Actions on Climate Change

We, Fujitsu Frontech Group, based on The Fujitsu Group Medium/Long-term Environmental Vision "Fujitsu Climate and Energy Vision", establish the target to reduce GHG (greenhouse gas) emissions, and take actions on climate change.

We have begun to take thorough actions on climate change, by establishing our own target to reduce GHG emissions (*1), in the wake of "Kyoto Protocol" adopted in 1997 and our acquisition of ISO14001 Certification in 1998. After that, in response to "Act on the Rational Use of Energy" revised and reinforced in April 2010 in Japan, and to power savings requested by the Government of Japan due to "Great East Japan Earthquake" on March 11, 2011, we reviewed and reinforced the actions on climate change drastically, for instance, by establishing our expertise committees of energy savings.

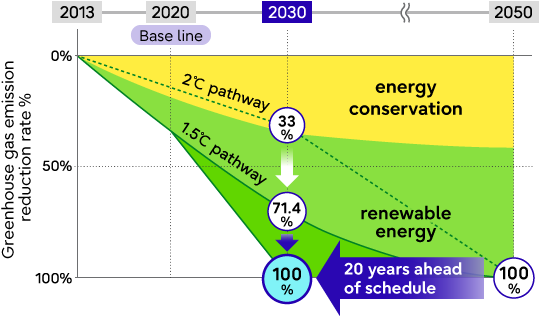

Recently, we have been carrying out more aggressive climate-related countermeasures such as increase of adopting renewable energy to realize "net-zero GHG emissions from the Group's business activities by FY2030", based on the Fujitsu Group Medium/Long-term Environmental Vision named "Fujitsu Climate and Energy Vision", which were recertified as a target compatible with Net-Zero standard by "SBTi (Science Based Targets initiative)" (*2) in June 2023.

- *1Established on the basis of "

Fujitsu Frontech Group Environmental Action Plan".

Fujitsu Frontech Group Environmental Action Plan". - *2Cooperative initiative which encourages businesses to establish targets to reduce GHG emissions, which are consistent with Paris Agreement scientifically.

Roadmap to Net-Zero

Emission reduction of Fujitsu Group (Scope 1 and 2)

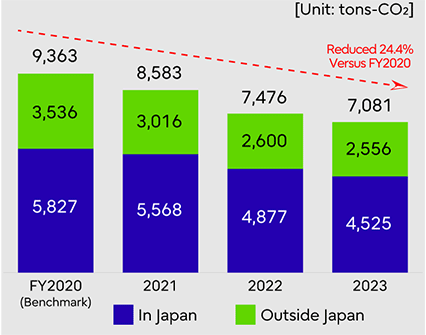

The Progress of GHG Emissions Derived from our Business

In the purpose of hitting the target in Fujitsu Climate and Energy Vision, we strive to reduce GHG emissions in and outside Japan, including the introduction of renewable energy (RE), LED lightings and fuel cell power generators. As a result, we could reduce about 2,281 tons-CO2 (-24.4%) compared to FY2020 in FY2023.

Progress of GHG Emissions

[Explanation about the bar graph]

- The sites included in it are Headquarters / Tokyo Plant, Niigata Plant and Kumagaya Service Solution Center (Kumagaya SSC) in Japan as well as FUJITSU DIE-TECH CORPORATION OF THE PHILIPPINES (FDTP: Philippines) and Fujitsu Frontech North America Inc. (FFNA: U.S.A.) outside Japan, which are all within the scope of Fujitsu Climate and Energy Vision.

- Conversion factor from purchased electricity consumption to CO2 is all "0.57 tons-CO2/MWh" (location-based), except for RE.

Main Countermeasures against Climate Change

Introduction of renewable energy

We have decided on a plan of "To introduce renewable energy in sites to 100% of all purchased electricity in our Group by the end of FY2030" to achieve RE100(*3) that Fujitsu Group participates in, and started forward-looking actions since FY2021. In Japan we introduced RE which was equivalent to about 13% of total electricity use in the whole Group in FY2023. Outside Japan, FDTP has completed the switch to 100% renewable electricity in July 2024. FDTP now runs businesses as 100% renewable electricity factories.

- *3It is abbreviation of "Renewable Energy 100%", which is an international initiative that participating companies try to switch all energy used in own business to RE.

Switching to LED lightings

In each site and each Group company, we make efforts to switch to LED lightings whose electricity consumptions are very few, with the result that they lead to reduction of a great amount of GHG emissions. Especially, FDTP has already finished replacing all the lightings with LED ones. In Japan, Kumagaya SSC and Totalizator Engineering Limited have replaced over 80% of lightings with LED ones.

| Sites | Numbers of LED Lightings

() is switched from mercury ones. | Notes |

|---|---|---|

| [In Japan] | ||

| Headquarters / Tokyo Plant | 139 (24) | Installed in front lobby, cafeteria, fitness room, etc. |

| Niigata Plant | 379 (128) | Replaced mercury lightings with LED ones. |

| Kumagaya SSC | 3,053 (17) | 82% has been switched to LED lightings. |

| TEL | 734 (0) | 86% has been switched to LED lightings. |

| [Outside Japan] | ||

| FDTP | 7,182 (83) | All has been switched to LED lightings. |

Replacement of mercury lightings with LED (Niigata Plant)

Introduction of LED lightings in the Plant (FDTP)

Switching to high energy-efficient facilities

In Headquarters / Tokyo Plant, we replaced large environmental test chambers to assure the quality of developed products, with recent models whose energy efficiency is about only 50% of electricity consumptions compared to conventional ones, during the period from FY2018 to FY2019 and in FY2023. This replacement demonstrated the effectiveness of reduction of a large amount of GHG emissions (the result of its measurement revealed the effectiveness of reductions of -70% or so).

