Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Supply Chain Management

Socially Responsible Procurement Initiatives

In its quest to effectively promote CSR, the Fujitsu Group recognizes the crucial importance of initiatives across the entire supply chain, not just within the Group. To this end, we engage in CSR-based procurement activities together with our suppliers.

CSR Procurement Guideline

The Fujitsu Group proposes “Co-existence with Suppliers”, “Fair and Proper Evaluation and Selection of Suppliers” and “Promotion of CSR-Conscious Procurement Activities” as the procurement guidelines for its global procurement activities.

Regarding CSR procurement, in 2005 we formulated the "Fujitsu CSR Procurement Guideline", which sets out various requirements related to areas such as respect for human rights, labor, health and safety, and fair trade. Since then, we have periodically updated the Guideline while asking suppliers to comply with it. Fujitsu become a member of the Responsible Business Alliance (RBA)(*1) in 2017 and adopted the RBA Code of Conduct as the "Fujitsu CSR Procurement Guideline" in March 2018. Suppliers are subject to the Guideline if they provide components, materials, construction services, equipment, software, and so on for use in Fujitsu Group products.

PRESS RELEASE: Fujitsu Joins EICC, a Global Corporate Social Responsibility Coalition

http://www.fujitsu.com/global/about/resources/news/press-releases/2017/0329-01.html

(*1) The name was changed from Electronic Industry Citizenship Coalition (EICC) to Responsible Business Alliance (RBA) in October 2017

| FY | Policy / Measures |

|---|---|

| 2005 |

|

| 2007 | CSR surveys of suppliers begin |

| 2011 | Fujitsu CSR Procurement Guideline revised (addition of measures for conflict minerals) |

| 2015 |

|

| 2018 |

|

- Fujitsu Group Procurement Policy

http://www.fujitsu.com/global/about/procurement/policy/ - Fujitsu Group CSR Procurement Guideline

http://www.responsiblebusiness.org/media/docs/RBACodeofConduct6.0_English.pdf

The Fujitsu Group considers that the dissemination of CSR activities among its suppliers in the supply chain, as well as within Fujitsu, is essential to ensuring stable product supply and greater corporate competitiveness. Through close communication between Fujitsu and our suppliers at the management level, we require an understanding of the importance and necessity of CSR, working toward our goal of raising the level of CSR throughout the supply chain.

Promoting Activities and Participation in Industry-standard Initiatives (Membership of RBA)

In March 2017, the Fujitsu Group became a member of the Responsible Business Alliance (RBA), a global CSR alliance centered on the electronics industry. The RBA is a non-profit organization established in 2004 with the aim of supporting the rights and wellbeing of workers and communities worldwide affected by the global electronics industry supply chain. It currently has a membership of over 110 global companies, primarily made up of electronic device manufacturers and other ICT companies but also including retail, automotive and toy industry-related enterprises. The RBA's Code of Conduct stipulates standards to be observed with regard to labor, health and safety, the environment, ethical issues and management systems in the supply chain. The Fujitsu Group is engaged in group-wide CSR activities through the implementation of its own policy and principles in the FUJITSU Way. In future, Fujitsu will also respect the RBA Code of Conduct, redoubling its CSR efforts in its own supply chain and in those of its suppliers.

Within Japan, we also take an active role in the programs and initiatives of organizations such as the Japan Electronics and Information Technology Industries Association (JEITA) and work to promote socially responsible procurement throughout the industry.

Structures for Promoting CSR Procurement

Within the Fujitsu Group, relevant departments such as Human Resources and Labor Relations, Environment, Corporate Quality Management and Corporate Affairs all promote CSR activities under the company-wide guidelines established by the Responsible Business Unit. The CSR Reinforcement Department in the Corporate Purchasing Unit works with these and other relevant departments on CSR procurement to advance the cause of fair dealings with suppliers and CSR procurement along the supply chain. Through these promotional activities, we are integrating purchasing practices by our Fujitsu group companies both in Japan and overseas, driving socially responsible behavior back up the supply chain.

