Find your way to Connected Manufacturing at Hannover Messe

Efficiency and transparency for a sustainable industry

Manufacturers are navigating many challenges, from climate disruptions and geopolitical tensions to financial uncertainties. Rather than seeing them as obstacles, reframing them as catalyst for innovation is crucial. Embracing comprehensive sustainability and operational effectiveness provides a path to harmonize benefits. Prioritizing this holistic approach can turn challenges into opportunities to drive transparency, efficiency, and sustainability.

Join us at Hannover Messe to see how leveraging Fujitsu’s advanced data capabilities, can give manufacturers a holistic view across their operations, enabling them to collect, manage and analyze data and achieve transparency, efficiency and sustainability.

Increasing transparency

Ensure quality consistency from upstream to downstream the value chain; data utilization is a core requirement for enabling traceability and transparency.

Enhancing efficiency

Drive cost efficiency by minimizing waste and resource usage and maximizing productivity. Drive agility through data-driven real-time supply chain insights for informed and rapid decision-making.

Driving sustainability

Reduce emissions, energy usage and waste, while effectively managing water and consumables. Accelerate sustainable growth by investing in the training and digital tools to help your people work more effectively.

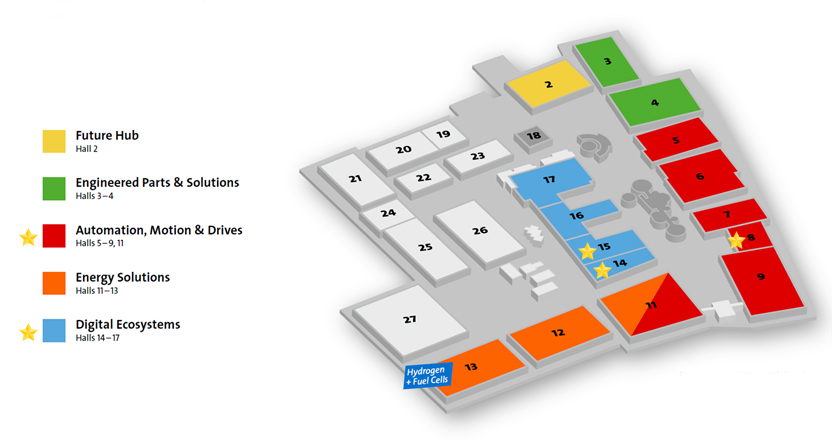

You can find Fujitsu in three locations

- Our Fujitsu dedicated booth: H62, hall 14

- With our partner SAP: E17, hall 15

- At SmartFactory.KL booth: D18, hall 8

What you can see on our booth:

Fujitsu provides data-driven, end-to-end solutions to help manufacturers drive efficiency and transparency. Through harnessing advanced data-capabilities and deep industry expertise, we are building a connected industry to create new value for our planet, our people and towards a prosperous digital society.

Deliver quality products and services in a timely and efficient manner with Digital Engineering

Engineering Accelerator

Accelerate your engineering processes by utilizing a cloud-based engineering environment with enhanced simulation capabilities, enabling manufacturing products to be brought to market quickly, and product energy and materials to be minimized. Fujitsu’s Engineering Accelerator utilizes a cloud based engineering environment to enable manufacturing that is adaptable to change, products to be brought to market quickly, and product energy and materials to be minimized.

Drive transparency across your value chain with AI enabled Digital Manufacturing:

OT Digitalization

As a manufacturer you face a tough challenge in which you are being asked to maintain uptime and physical safety, achieve compliant and sustainable production, continuously improve Overall Equipment Effectiveness (OEE) and gain a competitive advantage in new value chains. But in reality, a lack of overall strategy, disconnected governance and an inability to connect and protect operational technology (OT) make this a huge challenge. See how we can help you overcome these challenges, providing a one-stop service from the factory floor to the cloud for data collection, visualization, operation monitoring, and security services necessary for factory digitalization.

Smart Inspection

A manufacturers’ ability to ensure quality consistency from upstream to downstream the value chain is critical. In order to reach this target; manufacturers need to build their data capabilities to leverage digital tools effectively. Fujitsu’s advanced data capabilities, deep industry expertise and AI based quality inspection will help you increase product quality through improved defect detection rate, enable objective error assessment and root cause analysis, drive early detection of defective products/parts in the production process reduces scrap and accelerate quality inspection of more products.

Accelerate decision making with adaptable Supply Chain planning

Catena-X Trust ID for Global Data Spaces

Connect previously siloed data and systems to ensure manufacturing agility, sharing real-time information with the entire value chain. Catena-X provides a collaborative, open data ecosystem increasing efficiency and control. Additionally, you can enhance trust with ‘Trust-ID’, a solution that allows organizations to build trust across the supply chain through the seamless integration of global data ecosystems.

Contribute to your business and ESG goals simultaneously

ESG Solutions

In today’s climate-conscious world, manufacturers face the dual challenge of boosting production while fulfilling environmental, social and governance (ESG) obligations. As significant contributors to global emissions, the industry plays a pivotal role in mitigating climate impact. Embracing carbon neutrality isn’t just a moral imperative; it’s a strategic move that aligns with international efforts like the Paris Climate Accord and the push for net-zero emissions. By accessing real time data, adding informed context (assigning it to products and processes), providing dashboards and reports out of the box and utilizing our advanced simulation capabilities to optimize production planning, Fujitsu can help you reduce energy related costs, improve energy autonomy and comply with the latest regulations.

What makes Fujitsu unique?

- Deep ecosystem partnerships with best of breed technologies such as SAP, ServiceNow, Microsoft and Salesforce.

- Fujitsu is SAP's largest Digital Manufacturing partner with the most Digital Manufacturing installations globally.

- Fujitsu has a long heritage as a manufacturer, utilizing deep insight and knowledge to now help other manufacturers make their move to connected digital manufacturing. It takes a manufacturer to know a manufacturer.

- 360-degree understanding, enablement and refinement of a customer's people, systems, business model and processes via educational workshops, technology and consultative support.

Three reasons to attend Hannover Messe

- Explore how advanced technology drives connected manufacturing by enhancing transparency, efficiency, and sustainability through advanced data capabilities.

- Connect with our team to discuss how end-to-end manufacturing solutions can support your strategy, goals, and challenges, leveraging Fujitsu's global experience as a manufacturer.

- Network with industry peers to forge new connections. Partnerships are key to successful innovation, that’s why Fujitsu is SAP’s largest Digital Manufacturing partner with the most Digital Manufacturing installations globally.

Discover our latest connected manufacturing customer stories

tex.tracer

Blockchain is the basis of the whole tex.tracer structure and fashion supply chain

Meridian Energy Ltd

The new modern data platform offers a data environment that is delivering benefits in terms of recruiting and retaining talent, encouraging innovation and development from staff and visiting engineering students, and facilitating collaboration between internal functions.

Bidafarma

Creating an analytical algorithm that could calculate the most efficient delivery routes, saving 25% in fuel emissions and costs

Hunter Douglas

Hunter Douglas migrated more than 20 plants to the new SAP Manufacturing Suite and SAP S/4HANA®

Toll Group

Toll improved the reliability of the reports and data provided to its customers via a modern data platform in the cloud.

REHAU Industries

Optimizing product quality with the AI-based Quality Inspection solution from Fujitsu