Tokyo, February 17, 2017

Fujitsu Limited and Fujitsu Advanced Engineering Limited today announced that FUJITSU Enterprise Application GLOVIA ENTERPRISE MES(1), a manufacturing execution system for customers in the assembly and manufacturing industry, has been enhanced by the addition of the new GLOVIA ENTERPRISE MES Smart Shop-Floor Option, which automatically collects and visualizes positional data of people and things in manufacturing facilities using beacons, as a service to promote the use of IoT in factories. The new Fujitsu Advanced Engineering-developed option is available in Japan beginning today.

With this new option, data that previously had to be entered by hand, such as manufacturing performance on the factory floor, or inventory status, can be collected, aggregated, and visualized in real time using sensing technology and beacons. In this way users can accurately understand the constantly changing status of work progress and hold-ups with precise timing, supporting the sort of advanced, on-the-spot decision making needed to manage a factory, such as fixing operational slowdowns and identifying bottlenecks.

Going forward, Fujitsu and Fujitsu Advanced Engineering will utilize the expertise gained with automated collection of data at manufacturing sites, obtained through these beacons, to provide broader solutions that connect to production equipment and smart devices, moving toward the smart factory, thereby contributing to a transformation in the way customers manage their factories.

Background

Going beyond just the pursuit of lower costs, recent trends of declining birthrates and an aging population in Japan have driven the need for front line manufacturing with operations that require fewer people and lower power, and while being of high quality, can meet customers' diverse preferences by producing a variety of different product models. Also, it is necessary to create a timely product-supply environment to meet demand. These issues are becoming management challenges that affect the business succession of customers in the manufacturing industry.

GLOVIA ENTERPRISE MES offers process management, inventory management and other functions, and through to manufacturing display and performance management, enables consistent manufacturing management. Now, Fujitsu and Fujitsu Advanced Engineering are using their strength in sensing technology and their operational experience gained from implementing numerous factory systems to offer new services that make smart assembly and manufacturing facilities possible.

Product Summary

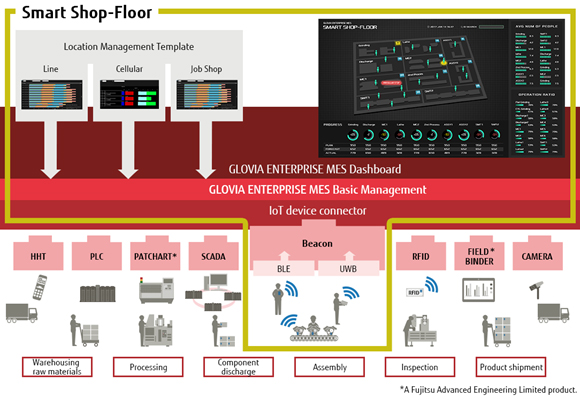

Figure 1: Diagram of GLOVIA ENTERPRISE MES Smart Shop-Floor Option

Figure 1: Diagram of GLOVIA ENTERPRISE MES Smart Shop-Floor Option

Figure 2: Beacon image (SENSOR LOGGER AZ002) (*2)

Figure 2: Beacon image (SENSOR LOGGER AZ002) (*2)

GLOVIA ENTERPRISE MES Smart Shop-Floor Option offers interface functionality that incorporates sensor data about people and things in manufacturing locations, database functionality that aggregates that data, and dashboard functionality that visualizes that data.

With this system, beacon sensors are attached to personnel, products, and on-site equipment, and their location information is automatically collected. From such location data, employees' work status (location, time they start a task, time that the task is completed, etc.), product production progress, materials used, and number and location of products and components in inventory can be understood in real time.

This system reduces the burden of inputting data, such as for daily operations reports and reports on work progress status that each employee previously had to fill out every few days, which facilitates accurate and timely factory management decision making.

Usage Scenarios

Fujitsu Advanced Engineering has prepared three dashboard templates for different production methods used in manufacturing facilities, aimed at improving various issues on-site.

Usage Scenarios

| Method |

Summary |

| Line production method |

Application: Standardizing lines in production facilities

Usage: A beacon is attached to each product, automatically collecting process progress status.

Effects: Productivity improvements through line balance optimization and visualization of bottleneck processes, timely component distribution through progress visualization preventing shortages and so forth. |

| Cellular production method(3) |

Application: Managing work hours for workers in production facilities

Usage: Each worker carries a beacon, enabling management of the number of workers, working times and job tasks based on collected location information.

Effects: Reducing the burden and preventing mistakes in inputting worker performance, improved work-cost accuracy for job-order production and so forth |

| Job shop production method(4) |

Application: Position management in production facilities

Usage: A beacon is attached to each product, enabling tracking and management of its location.

Effects: Understanding the location of items like products being worked on, products ready to ship, and products needing repair, reducing man-hours spent on searching within the factory and so forth. |

Pricing and Availability

Pricing and Availability

| Product Name |

Retail Price (Tax excl.) |

Availability |

| FUJITSU Enterprise Application GLOVIA ENTERPRISE MES Smart Shop-Floor Option(5) |

From JPY 1 million |

Late March |

Going Forward

"GLOVIA ENTERPRISE MES Smart Shop-Floor Option" is scheduled to be offered as a cloud-type service from the latter half of fiscal 2017 (Fujitsu's fiscal year begins April 1).

Sales Target

Sales of 100 systems over the next three years