Tokyo, July 19, 2018

Key Points

- Researchers successfully used electricity obtained from high-efficiency concentrator photovoltaic cells (with an output of 470 W), currently under research and development at the University of Miyazaki, to electrolyze water, converting 18.8% of the solar energy (daily average) to hydrogen energy. This is the highest efficiency ever achieved by a practical system in an outdoor experiment.

- Deploying new electrical conversion equipment between the solar cells and the electrolysis equipment enabled researchers to provide a stable power supply to the electrolysis equipment without varying solar cell output loss due to weather conditions, thereby delivering the world's highest efficiency.

- The utilization of hydrogen energy obtained from the abundant sunlight of Miyazaki prefecture is expected to lead to local production and consumption of renewable energy.

Announcement Summary

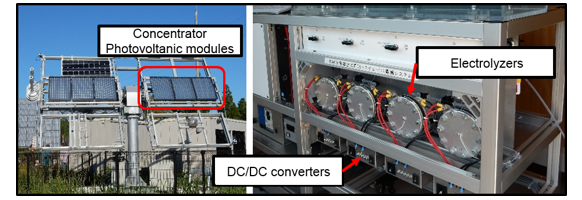

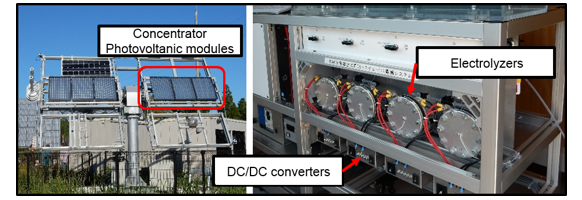

A research group consisting of Assistant Professor Yasuyuki Ota and Professor Kensuke Nishioka from the University of Miyazaki, Professor Masakazu Sugiyama of the University of Tokyo, Fujitsu Laboratories Ltd., and Sumitomo Electric Industries, Ltd., designed and built a system for water electrolysis using electricity obtained from high-efficiency concentrator photovoltaic cells (figure 1), successfully converting 18.8% of the solar energy (daily average) to hydrogen energy. Hydrogen has been promoted for use as a new energy carrier, with high expectations for the combination of renewable energy, such as solar power, with water electrolysis as a hydrogen energy production system that does not emit CO2. The University of Miyazaki has been working with the University of Tokyo to design and conduct a field trial of a system for producing hydrogen using solar cells and electrolysis equipment. Now, the research group has newly developed electrical conversion equipment (DC/DC converters)(1) that efficiently supplies electricity obtained from new high-efficiency concentrator photovoltaic cells(2) to polymer electrolyte electrolysis equipment(3), and has achieved an average daily energy conversion efficiency rate of 18.8% converting solar energy to hydrogen, in a field trial using actual sunlight. This field trial was able to manufacture hydrogen using the resource that is the abundant solar energy that falls on Miyazaki Prefecture, and local production and consumption of energy may be expected in Miyazaki Prefecture in the future.

Figure 1: The trial equipment used in the outdoor hydrogen production experiment at the University of Miyazaki.

Figure 1: The trial equipment used in the outdoor hydrogen production experiment at the University of Miyazaki.

Announcement Details

- Research Background and Problem Areas in Previous Research

The use of hydrogen is promising as a new energy carrier that does not emit CO2, and there have been ongoing efforts to create a hydrogen-based society. Currently, fossil fuel reformation technology, one of the primary methods for making hydrogen, is well established technologically, but it emits CO2 as part of the hydrogen production process. Furthermore, water electrolysis using electrical energy can emit CO2 depending on the power generation method used to produce the electrical energy. The combination of renewable energy, one type of which is solar power, and electrolysis has been proposed as one way of obtaining truly clean hydrogen, with the anticipation of establishing a totally CO2-free hydrogen supply system.

In their work on a hydrogen production system combining solar cells and water electrolysis equipment, the research group at the University of Miyazaki was able to achieve conversion efficiency of 24.4% from solar energy to hydrogen, the highest ever in the world, in a field test using a system that connected concentrator photovoltaic cells with ordinary polymer electrolyte electrolysis equipment(4). However due to changes in the operating temperature of the concentrator photovoltaic cells caused by outside air temperature and sunlight, as well as changes in the strength of sunlight due to factors such as clouds, it was difficult to maintain high hydrogen production efficiency throughout the day. Furthermore, it will be necessary to develop large-scale, high-efficiency hydrogen production systems in order to deploy large volumes of hydrogen sourced from renewable energy. As a result, the team felt it was desirable to conduct a field trial of long-term, high-efficiency hydrogen production in actual outdoor sunlight, closer to a true commercial implementation.

- Research Details

The research group, including Assistant Professor Yasuyuki Ota and Professor Kensuke Nishioka from the University of Miyazaki, and Professor Masakazu Sugiyama of the University of Tokyo, connected the new high-efficiency concentrator photovoltaic cells installed in the University of Miyazaki's outdoor testing area to water electrolysis equipment using polymer electrolyte membranes and to electrical conversion equipment (DC/DC converters), specially designed for this system by Fujitsu Laboratories Ltd., to efficiently convert the electricity obtained from the solar cells (figure 1). The result was the successful production of hydrogen throughout the day in actual sunlight, efficiently and stably. The average energy conversion rate of sunlight to hydrogen throughout the day was 18.8%, establishing a world record for a practical system.

