Archived content

NOTE: this is an archived page and the content is likely to be out of date.

FUJITSU Enterprise Application PRO-NES

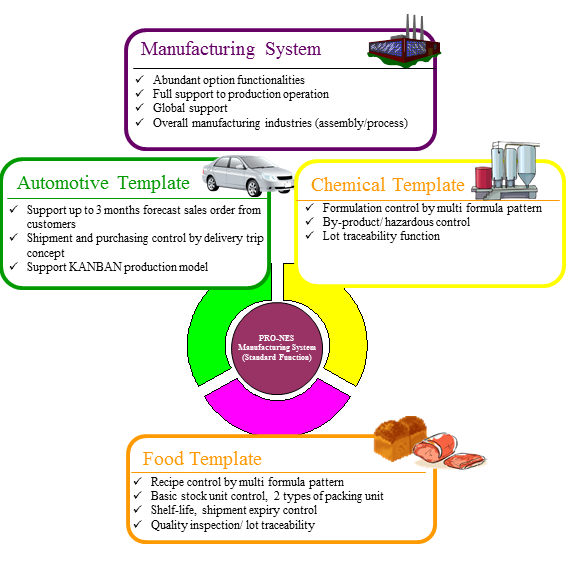

Industry Template

Apart from ERP solution, PRO-NES also provides complete, multi industry-specific solutions templates, developed to meet the unique requirements of specific industries, such as automotive, food and chemical. These industry-specific templates offer sophisticated functionalities, best practices and unsurpassed ease of use. These templates also allow PRO-NES to be mapped to various industry segments effectively and rapidly.

The available templates are depicted on the list below,

Automotive Template

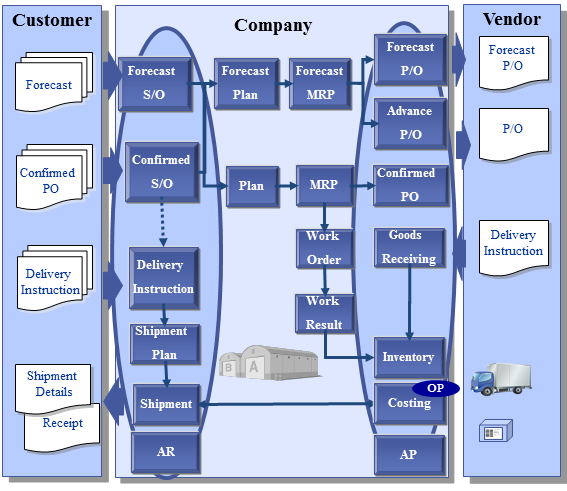

The automotive parts suppliers are constantly face with capacity glut, pricing pressure, quality pressure and fierce competition. These challenges required automotive parts suppliers to improve overall business process effectiveness and increase flexibility of their production systems. It is essential that the software solution allows Just-in Time and Pull method production to accommodate fluctuation of order volumes and to meet strict delivery schedules. PRO-NES Automotive template is designed with all the challenges in mind, to reduce cost and complexity within the automotive supply chain and to improve efficiency, speed-to-market and product quality.

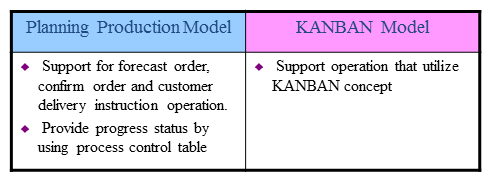

1. Planning Production Model

System Benefits

- Support unique delivery execution

Data import features enables you to import the received delivery instructions or confirm sales order data in CSV or interface file to system easily.

Data import features enables you to import the received delivery instructions or confirm sales order data in CSV or interface file to system easily.  Reflect the latest order changes to your ship plan promptly in order to handle urgent order/ changes.

Reflect the latest order changes to your ship plan promptly in order to handle urgent order/ changes. Depot control features enable you to manage your deliveries via depot.

Depot control features enable you to manage your deliveries via depot.- Effective utilization of forecast/ confirmed order and delivery instruction

Forecast order confirmed order and delivery instruction data import/ inquiry features are provided in order to eliminate the hassle of manual operation for data entering and confirm the transaction data status (e.g. delay/ ahead of the schedule) easily.