In Niigata Plant, we optimized the number of power-transformers on the rooftop as well as replaced them with new ones whose loss of energy conversion is very few, in 2018.

In Kumagaya SSC, we have started operating solid oxide fuel cell (SOFC) generators, which are eco-friendly since 2020. This system enables us not only to generate about 50% of electricity consumed there, but to reduce a large amount of CO2 emissions compared to the case if we procure 100% of electricity from an electric power company.

Recent model of the chamber (Headquarters / Tokyo Plant)

Recent model of power-transformers (Niigata Plant)

Fuel cell power generators (Kumagaya SSC)

Improvement of facility operation

Besides replacement of facilities, we also improve our facility operation for energy savings.

For example, in Headquarters / Tokyo Plant, we did not only cover outdoor units on the rooftop with nets as sunshades to mitigate air conditioning loads in summer, but put bubble wrap sheets with thermal insulation on windows in winter.

In Niigata Plant, we do cover high temperature burn-in facilities to assure the quality of products before shipping, with aluminum insulation materials to confine released fever inside. This way enables us not only to control the operational frequency of attached air heaters, but to control the rise in room temperature during summer season, because the temperature within the facilities is kept in a certain degree.

Sunshades for outdoor units and insulation of windows

(Headquarters / Tokyo Plant)

Insulation of burn-in facilities

(Niigata Plant)

Operation of Energy Saving Committees

Based on "Act on the Rational Use of Energy" in Japan, we operate and hold a joint "Energy Saving Committee" which our Energy Management and Supervision Officer and Energy Management Planning Promoter also attend. Through this committee, for instance, we review, determine and implement the measures against some issues relevant to energy savings. And, we implement the PDCA Cycle appropriately by reviewing the effects, so that we can revitalize our energy saving activities.

Implementation of "energy saving patrol"

As one of energy saving activities, we implement "energy saving patrol" regularly in both summer and winter season, to keep in good condition, preset temperature of air conditioners on each floor. As a result, it contributes to saving energy.

Inspection by energy saving patrol

Inspection by energy saving patrol

Creative information displays related to power savings

As another of energy saving activities, we also make positive efforts to come up with creative displays, in the purpose of raising employee's awareness of energy savings. For instance, we create "Sticker for the proper preset temperature of an air conditioner" and "Poster for awareness with a digital thermometer" to display within offices.

Awareness of energy saving with displays

Reduction of Value-chain Emissions

On the grounds that it is not sufficient only to reduce CO2 emitted from our sites as actions on climate change, we are making efforts not only to grasp our value-chain emissions (from Scope 1 through 3), but to reduce emissions in Scope 3 (CO2 emitted from other companies, which are associated with us), as well.

Increase of energy efficiency of products

Because of comparatively high emissions rate of Category 11 "Use of sold products" in Scope 3 per total emissions in our whole supply-chain, we establish a target to reduce CO2 derived from product use, and make efforts to increase energy efficiency of products we develop.

Reduction of transportation CO2

FFNA, one of our Group companies outside Japan, has been taking part in "SmartWay Partnership®(*4)" since 2009 that U.S. Environmental Protection Agency (EPA) operates, and trying to improve the energy consumptions of freight transportation in North America region involved by FFNA.

FFNA strives to reduce the energy use during transportation through some measures mainly including the utilization of freight trucks which acquired certification of good environmental performance from EPA and the strategic adoption of 3PL (Third Party Logistics *5) to pursue more efficient transportation routes.

Incidentally, Niigata Plant, which is one of our Group sites in Japan, also makes an effort to reduce transportation CO2, through the improvement of transportation efficiency such as adoption of fuel economy trucks and pursuit of better trucking efficiency.

- *4It is voluntary public-private program that EPA launched in 2004, in the purpose of realizing the reduction of fuel consumptions and expenses as well as the mitigation of the environmental burden by accelerating the introduction of highly fuel-efficient technologies and operational methods in transportation. Recently, over 3,000 companies have registered this partnership and take actions.

- *5It is third-party outsourcing that business operators consign all the in-house logistics business to professional logistics companies which are familiar with efficient routes etc.

Registration Document of SmartWay

Registration Document of SmartWay

Other Actions

Participation in the events of local government

In Niigata Plant, we have participated in "Eco Office Award Initiative" sponsored by Niigata Prefectural Government, continuously since FY2016. Through this initiative, we make an annual plan to reduce CO2 emissions and submit to the government. And, after finishing 1-year actions based on the plan, we report on the results.

Incidentally, we won the prize named "Certification of Eco Office in Niigata" from the government in November 2019, because of us addressing the reduction of GHG emissions in FY2018.

The prize award ceremony

The prize award ceremony

Green Curtain

In Headquarters / Tokyo Plant and Niigata Plant, we create "green curtains" to mitigate the burden of air conditioners by preventing solar heat from penetrating walls directly in summer.

Headquarters / Tokyo Plant

Headquarters / Tokyo Plant