Kawasaki, Japan, March 07, 2014

Fujitsu Laboratories Ltd. today announced that it has developed model predictive control technology specifically intended for supply chain management. Using this technology, it is possible to make successive revisions to plans based on multiple long-term forecasting scenarios and to respond to sudden changes in demand.

Big data has made it possible to forecast demand with increasing accuracy, but there is still a need to make better decisions for production quantities and order quantities in situations where demand often changes due to factors such as discount sales promotions or new product introductions. In such situations forecasting is considered to be unreliable and uncertain.

Fujitsu Laboratories has developed a model predictive control (MPC) technology, based on multiple forecasting scenarios, that looks ahead a certain amount of time to generate optimal ordering and production plans. Furthermore, by revising the forecasting model itself, it is possible to generate highly accurate planning made in response to sudden changes in demand.

This technology can be used, for example, to optimize inventories based on demand forecasts for retail store operations, or to generate ordering plans that optimize profits even when demand changes suddenly. When verified with actual customer data, profits increased by an average of roughly 16%.

Background

In recent years, there has been a sudden emergence of tools for real-time collection, compilation, and analysis of huge volumes of data, such as data from product sales as well as social media and sensor data. The use of big data has come to be regarded as an important way to grow business and establish competitive advantage.

This includes putting machine learning, data mining and other predictive and analytic technologies to work together with optimization technologies to deal with enormous volumes of data. Technologies employing big data are increasingly seen as a way to assist with decision making in operations and management.

Issues

Although the accuracy of demand forecasting is improving thanks to the use of point-of-sale data, it is not easy to make accurate forecasts that take into account changes in demand that may arise from special sales or new product introductions. In such situations, it has been challenging to determine how best to use big data to make optimal decisions.

While it is possible to improve forecasting accuracy by using more sophisticated forecasting models that explicitly account for the factors underlying changes in demand, there is no way to completely eliminate the uncertainty in the forecast. Accordingly, it is important to make the best possible decisions while understanding the risks involved because of the inherent uncertainty of forecasts.

About the Technology

Fujitsu Laboratories has researched and developed optimal control methods for relevant models in the manufacturing domain, and, taking into account the unpredictability of models, has moved forward on the development of model predictive control technology that achieves optimal control in response to conditions that change minute-by-minute. This has been applied to fields such as energy management and engine control, where it has resulted in more efficient use of resources and improved performance.

In this instance, Fujitsu Laboratories applied its acquired model predictive control technology to retail supply chains. Responding to rapid changes in demand, and taking into account opportunity loss due to the cost of maintaining inventory and the cost of running out of stock, this technology achieved ordering plans that minimized total costs.

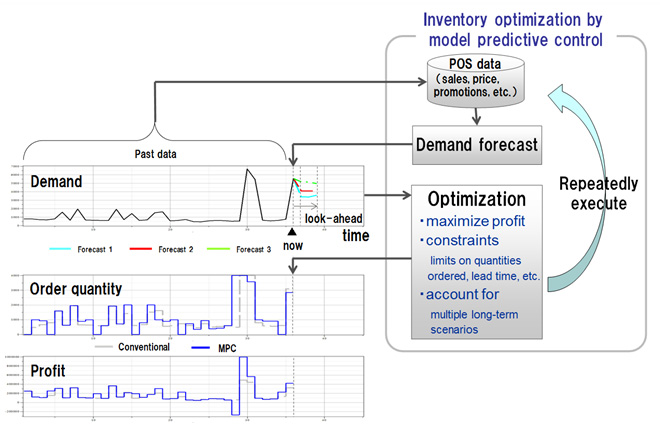

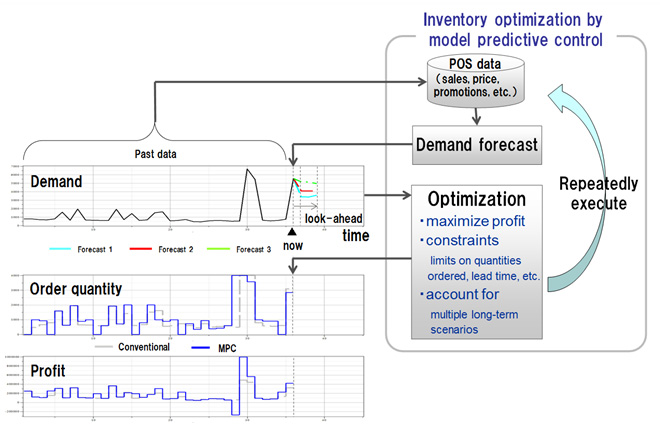

Key features of the new technology are as follows (Figure 1).