Forecast order confirmed order and delivery instruction data import/ inquiry features are provided in order to eliminate the hassle of manual operation for data entering and confirm the transaction data status (e.g. delay/ ahead of the schedule) easily.

Support requirement calculation according to the forecast/ confirmed order information in order to prepare the purchase order to vendor and work order to internal production line.

Support requirement calculation according to the forecast/ confirmed order information in order to prepare the purchase order to vendor and work order to internal production line. - Realize shop floor visibility through understanding the production process status

Confirmed S/O, Delivery Note (Customer) and Shipment Result information can be traced from the forecast information that received from customer, this information can be utilized for revising manpower plan and material order etc. in order to proceed production and avoid late delivery.

Confirmed S/O, Delivery Note (Customer) and Shipment Result information can be traced from the forecast information that received from customer, this information can be utilized for revising manpower plan and material order etc. in order to proceed production and avoid late delivery.

Process control table feature allow you to track production progress and the scheduled deliveries easily, so you can make changes to increase production efficiency and reduce costs.

Process control table feature allow you to track production progress and the scheduled deliveries easily, so you can make changes to increase production efficiency and reduce costs. - Improve planning process

Create forecast and normal production plan automatically based on the latest demand information with customer’s forecast and fixed order.

Create forecast and normal production plan automatically based on the latest demand information with customer’s forecast and fixed order.

Create fixed plan automatically by considering lot size and anticipated inventory information.

Create fixed plan automatically by considering lot size and anticipated inventory information.

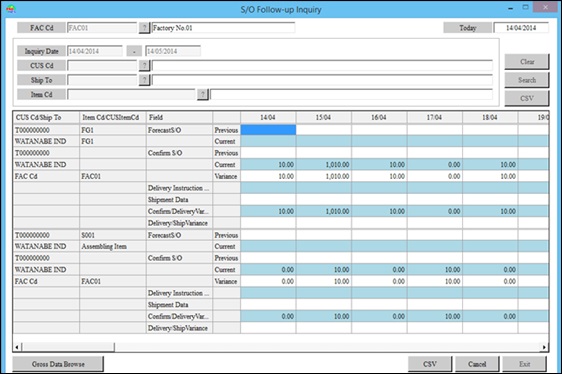

PRO-NES Sample Screen Image

S/O Follow-up Inquiry

S/O Follow-up Inquiry

Grasp the progress of confirmed S/O and Shipment result against customer’s forecast S/O.

Grasp the progress of confirmed S/O and Shipment result against customer’s forecast S/O.

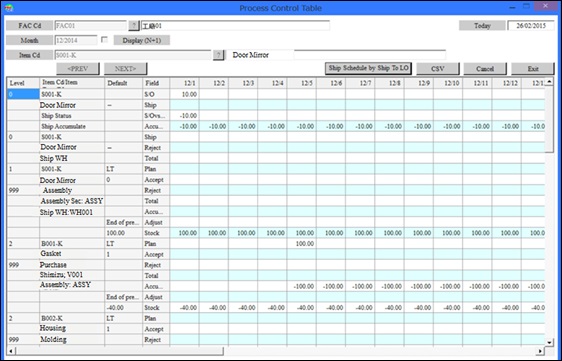

Process Control Table

Process Control Table

Monitor results (pass & fail quantity) corresponding to daily plans per finished goods structure parts.

Monitor results (pass & fail quantity) corresponding to daily plans per finished goods structure parts.

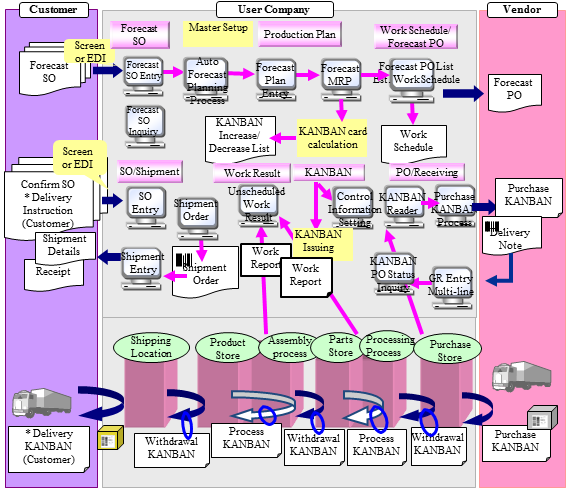

2. KANBAN Model

System Benefits

- Support pull production

The card quantity of KANBAN [Purchase, Withdrawal, Process and Supply KANBAN] are calculated automatically based on the existing month forecast demand enable to eliminate the hassle of manual operation.