With the previous experimental system, which directly connected the concentrator photovoltaic cells with the electrolysis equipment, because of variations in the maximum output (the point where maximum conversion efficiency is obtained) from the solar cells due to operating temperatures and the amount of solar radiation, there was an issue of lower conversion efficiency with operations that took place over many hours. Now, the electrical conversion equipment Fujitsu Laboratories newly developed for this system enables high energy conversion efficiency (90.0%) from the solar cells to the electrolysis equipment. This is achieved by controlling the voltage and electric current supplied to the electrolysis equipment, in accordance with the varying temperature and amount of solar radiation that change with the time of day, to consistently generate the maximum output from the solar cell.

Concentrator photovoltaic cells require optics-based designs for components such as lenses, and advanced tracking technology to ensure the lenses accurately face in the sun's direction, so it is not easy to improve power generation efficiency in actual outdoor environments. For this trial, the concentrator photovoltaic modules (manufactured by Sumitomo Electric Industries, Ltd.,) were mounted on a high-accuracy sun tracking mount at the University of Miyazaki, which serves as the research and development location for concentrator photovoltaic cells, and were able to achieve an average power generation efficiency (efficiency in converting solar energy to electrical energy) of 27.2% throughout the day in actual outdoor sunlight conditions in Miyazaki prefecture.

Going forward, the power generation efficiency of concentrator photovoltaic modules under actual operating conditions is expected to improve to 35%, and assuming an energy transfer efficiency of 80% from electricity to hydrogen in water electrolysis, it is anticipated that the energy conversion efficiency from sunlight to hydrogen will reach 25%.

- Future Issues and Developments, and Impacts on Society

Because the concentrator photovoltaic cells and electrolysis equipment used in this trial are already on the market, by using Fujitsu Laboratories' newly deployed electrical conversion equipment, it is possible to achieve hydrogen production from sunlight with a high efficiency rate of 18.8% with current technology. Furthermore, it is easy to extend the hydrogen production equipment used in this trial to large-scale solar power generation systems, making it an important technology in the scaling up of hydrogen production that will be needed in the future. Moreover, the hydrogen was produced using the sunlight falling on Miyazaki prefecture. This is a form of energy production that utilizes Miyazaki Prefecture's solar resources, and by storing and utilizing hydrogen produced in this way, and by developing new energy applications with hydrogen energy, local production and consumption of energy can be expected in Miyazaki.

Reductions in production costs are critical to the widespread use of hydrogen energy. Currently, concentrator photovoltaic cells are more expensive than ordinary photovoltaic panels, but outside of Japan, in areas of abundant sunlight with strong solar radiation, it has been possible to reduce energy production costs with greater generation efficiency. If gigawatt-level deployments necessary for hydrogen production move forward outside Japan, the price of concentrator photovoltaics may fall to a level equivalent with silicon photovoltaics. Combined with electrolysis equipment, the costs for which are falling due to technological advancements and mass production, these developments may reduce hydrogen production costs below Japan's Ministry of Economy, Trade, and Industry's target of up to 20 yen per cubic normal meter (Nm3)(5).

The newly developed electrical conversion equipment eliminated restrictions on system configuration between the solar photovoltaic power system and the electrolysis equipment, accelerating the scaling-up of solar-based hydrogen production. In order to further promote the spread of solar power generation systems and hydrogen production using electrical energy obtained from those systems, not only are further improvements in efficiency and reductions in cost necessary for the concentrator photovoltaic cells, electrical conversion equipment, and electrolysis equipment that make up these systems, there is also a need for improvements in system resilience in the face of changes in input power due to sudden changes in light levels. The research group hopes to contribute to the further spread of hydrogen sourced from renewable energy by advancing R&D so as to improve resilience based on further field trials.

Publication Details

Journal: Applied Physics Express

Paper title: "Highly efficient 470 W solar-to-hydrogen conversion system based on concentrator photovoltaic modules with dynamic control of operating point"

Authors: Yasuyuki Ota1, Daiji Yamashita2, Hiroshi Nakao3, Yu Yonezawa3, Yoshiyasu Nakashima3, Hiroji Ebe3, Makoto Inagaki4, Rui Mikami4, Yoshiya Abiko4, Takashi Iwasaki4, Masakazu Sugiyama2, 5, and Kensuke Nishioka6

1: Organization for Promotion of Tenure Track, University of Miyazaki, Miyazaki, Japan

2: Department of Electric Engineering and Information System, Graduate School of Engineering, The University of Tokyo, Bunkyo, Tokyo, Japan

3: Fujitsu Laboratories Ltd., Kawasaki, Kanagawa, Japan

4: Sumitomo Electric Industries, Ltd., Konohana, Osaka, Japan

5: Research Center for Advanced Science and Technology, the University of Tokyo, Meguro, Tokyo, Japan

6: Faculty of Engineering, University of Miyazaki, Miyazaki, Japan

URL: http://iopscience.iop.org/article/10.7567/APEX.11.077101

![]() E-mail: mbd-staff@ml.labs.fujitsu.com

E-mail: mbd-staff@ml.labs.fujitsu.com![]() E-mail: ueyama-munetsugu@sei.co.jp

E-mail: ueyama-munetsugu@sei.co.jp