Fujitsu Develops State-of-the-Art AI Solution to Revolutionize Non-Destructive Testing Manufacturing Inspection

Fujitsu Laboratories of Europe Ltd.

News facts:

- Fujitsu Laboratories of Europe has developed an innovative AI technology that substantially accelerates Non-Destructive Testing (NDT) inspection procedures in selected manufacturing processes.

- The technology applies Fujitsu’s cutting edge deep learning, image and signal processing techniques to analyse NDT data and identify patterns that may indicate manufacturing defects.

- Fujitsu Laboratories of Europe’s new solution is capable of transforming current Quality Control (QC) procedures, automatically identifying interesting scan areas for defect inspection and typically reducing manual inspection procedures by 80 percent. Additionally, it continues to learn after deployment, improving performance on an ongoing basis.

- The result of a successful co-creation strategy between Fujitsu and manufacturing sector customers, the new solution has extensive deployment capabilities for any applications where non-destructive inspection techniques such as ultrasound, X-ray or imaging are used, including electronics, the automotive industry, aircraft production, pharmaceuticals, transport and infrastructure.

London, October 02, 2017

– Fujitsu has developed an innovative AI technology that significantly improves manufacturing quality control and defect detection by automatically analyzing and diagnosing Non-Destructive Testing (NDT) ultrasonic scan data in just minutes, helping to pinpoint potential defects more rapidly and efficiently than existing processes. Fujitsu Laboratories of Europe’s solution uses a new AI framework that combines image and signal processing techniques with deep learning technology to solve complex manufacturing quality problems.

The deep learning component of this new AI framework leverages the super-human ability of deep neural networks to process image data to detect relevant patterns, based on a unique set of technologies developed by Fujitsu Laboratories of Europe. This involves converting real-world data analysis challenges into an image analysis format, automating and accelerating the detection of relevant patterns in NDT ultrasound scan data, which may be indicative of manufacturing defects. Specialist manual inspection can therefore be rapidly targeted to potential defects, translating into an 80 percent reduction in the product area requiring an expert technician’s attention. As a result, quality control is considerably improved and potential bottlenecks in the production process are removed, with the potential to scale up production and make significant efficiency improvements. Additionally, Fujitsu’s solution has the capability to keep learning after deployment, enabling continuous performance improvement and an enhanced return on investment.

Dr Adel Rouz, Executive Vice President of Fujitsu Laboratories of Europe, explains the significance of this innovative technology approach: “We developed a generic machine learning engine for pattern detection, using a process that translates any raw data analysis problem into one involving image pattern recognition. Working with manufacturers, we can rapidly tune the solution to a specific application, thanks to its ability to learn from just a few training examples. This significantly minimizes the amount of annotated data needed from a manufacturer’s domain specialists, accelerating the entire set-up process. At Fujitsu Laboratories of Europe, we are focusing on a co-creation strategy to solve real-world manufacturing problems in record time, using the knowledge base of Fujitsu’s extensive manufacturing expertise combined with our state of the art AI innovations.“

Fujitsu Laboratories of Europe’s technology has already been successfully deployed in a variety of applications, including time-series sensor data, energy consumption, stock price analysis and smart manufacturing. In one application, it was applied to improve the retrieval of 3D CAD models from massive databases, helping to accelerate product design and enhance QC. In another example, the technology was applied to a social innovation application, detecting driver behavior via a discrete wrist-worn accelaration sensor. Potentially dangerous behaviors, such as eating and drinking or programming the GPS navigator while driving, were accurately classified, using a novel method for converting accelerometer time-series data into image representations, which were then fed to a deep neural network.

Fujitsu Laboratories of Europe is a Center of Excellence for Fujitsu’s advanced research into machine learning and deep learning, as part of the digital solutions and services being developed as part of Fujitsu’s Human Centric AI approach Zinrai. Fujitsu Laboratories of Europe’s activities include extensive collaboration and co-creation with Fujitsu customers and research organisations across Europe, including San Carlos Clinical Hospital in Madrid (with the HIKARI AI intelligent healthcare solution), the University of Seville (data analytics for tourism applications), and the 5G Innovation Centre in the UK.