The card quantity of KANBAN [Purchase, Withdrawal, Process and Supply KANBAN] are calculated automatically based on the existing month forecast demand enable to eliminate the hassle of manual operation. - Realize shop floor visibility

Monitor production result of work in progress enables you to grasp the production status.

Monitor production result of work in progress enables you to grasp the production status. - Optimize inventory level

Tracking and maintaining the incoming/ outgoing inventory in finished goods, work in progress and material basis enable to reduce excess inventory.

Tracking and maintaining the incoming/ outgoing inventory in finished goods, work in progress and material basis enable to reduce excess inventory. - Prevent delivery delay

Handling due date and result for sales order, shipment, purchase order and goods receiving based on [Date] and [Trip] to prevent delivery delay.

Handling due date and result for sales order, shipment, purchase order and goods receiving based on [Date] and [Trip] to prevent delivery delay.

Delivery date of goods receiving can be calculated based on the setting of delivery cycle (day-time-trip) and also day of the week by vendor unit in order to receive material just before the production.

Delivery date of goods receiving can be calculated based on the setting of delivery cycle (day-time-trip) and also day of the week by vendor unit in order to receive material just before the production.

PRO-NES Sample Screen Image

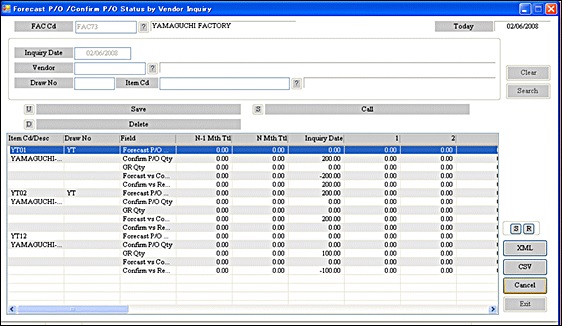

Forecast PO Confirm PO Status by Vendor Inquiry

Forecast PO Confirm PO Status by Vendor Inquiry

Understand the status between forecast purchase orders and confirm purchase order.

Understand the status between forecast purchase orders and confirm purchase order.

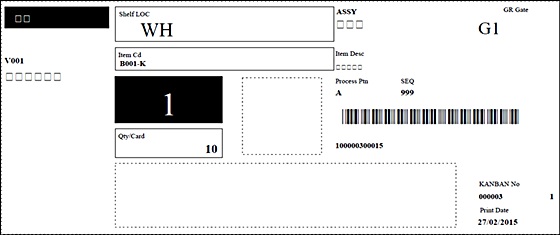

KANBAN Card

KANBAN Card

It is available for Purchase, Withdrawal, Process and Supply KANBAN.

It is available for Purchase, Withdrawal, Process and Supply KANBAN.

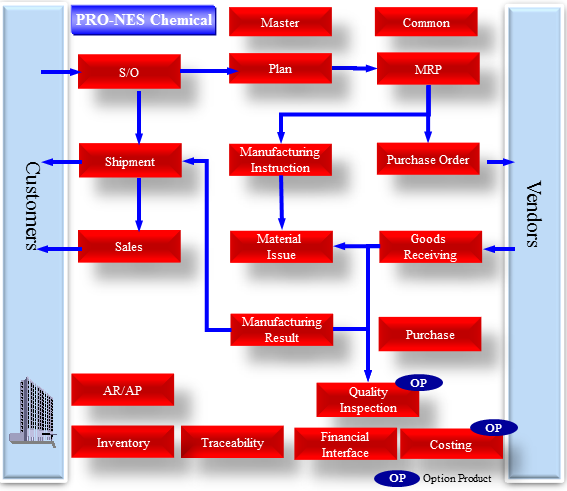

Chemical Template

Chemical processing industry normally has unique requirements for ERP systems. For instance, the system is able to handle complex formulation, packaging, and process issues. PRO-NES Chemical Template delivers all the necessary functionality required by chemical manufacturers. It designed to handle the specific needs of batch chemical production based on formulas, quality control (QC) testing, and expiration date control features. Inventory control with lot and location tracking, catch weight management, and other issues unique to chemical processing such as associate ingredients with process steps, is all integral features of the PRO-NES Chemical Template.

