Tokyo, June 20, 2018

Fujitsu today announced the establishment of the COLMINA Ready Program, a certification regime for Fujitsu Manufacturing Industry Solution COLMINA, a "digital place" connecting an array of manufacturing information, from design to production to maintenance, within the manufacturing industry. The program has begun full-scale operation in June.

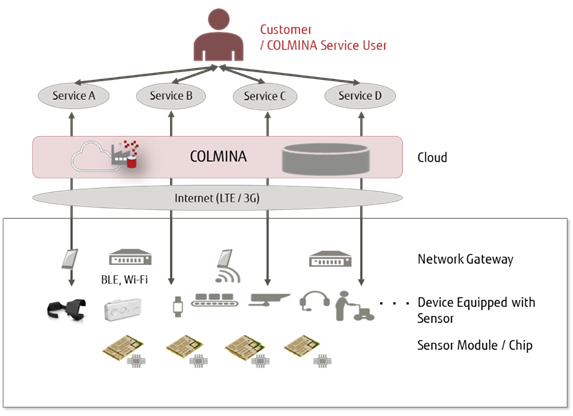

The COLMINA Ready Program is a scheme to certify that edge products, including various devices and sensors, gateways, and software deployed to manufacturing facility IoT systems, have been verified as compatible, or not, with COLMINA.

By combining products certified as compatible under this program with COLMINA, customers can create high quality IoT systems within a short time frame, as they will be able to quickly build systems that collect manufacturing and operating data from production facilities.

Going forward, Fujitsu will continue to further strengthen its collaboration with partners in order to develop new services using IoT data and business application data through the operation of this program.

Background

There has been an increasing trend toward the use of digital technology, particularly IoT, in creating innovation and enhancing competitiveness in the manufacturing industry. By offering COLMINA, Fujitsu has created a place where a great variety of manufacturing information can be connected, supporting the construction of IoT systems that link data from production facilities with business application data to provide features such as failure detection and visualization of production status.

At the same time, it is necessary to collect data from a variety of equipment and devices in order to use actual production facility information, and the time and effort required for the development and testing of such systems had become an issue.

COLMINA Overview

COLMINA Overview

Program Summary

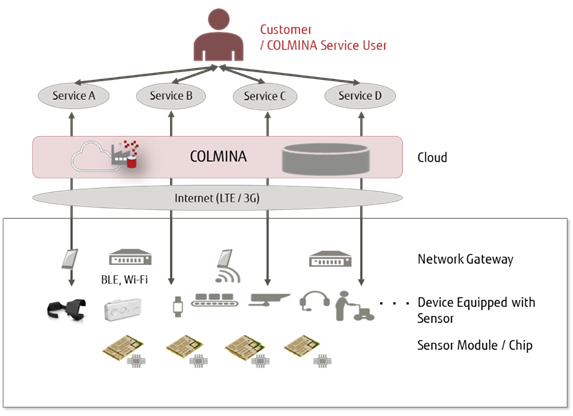

The COLMINA Ready Program checks the ability of edge products for IoT systems in manufacturing facilities, including sensors, gateways, and software, to connect to COLMINA, and certifies that verification has been done.

Fujitsu uses a specially prepared testing environment and COLMINA specification documents for the verification, connecting the product being tested with COLMINA and evaluating the data. With the support of Fujitsu technicians in completing a series of tasks, the verification process can be finished in a few weeks to a month, after which the certification information will be posted on a website.

COLMINA Ready Program Certification Flow

COLMINA Ready Program Certification Flow

Program Benefits for Customers

By combining certified products with COLMINA, customers are able to create high quality IoT systems, quickly building systems to collect manufacturing and equipment operational information from production facilities while limiting the amount of time and effort spent on development and testing.

Future Plans

Fujitsu will expand the number of certified products through this system, with a target of certifying a total of 200 product lines by the end of fiscal 2020.

In addition, using COLMINA, Fujitsu will create new services using business data and data collected from production facilities, and further enhance its collaboration with various partners.

Comment from Schneider Electric Japan Holdings Ltd.

As part of our Pro-face brand of programmable controller displays (human machine interfaces referred to as HMIs), we aim to make HMIs as well as their BLUE runtime software capable of serving as an operational display for automated equipment and devices. At the same time, we aim to enable the software to safely and easily collect operational technology (OT) information and convey it to a cloud server as an edge terminal. By participating in Fujitsu's COLMINA Ready Program, we expect that it will now be possible to collect the diverse information obtained through BLUE, with communication drivers to over 800 types of manufacturing facilities, both in Japan and elsewhere, and utilize it in Fujitsu's abundant visualization solutions using HMI.

Related Links

Fujitsu Begins Sales of Digital Solution "COLMINA" to Create Connected Services in the Manufacturing Industry (press release, May 9, 2017)