Notes to editors

Fujitsu Laboratories of Europe’s new AI solution is part of Fujitsu’s digital solutions and services being developed under the Human Centric AI approach called Zinrai which comprises a comprehensive framework of component technology, such as machine learning, deep learning and visual recognition. In this new quality control application, the solution is applied automatically to analyse and detect relevant patterns in NDT ultrasound data. NDT is a non-invasive technique that is used for determining the integrity of materials or structures and enables the detection of internal defects in the test object, a technique that is widely used in industry as part of manufacturing quality control processes. Currently the detection of manufacturing defects in ultrasonic NDT is primarily a manual process, involving a thorough analysis of each section of the scan. For objects of large dimensions, this process can take several hours to complete. The operator uses visual cues, such as structure curvatures or discontinuities to flag potential defects. Fujitsu’s solution automatically identifies interesting scan regions that need to be inspected for defects, focusing the technicians’ effort on the relevant parts of the scans.

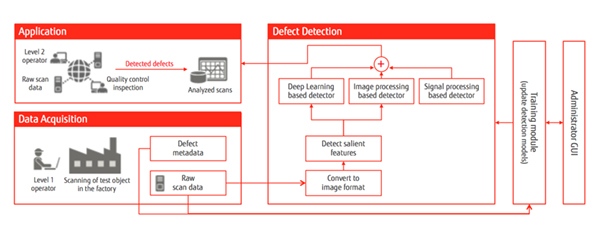

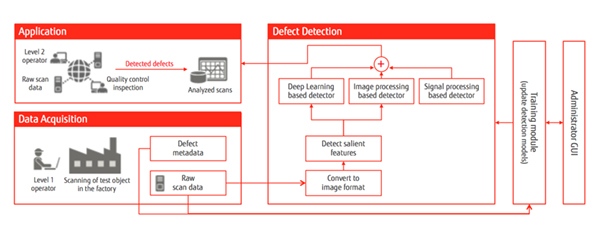

Figure: Fujitsu’s advanced solution uses AI to point the Level 2 operator to the regions of the scan that need to be inspected

Figure: Fujitsu’s advanced solution uses AI to point the Level 2 operator to the regions of the scan that need to be inspected

Related News

Online resources

About Fujitsu

Fujitsu is the leading Japanese information and communication technology (ICT) company, offering a full range of technology products, solutions, and services. Approximately 140,000 Fujitsu people support customers in more than 100 countries. We use our experience and the power of ICT to shape the future of society with our customers. Fujitsu Limited (TSE: 6702) reported consolidated revenues of 4.1 trillion yen (US $39 billion) for the fiscal year ended March 31, 2018. For more information, please see http://www.fujitsu.com.

About Fujitsu Laboratories of Europe

Established in 2001 and with an active presence in Europe since 1990, Fujitsu Laboratories of Europe Limited represents Fujitsu Laboratories across EMEIA, focusing on regional initiatives that reflect the diverse mix of countries and ideologies. Fujitsu Laboratories of Europe is focused on the creation of cutting-edge solutions that benefit society, adopting a co-creation strategy and working with customers, collaboration partners and society as a whole to pioneer a new generation of user-centric applications and services underpinned by creative information analytics. As one of Fujitsu’s global centers of excellence for AI, its work encompasses security, social innovation, manufacturing, AI ethics, and high performance computing applications. For more information, please see http://www.fujitsu.com/uk/fle/.

Georgina Garrett

Director

Phone: +44 1903 854900

Phone: +44 1903 854900

E-mail: fujitsu@garrett-axford.co.uk

E-mail: fujitsu@garrett-axford.co.uk

Company:Garrett Axford Ltd (on behalf of Fujitsu Laboratories of Europe Ltd)

All other company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Date: 02 October, 2017

City: London

Figure: Fujitsu’s advanced solution uses AI to point the Level 2 operator to the regions of the scan that need to be inspected

Figure: Fujitsu’s advanced solution uses AI to point the Level 2 operator to the regions of the scan that need to be inspected

![]() Phone: +44 1903 854900

Phone: +44 1903 854900 ![]() E-mail: fujitsu@garrett-axford.co.uk

E-mail: fujitsu@garrett-axford.co.uk