Sustainable Resource Use

We, Fujitsu Frontech Group, push forward with contributable actions to "Sustainable resource use" in a variety of phases of our business.

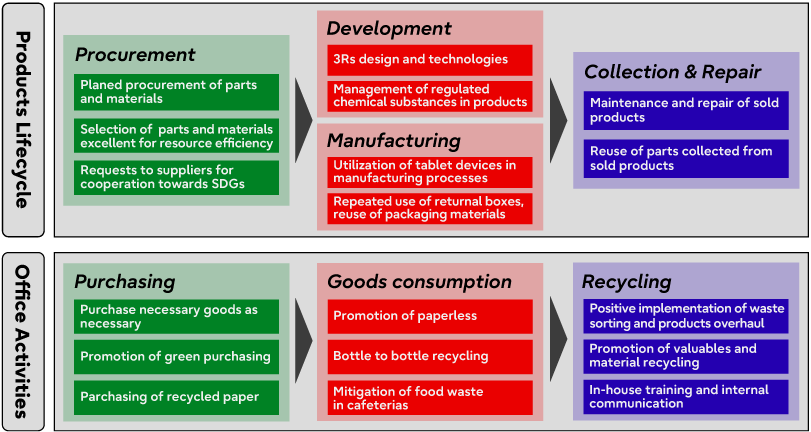

Our Concept toward Sustainable Resource Use

In our businesses, especially our products, we promote activities conducive to resource circulation in the whole lifecycle, not only by taking measures in each phase which is "Procurement", "Development" and "Manufacture", but by implementing "Collect and Repair" after delivering products to customers.

In "Development", we make efforts on such as reduction of mass and volume of products, reduction of the number of parts loaded onto products and partial adoption of bioplastic materials. In "Manufacture", we, for instance, implement reduction of paper use in process control by using tablets, utilization of returnable boxes and reuse of packaging materials. In "Collection and Repair", we promote mainly long-term use of products by maintenance and repair, as well as collection and reuse of parts loaded onto end-of-life products.

On the other hand, in our office activities, we take contributable actions to enhancing resource circulation, from viewpoints of "Purchasing of goods" and "Consumptions of goods" as well as "Recycling" in time of waste disposal.

As examples of "Recycling", we strive to fulfill in-house training relevant to recycling as well as to practice thorough waste sorting.

Examples of our actions toward sustainable resource use

Response to issues of plastic waste

We strive to reduce plastic waste which has negative impacts on environmental issues such as marine pollution and climate change. Up to now, we have taken measures including recycling of plastic parts and packaging materials.

Recently, we have started making efforts to reduce plastic waste in a more forward-looking manner than before, through reinforcement of our alignment between each site, enhancement of plastic-related in-house training or the like, based on the philosophy of "the Act on Promotion of Resource Circulation for Plastics" put into force in April 2022 in Japan.

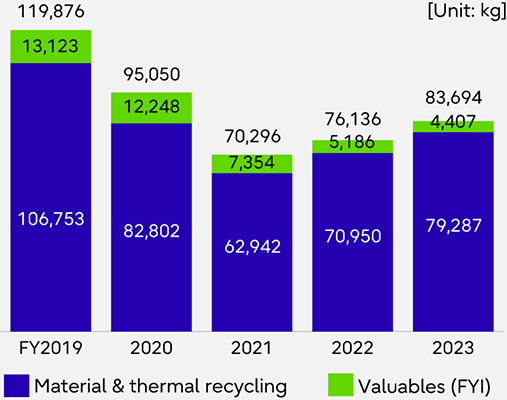

Incidentally, we, Fujitsu Frontech Limited, have all the plastic waste of ours treated as material or thermal recycling.

Progress of plastic recycling based on the Act (Fujitsu Frontech Limited)

Includes: Headquarters / Tokyo Plant, Niigata Plant, Kumagaya SSC and Construction Administration Dept.

Actions toward reducing plastic waste

As one of targets in "Fujitsu Frontech Group Environmental Action Plan XI" (FY2023 – FY2025), we set a KPI saying "Reduce plastic waste generations to 19% or more compared to FY2019 by the end of FY2025.", whose scope consists of our 3 sites which are Headquarters / Tokyo Plant, Niigata Plant and Kumagaya Service Solution Center (Kumagaya SSC). And, recently we have been able to reduce plastic waste generations to 18% versus FY2019 in FY2023.

