Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Fujitsu Deploys New Wastewater Treatment System to Recover High Concentrations of Copper at its Nagano Plant

The new system slashes types of chemicals used by 75%

Fujitsu Limited

Tokyo, June 27, 2012

Fujitsu today announced that its plant in Nagano, Japan, has deployed Japan's first wastewater treatment system that enables efficient recovery of copper from industrial wastewater by producing sludge(1) with a high concentration of copper.

Fujitsu Facilities Limited, which is in charge of managing Fujitsu's facilities, deployed the new system produced by the Toshiba Corporation, enabling a high concentration (at least 90%) of copper to be recovered from copper-containing sludge and recycled at a profit while reducing chemicals and other impurities used in the wastewater treatment process. Moreover, by reducing the types of chemicals used by 75%, the new system places a smaller burden on the environment while reducing operational costs. Additionally, it shortens the processing time required and reduces the amount of space needed for the facility's wastewater treatment.

Fujitsu will now undertake tests to verify the effects of the new system while gaining operational know-how, and will consider extending the new system across other Fujitsu Group manufacturing facilities.

As part of the Fujitsu Group Environmental Protection Program, Stage VI(2), the Fujitsu Group is promoting reductions in the amount of waste it generates. The Nagano Plant, which focuses primarily on the development and production of printed circuit boards, has been working to improve the efficiency of copper recovery from the wastewater generated in the production of printed circuit boards. It has also been working to reduce the levels of sludge and the amount of chemicals used in the production process as well as the water treatment process.

About the Wastewater Treatment System

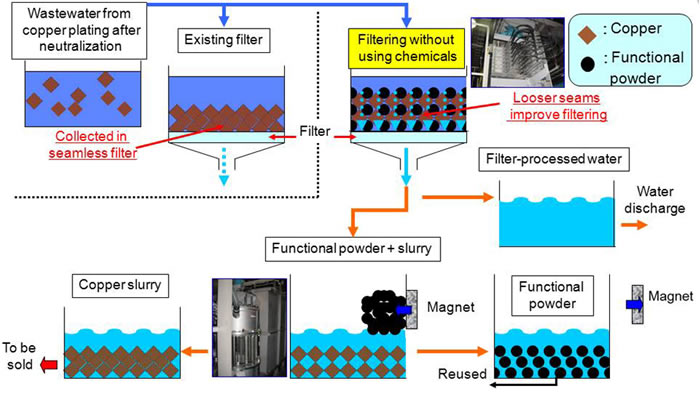

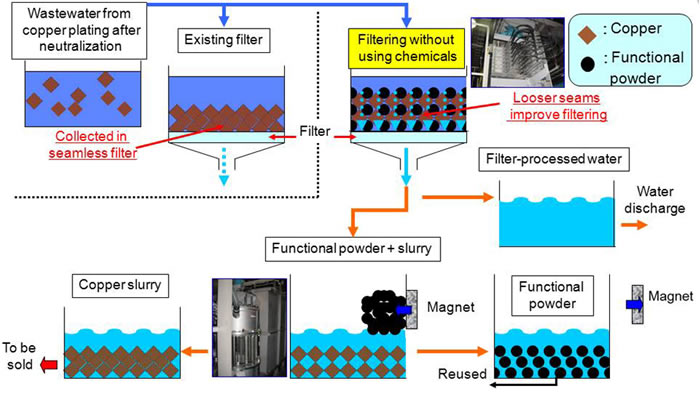

Copper particles in industrial wastewater are very fine, and therefore difficult to filter. For that reason, a coagulant(3) has been used in a coagulating sedimentation process to treat the wastewater, generating sludge that contains chemicals.

Through the use of a magnetic functional powder when filtering the wastewater, the new system is able to efficiently recover copper without using any chemicals other than a neutralizing agent. Prior to the introduction of this system, the Nagano Plant generated a large volume of sludge (35 tons per month) containing processing chemicals and other impurities, but since deploying the system it has been able to generate a much lower volume (5 tons per month) of sludge with a high concentration of copper, which increases the value of the sludge as a resource, therefore generating higher revenue. Moreover, since magnets can be used to easily separate the functional powder after filtration, it can be recycled and reused within the system, reducing operational costs by 40% (factoring in the revenue earned from selling the sludge for recycling) compared to previous methods. In addition, the processing time required is shorter, and the equipment of the new systems takes up approximately 50% less space than the equipment for the previous wastewater treatment system.

Figure: Overview of Water Treatment System

Figure: Overview of Water Treatment System

Figure: Overview of Water Treatment System

Future Plans

The Nagano Plant plans to gradually extend this system to other on site wastewater systems where applicable. Starting in October 2012, the plant also plans to deploy copper oxide conversion technology(4) that has been already been implemented within the Fujitsu Group, enabling it to process copper oxide, which has high added value. In addition, the new wastewater treatment system is capable of recovering valuable substances other than copper, prompting considerations for expanding its use at the Nagano Plant and extending the new system to other Fujitsu Group manufacturing facilities.

About Fujitsu

Fujitsu is the leading Japanese information and communication technology (ICT) company offering a full range of technology products, solutions and services. Over 170,000 Fujitsu people support customers in more than 100 countries. We use our experience and the power of ICT to shape the future of society with our customers. Fujitsu Limited (TSE:6702) reported consolidated revenues of 4.5 trillion yen (US$54 billion) for the fiscal year ended March 31, 2012. For more information, please see http://www.fujitsu.com.

Press Contacts

Public and Investor Relations Division

Inquiries

Company:Fujitsu Limited

All company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

Date: 27 June, 2012

City: Tokyo

Company:

Fujitsu Limited,

,

,

,

,

,

,

,

,

,