Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Liquid Loop Cooling

With unique liquid and air cooling mechanism inside, SPARC M10 can cool hot spots effectively.

Hybrid cooling technology - Liquid Loop Cooling (LLC)

Fujitsu has created a new cooling method combining the strengths of liquid and air cooling resolving a number of problems that exist in server cooling technology.

Air cooling is the standard server cooling approach, although it requires a heatsink to cool CPU and memory. This is done by evacuating hot air, absorbed from the surface of hot spots, from the servers. However, heatsink has two fundamental problems.

- Area heatsink is required to cool is destined to expand as performance and heat radiation become higher.

- Noise of the fan becomes louder as heat radiation becomes higher. Fans are necessary to move the hot air away from the server.

Liquid cooling also seems to have an inherent problem. Often used in super computers, it requires a large space and is very costly to install the dedicated cooling equipment. Partial rebuild of the datacenter may be required.

Fujitsu's Liquid Loop Cooling technology alleviates problems associated with server space, which generally grows as the processor's performance increases. Moreover it relieves the inconvenience of conventional liquid cooling's dedicated equipment and the related maintenance.

Six pumps for each processor effectively and continuously circulate cooling liquid inside tubes on hot spots. Plus, the dew prevention keeps pumps from their deterioration.

Performance effects of hybrid cooling

Servers with air cooling tend to occupy datacenter space more compared to liquid cooling. Not only does this result in problems with datacenter space, but it also creates server design restrictions, which negatively influence server performance. With Fujitsu's Liquid Loop Cooling, server performance has improved due to SPARC M10's ideal server design.

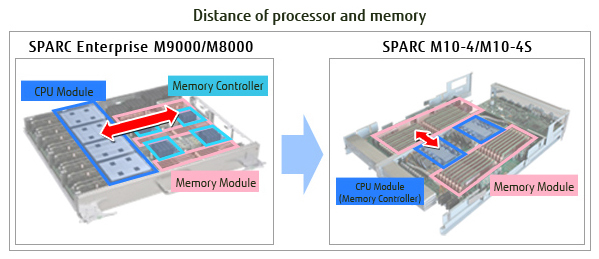

In order to cool hot spots with air, heat radiation units, including fans, must be located near hot spots. However this often results in components like memory or IO being further away from the processors. Distance between CPU and memory largely affects memory access time, degrading overall performance. In liquid cooling, heat radiation units can be separated from hot spots because heat is moved via cool liquid tubes to heat radiation units. This allows processors and other components like memory and IO to be close enough to reduce access time.

By not only eliminating server design restrictions, but also integrated memory controllers to the processor, memory access time is reduced to one-fifth of the previous SPARC server.

Saving power consumption and space

Through dispensing heat more efficiently, Fujitsu's Liquid Loop Cooling successfully reduced the dimension of the heat radiator by around 20%. Furthermore, this efficient cooling helps reduce the noise which may be created by lower fan rotation.

Parts lifecycle

Liquid Loop Cooling can contribute to longevity of server parts because it can cool the entire server more efficiently.