Tokyo, September 15, 2015

Fujitsu today announced that the Industrial Internet Consortium (IIC) has approved its proposed Internet of Things (IoT) testbed(1) solution model. Developed through Fujitsu's field trials and knowhow gained in its own production facilities, the Factory Operations Visibility and Intelligence model is intended to support the widespread use of IoT in production facilities.

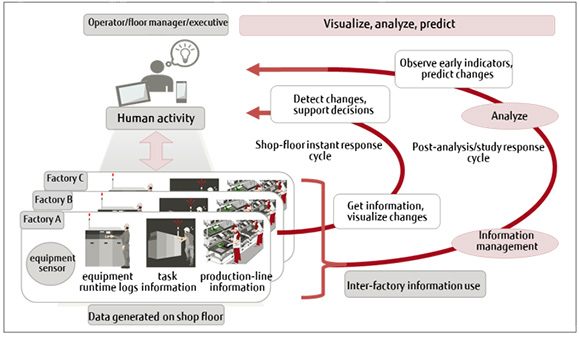

Under the theme of bringing visibility to production facilities, the model for the testbed Fujitsu has proposed uses the cloud to integrate a variety of data, such as operating information captured in real time from sensors attached to equipment, as well as related production plans and work results.

Fujitsu designed this testbed so that multiple companies, each in their own specialized fields, can collaborate and build an ecosystem of sensors, analytic applications, and other technologies. Through field trials and actual operations, Fujitsu aims to strengthen these solutions to respond to the diverse needs of customers.

The testbed will be exhibited at the Industrial Internet Consortium booth in the testbed demonstration area of the IoT Solutions World Congress in Barcelona, to be held September 16-18, 2015.

About the Industrial Internet Consortium

The Industrial Internet Consortium is a global organization founded on March 27, 2014 to accelerate the development, adoption, and wide-spread use of IoT in industry. At this point, with over 200 companies across 26 countries participating, they are promoting use-case analysis, architecture and framework planning, and the building of ecosystems on the basis of testbeds.

Fujitsu has participated in the IIC since its first meeting in June 2014. Now, as the only Japanese company on the Steering Committee, it is actively engaged in IIC operations, in addition to working group and technical activities.

About the New Testbed

As part of these efforts, Fujitsu proposed its IoT solution model, under the theme of factory visualization, based on the field trials and know-how gained at Fujitsu I-Network Systems Limited's Yamanashi Plant and the production facilities of Shimane Fujitsu Limited. Recognizing the utility of this proposal, the IIC has now approved it as its first testbed in Japan.

The new testbed aims to use IoT to make it easy to bring visibility to production facilities, to enhance worksite activities and raise motivation toward work, and to quickly evaluate the effects of cost reductions. In addition, since it has been approved as an IIC testbed, companies with a variety of technologies will be able to develop added value, such as, for example, analysis functions for making production lines more efficient.

Fujitsu will be making efforts, with many other companies, to continue evaluating field trials, planning a common architecture, and building and testing prototypes, to create a testbed with high interoperability which customers can test in a short period. Furthermore, the company aims to strengthen solutions to respond to all types of needs, incorporating the know-how gained from these efforts.

Factory Visualization through IoT

The testbed is designed to collect sensor data generated on the factory floor, production-equipment logs, production plans and statistics, operator information, and to integrate all this and other related information in the cloud. In this way the testbed can be used to bring visibility to production facilities, analyze and predict outcomes, and support better decisions for improvements. Because the current status can be digitally shared with all relevant people, it is possible to speed up improvement tests on the spot, and to propose optimal methods based on comparisons with other departments or factories. In this way it can be used to dramatically reduce operator-hours for automated production processes in small-lot manufacturing, or for manual processes in product reworks, as well as contribute to creating optimal team organization and human resource development.

"Fujitsu's Factory Operations Visibility and Intelligence Testbed is a huge step forward for the manufacturing industry," said Dr. Richard Soley, Executive Director, Industrial Internet Consortium. "By simulating an actual factory, FOVI will make it possible to visual and analyze key manufacturing processes to improve operational efficiency."