Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Immunity tests

ESD (electrostatic discharge)

Why: Test of the immunity to ESD coming from a user or object through physical contact (contact discharge) or contact via the environment (air discharge).

Testing method: Discharge up to 15 kV via a coupling plane or at all areas of contact on the tested equipment (e.g. drives, interfaces, chassis and switches).

Testing method: Discharge up to 15 kV via a coupling plane or at all areas of contact on the tested equipment (e.g. drives, interfaces, chassis and switches).

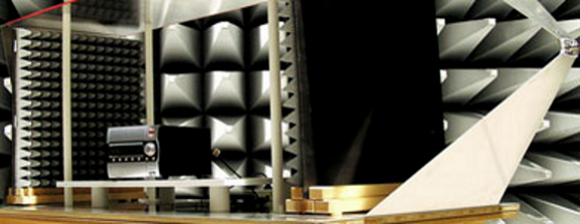

Radiated radio frequency electromagnetic fields

Why: Equipment needs to work without disturbance even when in close proximity to devices with high-frequency emissions (e.g. radio/TC, mobile, radio transmitters). This is particularly critical for monitors, sensors and audio cables.

Testing method: Radiate electromagnetic energy (e.g. with field strengths up to 20 V/m) and monitor the performance of the equipment being tested under the effect of the electromagnetic radiation.

Testing method: Radiate electromagnetic energy (e.g. with field strengths up to 20 V/m) and monitor the performance of the equipment being tested under the effect of the electromagnetic radiation.

Burst, fast transient voltage peaks

Why: Demonstrate the immunity of a product to disturbances originating from switching transients (e.g. interruption of inductive loads, relay contact bounce).

Testing method: Coupling of fast transient voltage peaks into power and data cables (up to 4 kV).

Testing method: Coupling of fast transient voltage peaks into power and data cables (up to 4 kV).

Surge, slow high-energy voltage peaks

Why: Evaluate the performance of equipment when subjected to high-energy disturbances on power and interconnecting lines caused by overvoltages from switching or lightning transients in the nearby environment.

Testing method: Coupling into power and interconnecting lines (up to 4 kV).

Testing method: Coupling into power and interconnecting lines (up to 4 kV).

Conducted disturbances induced by radio frequency fields

Why: Measure the immunity of a product to electromagnetic disturbances coming from intentional radio frequency transmitters. Equipment with at least one conducting cable (main supply, signal lines, earth connection) can be affected.

Testing method: Coupling of high frequency electromagnetic field into interconnecting lines with coupling networks or injection clamp.

Frequency range: 150 kHz to 80 MHz.

Testing method: Coupling of high frequency electromagnetic field into interconnecting lines with coupling networks or injection clamp.

Frequency range: 150 kHz to 80 MHz.

Power frequency magnetic fields

Why: Magnetic fields can influence the reliable operation of equipment and systems, especially when they contain magnetically sensitive devices.

Testing method: Equipment is subjected to magnetic fields at a level of 1 A/m to 30 A/m (up to a max. 100 A/m) and the suitable power supply frequency of 16 2/3 Hz or 50 Hz.

Testing method: Equipment is subjected to magnetic fields at a level of 1 A/m to 30 A/m (up to a max. 100 A/m) and the suitable power supply frequency of 16 2/3 Hz or 50 Hz.

Voltage dips, interruptions and variations

Why: Voltage dips and short interruptions are caused by faults in the network, installation or by sudden large load changes. Voltage variations are caused by continuously varying loads. Such disturbances may influence the operation of equipment and systems.

Testing method: Simulation of voltage dips, interruption or variations in the public power supply with specified voltage levels and interruptions times (beginning with 10 ms).

Testing method: Simulation of voltage dips, interruption or variations in the public power supply with specified voltage levels and interruptions times (beginning with 10 ms).