- Every time an order is placed, the system determines the optimal order quantity by performing an optimization calculation that attempts to maximize profit while minimizing total costs. These costs include the cost of carrying inventory and the cost of opportunity losses incurred by running out of stock, all under a set of constraints, such as shipment capacity, delivery time, and expiration dates.

- Order quantities are optimized over a fixed period that is based on a demand forecast that is successively revised.

- Order quantities are calculated to limit loss and maximize profits even under worst-case scenarios, by taking into account multiple long-term forecasting scenarios gleaned from big data.

By repeating the forecast/optimize cycle in steps 1 through 3 above, it is possible to automatically generate optimal ordering plans that respond to rapid changes in demand, all while taking into account the uncertainty in the forecast, a result that previously had been difficult to achieve.

Figure 1: Inventory optimization using model predictive control technology

Figure 1: Inventory optimization using model predictive control technology

This technology uses a calculation technique called mathematical optimization, which gets the best answer possible by following the rules that have been applied. In this instance, by varying the way it calculates the total cost and the constraints, it can generate ordering plans with flexibility.

Results

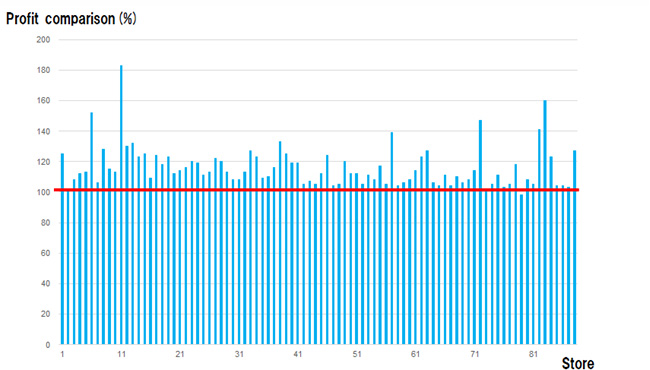

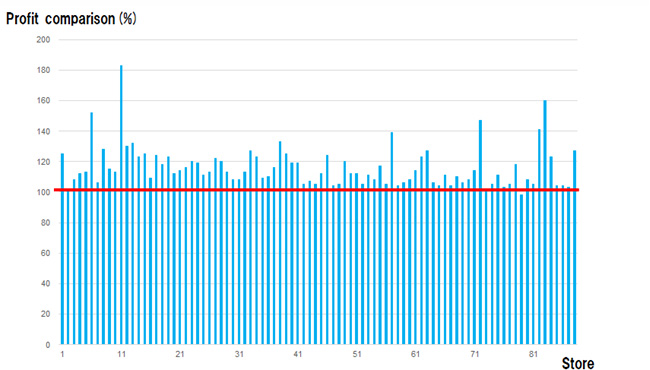

This technology was able to generate ordering plans that optimized retail inventory levels in a supply chain in a way that maximizes profit and responds to rapid changes in demand. When confirmed using actual retail store data across approximately 90 stores over a period of 60 weeks to generate ordering plans, this technology improved profits for all but one of these stores over conventional methods of determining order quantities via safe inventory amounts. In total, this technology increased profits by an approximate average of 16%.(Figure 2).

Figure 2: Results of inventory optimization using model predictive control technology(Profit comparison of each store: conventional method = 100%)

Figure 2: Results of inventory optimization using model predictive control technology(Profit comparison of each store: conventional method = 100%)

Future Plans

Today, Fujitsu Laboratories is developing a forecasting and optimization platform that assists with and automates decision making in operations and management by combining advanced forecasting and analysis technologies based on big data with optimization technologies, and is making it possible to create templates of analysis scenarios that combine forecasting and analysis with optimization, all on a single platform.

In the future, the company plans to incrementally incorporate an optimization technology based on the newly developed model predictive control technology into this forecasting and optimization platform, and position it as part of the FUJITSU Big Data Initiative set of products and services related to big data.

![]() E-mail: scm_mpc@ml.labs.fujitsu.com

E-mail: scm_mpc@ml.labs.fujitsu.com