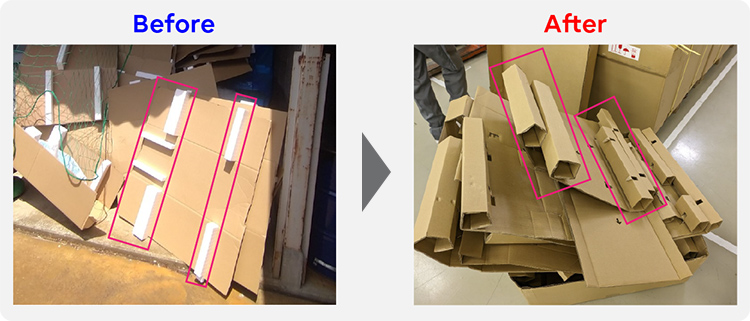

As examples of specific measures to reduce plastic waste, we, in cooperation with a beverage supplier, have adopted "Bottle to bottle" recycling (a way to recycle used PET bottles into new ones), concerning PET bottles disposed within our sites. Moreover, in Niigata Plant, we changed the design of package materials of our ATMs (FACT-X) from a type of combination of cardboard boxes and polystyrene foams into one of fully using cardboard boxes. As a result, we are now able to fully recycle the package materials as paper materials, although in the past it was difficult for us to recycle because polystyrene foams were pasted onto cardboard boxes.

Before and after of package materials

Resource-friendly procurement

Based on "Fujitsu Group Green Procurement Direction", we move ahead with green procurement together with our suppliers. As one of the activities, we not only hold an annual business briefing for the suppliers in order to explain about our procurement policy and so on, but make requests such as the consideration toward the recyclability of parts and packaging materials they supply us with, at the same time.

Resource savings and increase of resource efficiency in products development

In products development, we pursue resource savings and increase of resource efficiency, on the basis of 3Rs design and technologies (reduce, reuse and recycle). For instance, we make efforts to reduce mass and volume of our products, to decrease the number of parts incorporated into them and to partially adopt bioplastic materials to them.

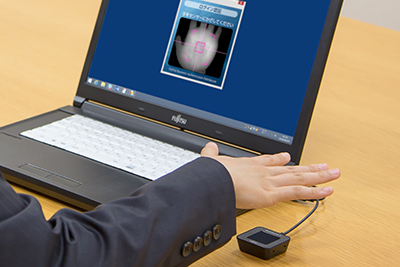

Moreover, we contribute to sustainable resource use in terms of "characteristic" of our products, as well. For example, RFID linen tags, whose durability is very strong, will lead to waste reduction, because the tags can be used again and again. In addition, Palm Vein Authentication, whose size of a device is very small, will contribute to resource savings, as this system can change the way of personal information management from conventional paper or card-basis to digital-basis with palm vein data.

Palm Vein Authentication

Palm Vein Authentication

Efforts in our factories

In our factories in and outside Japan, we take contributable actions to sustainable resource use, through a variety of measures. As an example, we reduce paper use by utilizing tablet devices instead of paper check-sheets in some manufacturing processes, in both Niigata Plant and Fujitsu Die-tech Corporation of the Philippines (FDTP).

Fujitsu Frontech North America Inc. (FFNA) has a large compactor to compress cardboards or the like for recycling. This machine enables to output a large amount of recyclable paper materials all at once, because it can compact them to 1/4 -1/5 in size. Thanks to this advantage, it is possible not only to decrease the frequency of their shipping but to save fuel consumptions in transportation. Furthermore, FFNA, for instance, also strives to reuse packaging materials like foamed polystyrene within its factory.

Use of tablet devices (FDTP)

Large compactor (FFNA)

Activities in our offices

In each site of our Group, we make efforts to reduce the volume of goods consumptions and waste generations, by implementing effective measures for resource circulation.

For example, we have been promoting "paperless" as one of measures in working style reforms since FY2017. Through this activity, we have already been accustomed to the working style without paper, such as Web meetings, utilization of large monitors at face-to-face meetings and digital operation of office documents.

In terms of waste reduction, we establish and operate expertise commissions concerning waste, so that we can work together by sharing information on good case studies between our sites, as well as can draw up and implement effective measures. Moreover, we try to communicate with our employees by sharing waste-related information on in-house bulletin boards and on our intranet or the like, in the purpose of letting each employee take actions in awareness of "resource savings".

Large monitor for meetings

List of sorting garbage

Contribution to resource circulation through Repair business

In Kumagaya SSC, we are running Repair business mainly for products we offer customers. Through this business, our repair staff with special skills and know-how about points of failure or the like, properly repairs about 30,000–35,000 broken products per year which are collected from customers. As a result of repair, the products can be used for longer. In addition, we also make an effort to collect similar parts from used products and to reuse them, so that customers can continue to use products necessary for parts whose production has been over, by repairing them.

Incidentally, FDTP and FFNA, our Group companies outside Japan, also run Repair business alike, because we share our know-how in Japan with them.