Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Fujitsu Laboratories Develops Industry's First Bio-Derived, Water-based Paint

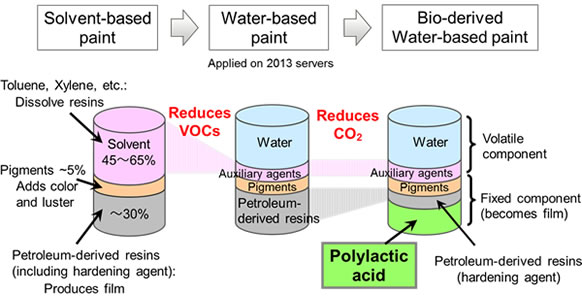

Reduces CO2 emissions by 60% and volatile organic compounds by 80% compared to solvent-based paint

Fujitsu Laboratories Ltd.

-

[1] Emulsion

Two types of liquids that will not mix with each other, but where one is scattered through the other as micro-particles. Mayonnaise and milk are typical examples of emulsions.

-

[2] Isocyanate

A compound where part has the structure -N=C=O. This carbon in an isocyanate is an electrophile that makes it highly reactive.

-

[3] Reduces CO2 emissions by 60%

CO2 is calculated over the entirety of the developed paint's lifecycle, from manufacture to disposal.

-

[4] Volatile organic compound

Organic chemicals that are gasses at room temperature, and disperse easily into the atmosphere. When released into the environment they cause health problems.

-

[5] 40% of all VOC emissions come from paints

Source: Fiscal 2013 Volatile Organic Compound Emission Inventory Study Group Report

-

[6] Mikasa Paint Company, Ltd.

Headquartered in Ichikawa, Chiba Prefecture, President Hiromasa Terauchi

About Fujitsu

Fujitsu is the leading Japanese information and communication technology (ICT) company offering a full range of technology products, solutions and services. Approximately 162,000 Fujitsu people support customers in more than 100 countries. We use our experience and the power of ICT to shape the future of society with our customers. Fujitsu Limited (TSE: 6702) reported consolidated revenues of 4.8 trillion yen (US$46 billion) for the fiscal year ended March 31, 2014. For more information, please see http://www.fujitsu.com.

About Fujitsu Laboratories

Founded in 1968 as a wholly owned subsidiary of Fujitsu Limited, Fujitsu Laboratories Ltd. is one of the premier research centers in the world. With a global network of laboratories in Japan, China, the United States and Europe, the organization conducts a wide range of basic and applied research in the areas of Next-generation Services, Computer Servers, Networks, Electronic Devices and Advanced Materials. For more information, please see: http://jp.fujitsu.com/labs/en.

Technical Contacts

Product & System Engineering Laboratories

Hardware Engineering Lab.

![]() E-mail: hel-pr@ml.labs.fujitsu.com

E-mail: hel-pr@ml.labs.fujitsu.com

Company:Fujitsu Laboratories Ltd.

All company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Date: 10 December, 2014

City: Kawasaki, Japan

Company:

Fujitsu Laboratories Ltd.