- Policy and Action Plan

- Our Customers and Society

-

Reduction of Environmental Burden in Our Business Activities

- Reducing Greenhouse Gas (GHG) Emissions and Boosting Energy Intensity at Our Business Sites

- Environmental Management and Communication with Society

- Environmental Data

Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Reducing Greenhouse Gas (GHG) Emissions and Boosting Energy Intensity at Our Business Sites

Our Approach

The Fujitsu Group believes that prevention of global warming is a priority issue. Accordingly, we have formulated the "FUJITSU Climate and Energy Vision," Fujitsu's medium/long-term environmental vision, and aim to eliminate all CO2 emissions from our business activities by 2050.

The primary GHG emissions from our business sites (plants, offices, and datacenters) are CO2 accompanying energy (electricity, fuel oil, and gas) usage, and perfluorocarbon (PFC), hydrofluorocarbon (HFC), sulfur hexafluoride (SF6), and nitrogen trifluoride (NF3) used in semiconductor manufacturing. In addition to complying with relevant laws, we have set reduction targets for these and are striving to decrease and control the amounts we use and emit.

Reduction of CO2 Emissions due to Energy Consumption

CO2 emissions due to energy consumption are responsible for about 90% of the Fujitsu Group's greenhouse gas emissions. Therefore, we continuously work to improve the following energy-saving measures to reduce CO2 emissions.

- Energy-saving equipment, focusing on motive-power facilities (introduction of free cooling, inverters, energy-saving facilities, fuel conversion, etc.)

- Increased efficiencies through revised manufacturing processes, accompanied by proper motive-power facility operation and improvement of management

- Adjusting appropriate room temperature for office air conditioning, saving electricity for lighting and office automation equipment

- Promotion via measurement of energy consumption visualization and proactive use of that data

- Use of renewable energy such as solar power

Reducing Emissions of Greenhouse Gases other than CO2

For greenhouse gases other than CO2, the Fujitsu Group mainly uses perfluorocarbon (PFC), hydrofluorocarbon (HFC), sulfur hexafluoride (SF6) and nitrogen trifluoride (NF3) at its semiconductor divisions. We have been continuously working on changing these gases to those with a lower global warming potential (GWP) and installation of equipment to remove harmful materials in our new and existing fabrication lines.

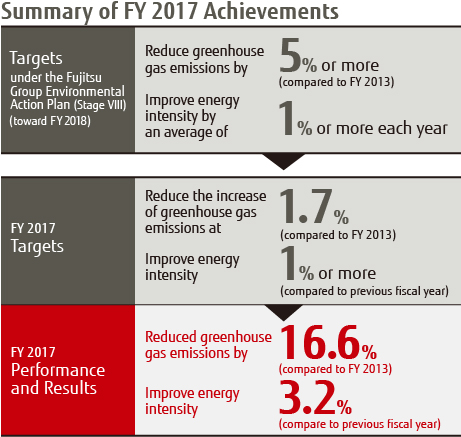

FY 2017 Performance and Results

Promoted Reductions of CO2 Emissions Accompanying Energy Consumption

In FY 2017 as well, we are introducing and upgrading BAT* at each business site, streamlining manufacturing, making energy consumption "visible," and utilizing measurement data, etc.

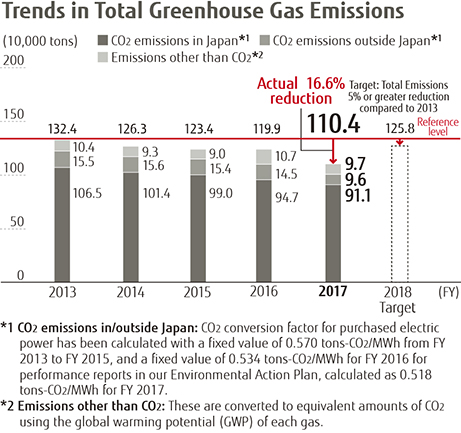

GHG emissions in FY 2017 totaled approximately 1,104,000 tons (specific consumption/sales revenue: 26.9 tons/100 million yen), down 16.6% since FY 2013. Although some of this decrease is attributable to factors such as transfer of business, we also implemented other measures to reduce by approximately 30,000 tons.

Additionally, energy intensity improved by 3.2% year on year. This is an annual average improvement of 1.4% from FY 2016 to FY 2017.

* BAT (Best Available Technologies):

Usable state-of-the-art technologies to reduce GHG.

Main Activities in FY 2017

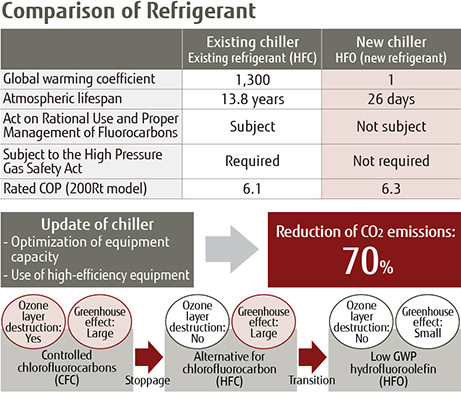

Installation of a High-efficiency Chiller for Significant Reductions in CO2 Emissions and Global Warming Coefficient

In FY 2017, Mie Fujitsu Semiconductor Limited updated our chillers for our office area. As a measure against climate change, we selected and installed a chiller which is effective in terms of both reducing energy and reducing refrigerant fluorocarbon load. By installing a high-efficiency inverter-type centrifugal chiller, we were able to reduce the amount of CO2 emission associated with energy consumption by 70% (CO2 reduction amount: 2,743 tons/year). Also, we now use hydrofluoroolefins (HFO) as new refrigerant, making it possible to reduce the global warming coefficient from the previous 1,300 times to 1 time (not subject to the Act on Rational Use and Proper Management of Fluorocarbons JAPAN).

By using this chiller, we are contributing to suppression of global warming caused by leakage of fluorocarbons at the time of installation or maintenance. We will continue to select and install environmentally-friendly equipment.

Inverter-type centrifugal chiller

Inverter-type centrifugal chiller