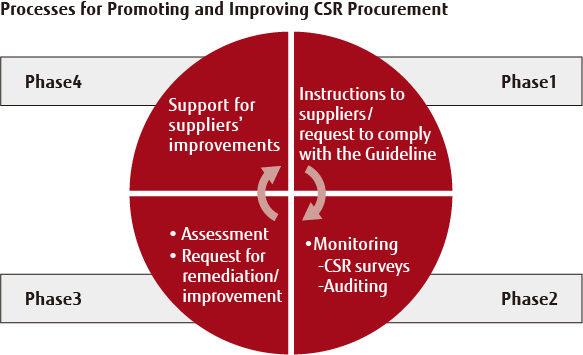

Processes for Promoting and Improving CSR Procurement

The Fujitsu Group is promoting CSR procurement activities among its suppliers to improve the implementation of CSR in its supply chain.

This begins with Fujitsu clarifying the compliance items through its CSR Procurement Guideline, and then requiring CSR activities of its suppliers. Subsequently, in order to confirm that CSR activities are being fully implemented by suppliers, they are asked to respond to a range of surveys on topics such as green procurement, information security and BCM.

The returned CSR survey forms are also subjected to diagnostic analysis. Fujitsu's Suppliers' Performance Review system then returns the results of the analysis, together with other evaluation items, to the supplier as feedback. If the supplier fails to meet Fujitsu's standards, they undertake to make improvements. Suppliers who are identified as requiring onsite observation undergo a CSR audit. Such suppliers are then required to submit a remediation plan for the items identified by the audit and Fujitsu works with the suppliers to make the necessary improvements. Fujitsu is engaged in ongoing improvement processes and promotion of CSR procurement with the goal that ultimately CSR activities will be properly undertaken by suppliers and will become firmly entrenched.

CSR Surveys and Audits

Supplier onsite audit in progress

Supplier onsite audit in progress

In order to check the status of suppliers' CSR-related programs, we conduct annual CSR surveys. In FY2017, we surveyed approximately 440 major suppliers in Japan and overseas using the CSR survey forms that were also used for overseas Group companies. Analysis of the responses revealed that 90% or more of our major suppliers are actively engaged in CSR activities. To further increase our familiarity with the CSR activities of our suppliers and boost the level of implementation, we are also surveying suppliers’ factories and requesting corrective action by any suppliers whose programs are lacking. We conducted onsite audits for nine suppliers in FY2017.

Evaluation and Remediation/Improvement Requests

In 1997, The Fujitsu Group introduced its Suppliers' Performance Review (SPR) system, a program that comprehensively assesses the procurement performance and basic profile of major suppliers as companies in terms of quality, technology, price, supply and CSR (Including environment). The results of the assessments are fed back to suppliers at venues, such as management meetings between both parties, in an effort to both remedy any issues and strengthen the partnerships. Especially for business partners whose quality, supply or comprehensive evaluation is less than the standard for two consecutive years, we call up our related departments and hold a discussion meeting on necessity of improvement request. For suppliers that we judged necessary improvement, we will implement measures such as request for drastic improvement and cease of new business.

This assessment program also acts as a channel for clear feedback on any issues identified during CSR surveys and audits, and for requests for corrective action or improvements.

Responsible Mineral Procurement

Fujitsu Group Responsible Mineral Procurement

Fujitsu Group regards the corporate responsibility for conflict minerals(*2) as one of the important CSR issues, and has established the "Fujitsu Group Policy on Conflict Minerals". Realizing that, in recent years, in addition to conflict minerals, the problem of "high-risk minerals" (*3) has grown at mineral mining sites around the world, where serious concerns over human rights violations such as labors under dangerous environments or child labor exist, we have revised our policy as "Fujitsu Group Policy on Responsible Minerals Sourcing" in March 2019.

(*2) Conflict minerals are the minerals whose mining or trading finances armed groups and fosters conflict, or that are closely related to such issues as human rights abuses or labor issues. The U.S. Dodd-Frank Wall Street Reform and Consumer Protection Act requires companies listed on U.S. stock exchanges to report the use of conflict minerals to the U.S. Securities and Exchange Commission (SEC). This applies to the minerals such as tantalum, tin, tungsten, gold that are mined in the Democratic Republic of the Congo or neighboring countries and any other minerals determined to be conflict minerals by the U.S. State Department.

(*3) Fujitsu Group defines tantalum, tin, tungsten, gold and cobalt as high-risk minerals.

