- The possibilities

-

About K computer

- What is the national development project of the K computer?

- The K computer is incredibly fast

- "SPARC64™ VIIIfx": A Fast, Reliable, Low-power CPU

- Innovative "6-Dimensional Mesh/Torus" Topology Network Technology

- Global Challenge and Fujitsu

- Quick guide to supercomputing

- Look into the K computer

- Supercomputing explained in three minutes

- Events

- Topics

- Brochures

- Links

Archived content

NOTE: this is an archived page and the content is likely to be out of date.

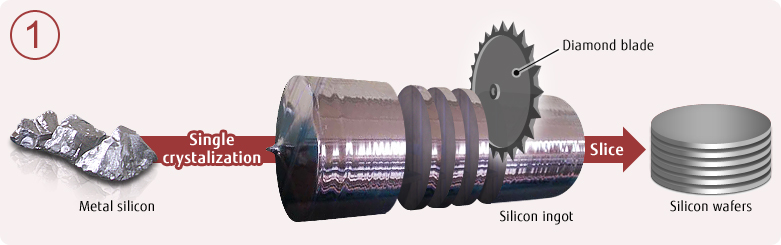

How to Create a CPU

How is a CPU, the heart of a supercomputer, created?

Silicon ingot is sliced to create silicon wafers

A large silicon monocrystal or ingot (99.999999999% pure) is sliced by a diamond blade to create thin silicon wafers.

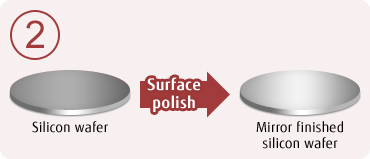

The surface of the silicon wafer is polished to create a mirror finish.

Process the surface to make semiconductors

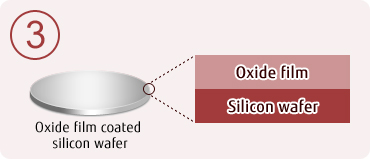

An oxide film is grown onto the wafer.

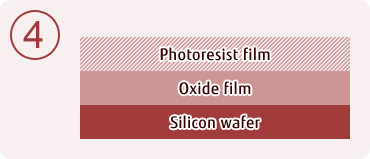

A photoresist film is coated on the wafer surface.

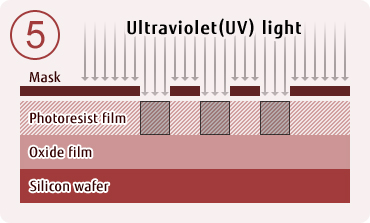

The photoresist film is exposed to ultraviolet (UV) light through the pattern on the mask.

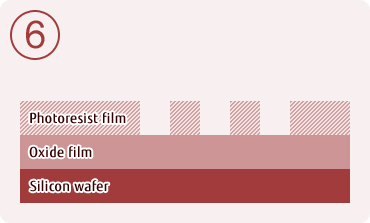

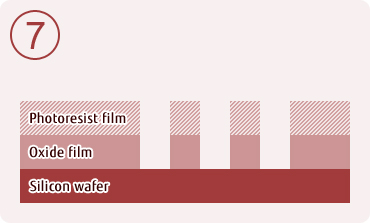

The photoresist region that was exposed to the UV light is removed using a developer. (The exposed area changes to a substance that is dissolved by the developer.)

The oxide film is then removed using a caustic agent. This exposes the silicon surface.

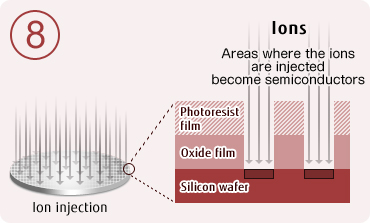

The required ions are then injected into the silicon surface. The character of the silicon then changes into a semiconductor, which is a state where elements with electrical characteristics can be created.

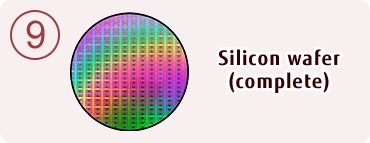

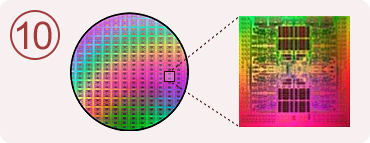

Elements with electrical characteristics are then created by connecting wires and creating circuits. Many chips can be created on the same silicon wafer. Wafer probers are used to electrically test the chips and define good or bad chips.

Note: This image has been simplified for illustration purposes. On an actual wafer, solder bumps are formed for connection to the package board.

CPU separated from the silicon wafer

Good chips are separated from the silicon wafer.

Note: This image has been simplified for illustration purposes. On an actual wafer, solder bumps are formed for connection to the package board.

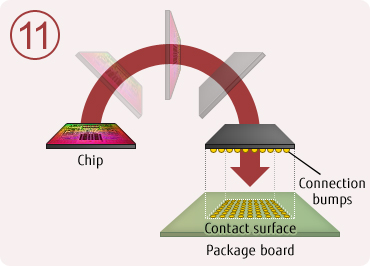

The solder bumps on each separated chip are matched to the ceramic or resin package board.

Note: This image has been simplified for illustration purposes. On an actual wafer, solder bumps are formed for connection to the package board.

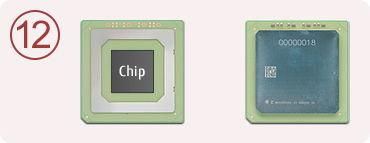

A heat sink to efficiently remove heat is attached onto the package board where the chip is mounted. The CPU is now complete. After various tests, only the good products are selected for use.

- What is the national development project of the K computer?

- The K computer is incredibly fast

- "SPARC64™ VIIIfx": A Fast, Reliable, Low-Power CPU

- Innovative "6-Dimensional Mesh/Torus" Topology Network Technology