System Benefits

- Shortening lead-time for product master maintenance

Handle multiple formula patterns under a same product code.

Handle multiple formula patterns under a same product code. - Reduce losses from expired product/ material

Lot control feature for the product/ material inventory enables you to control product/ material lot with expiration date easily.

Lot control feature for the product/ material inventory enables you to control product/ material lot with expiration date easily.

Stock inquiry features enables the close-tracking of inventory lot that near to expiration date.

Stock inquiry features enables the close-tracking of inventory lot that near to expiration date.

Support allocating material lot for production according to the ordering of earliest expiration date.

Support allocating material lot for production according to the ordering of earliest expiration date. - Optimizing material usage

Support refilling orders and refilling formulas to enable you to reuse second-grade/ excess intermediate product as part of the material for the new work order.

Support refilling orders and refilling formulas to enable you to reuse second-grade/ excess intermediate product as part of the material for the new work order.

Enable to perform for the product which using both normal material and refilling material.

Enable to perform for the product which using both normal material and refilling material. - Track product's inventory in multiple packaging UOMs efficiently

Support tracking product's inventory based on 3 levels of packaging UOMs.

Support tracking product's inventory based on 3 levels of packaging UOMs.

Enable to define 3 levels of packaging UOMs under a same item and confirm packaging UOMs information from the transaction entry/ inquiry screens.

Enable to define 3 levels of packaging UOMs under a same item and confirm packaging UOMs information from the transaction entry/ inquiry screens. - Handling By-product efficiently

Support defining by-product in formula master of main product, creating work order for by-product based on production plan of main product, and monitoring work result of by-product.

Support defining by-product in formula master of main product, creating work order for by-product based on production plan of main product, and monitoring work result of by-product.

Enable to perform costing (Standard Cost) for By-product.

Enable to perform costing (Standard Cost) for By-product. - Realize traceability

Support both forward lot traceability from material through manufacturing processes to finished goods, and backward lot traceability from finished goods back into manufacturing processes or finally to material/ parts receipt from suppliers

Support both forward lot traceability from material through manufacturing processes to finished goods, and backward lot traceability from finished goods back into manufacturing processes or finally to material/ parts receipt from suppliers

Inventory lot which controlled under production line/ process basis enables you to track when and which departments/ processes have involved.

Inventory lot which controlled under production line/ process basis enables you to track when and which departments/ processes have involved.

PRO-NES Sample Screen Image

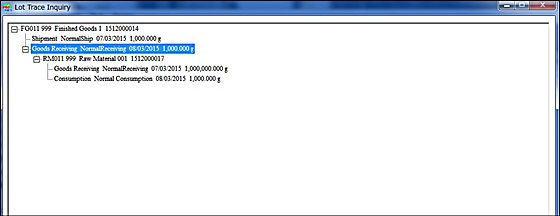

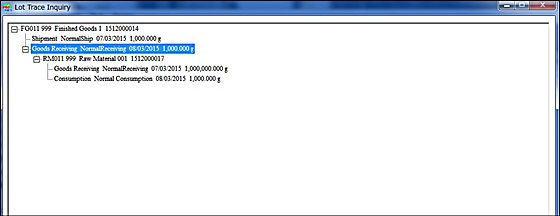

Lot Trace Inquiry

Lot Trace Inquiry

Support both forward/ backward lot traceability.

Support both forward/ backward lot traceability.

