

At Fujitsu, we believe in business transformation through human transformation. Change imagined by people, enabled through technology and delivered globally, in a co-creative approach.

As a manufacturer ourselves, we understand the challenge of constant change. And we’ve developed scalable digital solutions to innovate through unprecedented disruptions and achieve new levels of sustainability.

Let us help you to enable your people to achieve sustainable manufacturing. Get in touch to co-design your manufacturing transformation roadmap. Register with us and receive our insightful regular Manufacturing Community eNewsletter.

Sustainability in action: customer stories

Sustainable manufacturing solutions

Build trusted processes

Fujitsu Track and Trust Distributed Ledger Technology (DLT) builds a secure, trusted and connected ecosystem to manage your manufacturing data.

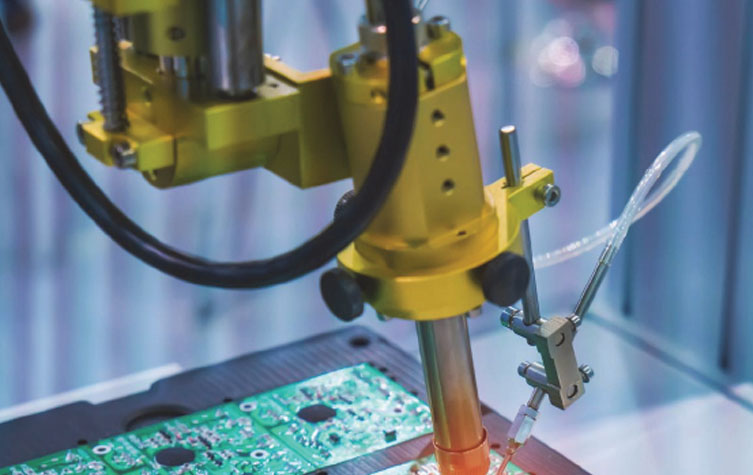

Enhance quality control

Transform your quality control processes - analyze and influence production and become more data-driven using Fujitsu Computer Vision.

Optimize factory operations

Find optimal solutions to operational problems using Fujitsu Quantum-Inspired Optimization Services, based on Fujitsu Digital Annealer.

React at speed to customer demands

Discover how to be more agile, flexible and responsive to customer demands with Fujitsu and ServiceNow.

Leverage strategic partnerships

Fujitsu and SAP combine deep production knowledge with agile business optimization to co-create smart manufacturing solutions.

At a glance

Established 1935

Over 126,400 employees worldwide

One of FORTUNEs 'World's Most Admired Companies’

Recognised as one of World's

leading Socially Responsible Companies

by Dow Jones

Fujitsu manufacturing knowledge hub

Sustainability is a top priority for manufacturing leaders

60% of manufacturers now believe sustainability is a vital business priority.

Download Fujitsu’s report on digital transformation trends to discover how and where technology can improve manufacturers’ sustainable credentials.

Order Management Solutions: Addressing the Customer Experience Gap in Digital Commerce

For the latest information on how OM solutions are enabling visibility across distributed inventories, and managing seamless and cost-efficient order fulfillment across multiple sales channels, download this IDC supply chain spotlight.

Fujitsu Technology and Service Vision 2022

In this latest edition, we explore the five important trends shaping the post-Covid-19 world and explain how responsible business will help to build a more sustainable future.