Kawasaki, Japan, December 03, 2014

Fujitsu Laboratories Ltd. today announced the development of a compact and slim RFID tag that can be affixed to ID cards, wearable devices, metal parts, and other objects that have limitations with regard to signal reception.

Until now, it was difficult to make RFID tags compact and slim enough to be affixed to metals or ID cards worn by people, as these hinder signal reception. For that reason, in order to ensure a communications range of two meters, for example, radio wavelength constraints meant that the tag needed to be at least 75 mm long or about 5 mm thick.

Fujitsu Laboratories has now developed a technology that uses a new looped structure of thin plastic to emit radio waves, resulting in the world's most compact and slim RFID tag(1), measuring 30 mm long and 0.5 mm thick, which can be attached to a wide range of objects.

This technology enables RFID tags to be used in a wide variety of applications, such as in the management of machine parts and in ID cards that people wear as a means of access control.

Background

In recent years, RFID systems, in which tags are attached to parts or products, and identifying information can be read by radio waves, have come into widespread use as a way to make parts management and product inventorying more efficient. The range of communications is dependent on the radio frequency. Frequencies in the UHF band, near that used by televisions and mobile phones, with relatively long communications ranges of a few meters, are widely used in RFID systems.

Technological Issues

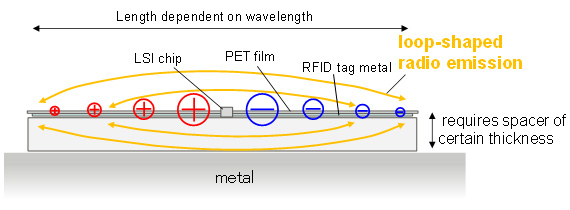

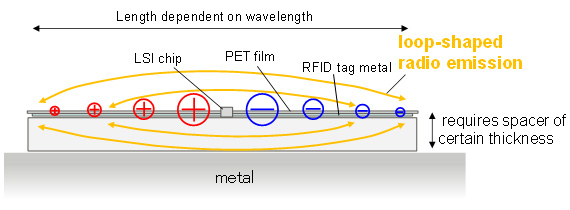

There is a need for RFID tags sufficiently slim and compact to be attached to any kind of object, at nearly any point on the object. Radio waves have difficulty traveling through metal and the human body, however, when RFID tags are directly attached to a metal object or an ID card carried on a person's body, which tend to disable communications. Accordingly, up until now, to create space between the RFID tag and the object to which it is attached, spacers of a certain thickness have been inserted to reduce the impact of the metal or human body, enabling communications ranges of a few meters.

For example, when using a spacer that is one mm thick, for communications to travel a distance of two meters or more, the RFID tag itself needs to be at least 75 mm long (one quarter the radio wavelength of approximately 300 mm).

Figure 1. Conventional RFID tags

Figure 1. Conventional RFID tags

Conversely, to enable communications to travel the same distance, it is possible for the length of the RFID tag to be reduced to 33 mm (one eighth the radio wavelength), but then the spacer needs to be at least 5 mm thick. In short, there has been a tradeoff between RFID tag length and spacer thickness that is dictated by the radio wavelength, making it difficult to achieve tags that were both compact and slim.

About the Technology

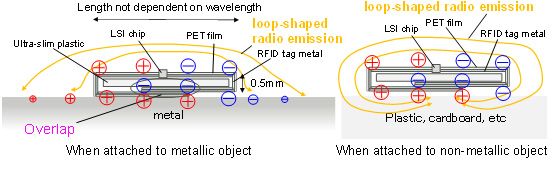

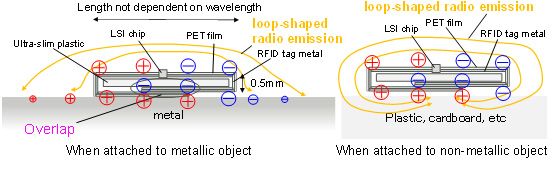

Fujitsu Laboratories has developed a technology that emits radio waves using a new looped structure in which the RFID tag is wound around rubber or plastic so that its ends overlap, overcoming the limitations imposed by wavelengths.

When tags of this type are affixed to metal, a large current (loop current) will flow in a way that follows the shape of the loop, and a portion of that current will leak through to the metal surface to which the tag is attached. The original radio waves generated by the loop current combines with the new radio waves being generated by the current leaking through to the adjacent metal, resulting in a combined signal that is emitted on the surface of the metal. Furthermore, in accordance with the desired target size of the tag, by adjusting the length and thickness of the overlap at the ends of the RFID tag, the degree of leaked current (the ratio of the two radio waves that are combined) can be optimized to maximize the communications distance. In other words, the metal to which the tag is attached and the RFID tag act as a coordinated source of current, functioning as an antenna emitting their combined radio waves, and thereby enabling communications to distances of several meters.

On the other hand, when the RFID tag is attached to a plastic ID card or cardboard instead of metal, there are only the radio waves generated by the loop current. This enables communications equivalent to metal as the radio signal efficiently propagates in a loop shape outward from the RFID tag, due to the absence of a metal object that would hinder the radio signal.

In addition, as the human body has a significant water component and is structured to easily carry an electrical charge, it can be treated the same as metal. An ID card with an embedded tag will act the same as when attached to metal, so the negative effects of being carried on the body are reduced.

Figure 2. The newly-developed loop structure

Figure 2. The newly-developed loop structure

Larger View (76 KB)

Results

This technology results in the world's most compact RFID tag, with a length of 30 mm and a thickness of 0.5 mm, which can be attached to any material.

This makes it feasible to attach tags to a wider variety of objects, such as for managing machine parts and in ID cards carried on the body as a means of access control, enabling RFID tags to be used in a variety of applications.

![]() E-mail: thin-small-rfidtag@ml.labs.fujitsu.com

E-mail: thin-small-rfidtag@ml.labs.fujitsu.com