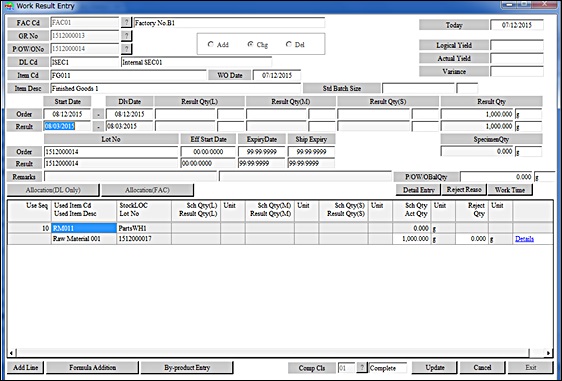

Work Result Entry

Work Result Entry

Maintain the work result and material consumption under a same screen.

Maintain the work result and material consumption under a same screen.

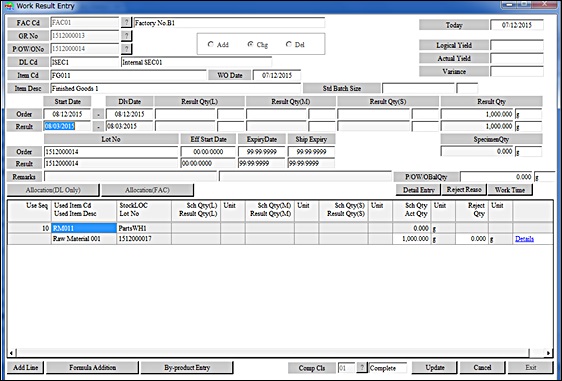

Food Template

Food processing industry normally has unique requirements for ERP systems. For instance, the system is able to handle complex recipe, packaging, and process issues. PRO-NES food template delivers all the necessary functionality required by food manufacturer. It designed to handle the specific needs of batch food production based on recipes, quality control (QC) testing, and expiration date control features. Inventory control with lot and location tracking, catch weight management, and other issues unique to food processing such as associate ingredients with process steps, is all integral features of the PRO-NES Food template.

System Benefits

- Shortening lead-time for product master maintenance

Handle multiple recipe patterns under a same product code.

Handle multiple recipe patterns under a same product code. - Reduce losses from expired product/ material

Lot control feature for the product/ material inventory enables you to control product/ material lot with expiration date easily.

Lot control feature for the product/ material inventory enables you to control product/ material lot with expiration date easily.

Stock inquiry features enables the close-tracking of inventory lot that near to expiration date.

Stock inquiry features enables the close-tracking of inventory lot that near to expiration date.

Support allocating material lot for production according to the ordering of earliest expiration date.

Support allocating material lot for production according to the ordering of earliest expiration date. - Track product's inventory in multiple packaging UOMs efficiently

Support tracking product's inventory based on 3 levels of packaging UOMs.

Support tracking product's inventory based on 3 levels of packaging UOMs.

Enable to define 3 levels of packaging UOMs under a same item and confirm packaging UOMs information from the transaction entry/ inquiry screens.

Enable to define 3 levels of packaging UOMs under a same item and confirm packaging UOMs information from the transaction entry/ inquiry screens. - Handling By-product efficiently

Support defining by-product in recipe master of main product, creating work order for by-product based on production plan of main product, and monitoring work result of by-product.

Support defining by-product in recipe master of main product, creating work order for by-product based on production plan of main product, and monitoring work result of by-product.

Enable to perform costing (Standard Cost) for By-product.

Enable to perform costing (Standard Cost) for By-product. - Realize traceability

Support both forward lot traceability from material through manufacturing processes to finished goods, and backward lot traceability from finished goods back into manufacturing processes or finally to material/ parts receipt from suppliers

Support both forward lot traceability from material through manufacturing processes to finished goods, and backward lot traceability from finished goods back into manufacturing processes or finally to material/ parts receipt from suppliers

Inventory lot which controlled under production line/ process basis enables you to track when and which departments/ processes have involved.

Inventory lot which controlled under production line/ process basis enables you to track when and which departments/ processes have involved.

PRO-NES Sample Screen Image

Lot Trace Inquiry

Lot Trace Inquiry

Support both forward/ backward lot traceability.

Support both forward/ backward lot traceability.

Work Result Entry

Work Result Entry

Maintain the work result and material consumption under a same screen.

Maintain the work result and material consumption under a same screen.