Tokyo, May 26, 2011

Fujitsu today announced the release of GP4, a new software for simulating the movements of production line workers, which is designed for customers in the manufacturing industry, such as automobile parts suppliers and precision electronics manufacturers. The new software is available starting today in Japan.

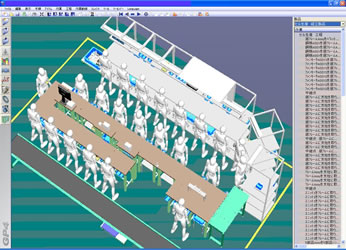

With GP4, users at the production preparation stage can create a virtual production line and run simulations on factors including the most efficient movements or positions of production workers, the optimal alignment of workers in relation to the flow of a production line, and the time required to complete specific production tasks. As a result, in addition to enabling greater efficiency in assembly work on a production line from the standpoint of people, the product enables workers to benchmark their work against the simulation results and share their understanding of problem areas with co-workers, leading to improvements on the front lines of assembly plants.

In addition, by using GP4 in conjunction with Fujitsu's virtual product simulator (VPS), a 3D virtual verification simulation tool for verifying assembly processes, users are able to verify the optimization of assembly processes from the dual perspectives of both the end product and the workers on the production line, thereby further improving manufacturing productivity.

A 40% reduction in production line assembly time was achieved in an early-release [beta-release] deployment of the software.

With the addition of this software to the company's line of product lifecycle solutions for the manufacturing industry, Fujitsu now offers support through information and communications technologies across the entire product lifecycle, from product planning to design, production preparation, production, and maintenance. Fujitsu is committed to delivering one-stop support for customers in production innovation in order to contribute to enhanced corporate competitiveness.

GP4 was developed by Lexer Research Inc., which has extensive experience and expertise in the preparatory processes for manufacturing operations.

Background

In the manufacturing industry in recent years, great progress has been made in the area of production innovation prior to actual production, including virtual product design using 3D CAD, or simulations of assembly processes as opposed to relying on production prototypes. However, as workers are the key to raising productivity on a production line, it is difficult to perform verification in virtual environments, necessitating a resort to a process of trial-and-error on the production line in order to improve efficiency.

To address this problem, Fujitsu is releasing GP4, a new software product for simulating the movements of production line workers.

Product Features

1. Enables production line optimization through simulations of the movements of production line workers

With GP4, users are able to simulate the most efficient movements or positions of production workers, as well as the optimal alignment of workers, by configuring the basic movements of production workers (such as patterns of walking or patterns of hand or arm movements) in the designed virtual production line, and then applying MOST(1). The time required to complete specific production tasks can also be automatically calculated. Through mathematical modeling, evaluation, and analysis of the workers, end product, and machinery, GP4 will enable the realization of the optimal production line.

2. Enables evaluation and verification of assembly processes from the dual perspectives of end product and people when combined with Fujitsu's VPS

By using GP4 in conjunction with Fujitsu's virtual product simulator (VPS), a 3D virtual verification simulation tool for verifying product assembly processes, users are able to verify the optimization of assembly processes from the dual perspectives of both the end product and the workers on the assembly line.

3. Enables know-how on production efficiency to be leveraged globally

For customers who are expanding their manufacturing capabilities globally, the use of GP4 when preparing a mass production facility outside of Japan enables them to remain in Japan while supporting the preparation process. This eliminates unnecessary trips and reduces costs and production start-up times.

4. User-friendly operation, even for novices

Skill and training are required to effectively use CAD, but GP4 is very user-friendly enabling first-time users who have never used simulation software to employ it with ease.

5. Use of virtual equipment for constructing approximately 400 different types of production lines enables quick design of virtual line

Designs of the virtual production line used in the simulation can be completed quickly by using the roughly 400 different types of virtual equipment templates built-in to the software.

Pricing and Availability

Pricing and Availability

| Product Name |

Pricing (excluding taxes) |

Availability |

| GP4 |

Manufacturing

Line review / balance review / work-flow review / line evaluation |

Starting from 4 million JPY |

Immediate |

RACK

Semi-automated production of parts rack |

Starting from 800,000 JPY |

Immediate |

PROJECT

Supports visibility in production planning for heavy industry |

Starting from 5 million JPY |

Immediate |

Manufacturing Executor

Software for playback only |

Starting from 800,000 JPY |

Immediate |

Manufacturing SDK

Development tool for customization |

Starting from 800,000 JPY |

Immediate |