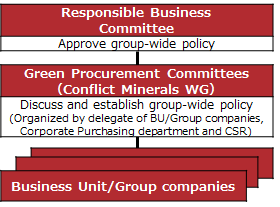

Structure for Addressing High-Risk Minerals

Fujitsu has established a structure including relevant internal departments under the jurisdiction of the Responsible Business Committee (chaired by the president). Through this structure, we conduct due diligence in the form of surveys of high-risk minerals in the supply chain. We strive to ensure transparency of procurement activities in the supply chain as well as responsible procurement of minerals.

Surveys on High-Risk Minerals

Referencing “The OECD Due Diligence Guidance for Responsible Mineral Supply Chains”, Fujitsu Group conduct high-risk minerals due diligence in the supply chain. In the survey, we use Conflict Minerals Reporting Template (CMRT) and Cobalt Reporting Template (CRT) developed by Responsible Minerals Initiative (RMI).”

Survey results

Fujitsu received replies from 87% of suppliers surveyed in FY2017. As a result of the survey, we confirmed 324 smelters, of which 252 companies complied with the RMI-certified Responsible Minerals Assurance Process (RMAP) evaluation protocol.

For suppliers who have not yet answered to our survey by the due date, we have reminded them of our request.

We checked the contents of the answers to the survey and asked our suppliers to resubmit the answers in case any incomplete items were found in the answers. We have also asked our suppliers to resurvey on the actual transaction situation if their smelters were pointed out as risky to use by our customers. Additionally, through our suppliers we asked the smelters who are not yet RMAP conformant to become RMAP conformant.

So far, none of the smelters our suppliers are using have been reported to have connection with armed groups but we will continue our smelter identification to further transparentize our supply chain.

Green Procurement, Information Security and BCM

Promoting Green Procurement

The Fujitsu Group has set out its basic approach to the environmentally sound procurement of components, materials and products in the Fujitsu Group Green Procurement Direction, and we are working with our suppliers to promote green procurement activities. We are also engaged in an initiative to reduce CO2 emissions in the supply chain. Specifically, the Fujitsu Group requests that all of its suppliers call on their own suppliers (companies at two removes from the Fujitsu Group) to reduce their CO2 emissions. The goal of the Fujitsu Group is to promote activities that reduce environmental impacts throughout the supply chain.

Promoting Information Security Measures

Based on the "Cybersecurity Management Guidelines" issued in December 2015 by Japan's Ministry of Economy, Trade and Industry and the Information-Technology Promotion Agency (IPA), the Fujitsu Group, along with its suppliers, has set the goal of "eliminating information security incidents", and is continuously implementing measures to prevent such incidents or recurrences thereof. These measures include education, awareness raising, auditing, and information sharing.

In recent years, there has been a significant increase in the commercial use of external services such as cloud computing and social networking services (SNS). There has also been a rapid increase in opportunities for the use of smart devices such as smartphones and tablet PCs. It is necessary to prevent not only emails sent by mistake and the theft or loss of PCs and smart devices, but also new kinds of risks involving information leaks such as internal crimes and cyber terrorism. In this context, when Fujitsu consigns work to suppliers, including offshore development work entrusted to overseas suppliers, it promotes education and awareness by requiring the same standards for information security management and the handling of personal information as it applies to itself. If any serious problem in information security comes to light at a supplier, or if the supplier fails to immediately implement corrective measures and no improvement is observed, Fujitsu will take steps such as reviewing its business relationship with that supplier.

| Initiatives | No. of participating/implementing companies |

|---|---|

| Information security briefings (Oct.-Nov. 2017)

(Locations: Sendai, Tokyo, Kawasaki, Chiba, Nagoya, Osaka, Takamatsu, Fukuoka, Okinawa) |

Approx. 1,100 staff from around 850 companies

|

| Written survey on the state of information security measures (Feb.-Mar. 2018) | Approx. 1,600 companies |

| Audit of the state of information security measures (on-site checking) (Apr. 2017-Mar. 2018) | Approx. 200 companies |

* Repeated status surveys, education and auditing of suppliers are fundamental to the maintenance of trouble-free operations.

Enhancing Supply Chain BCM

Fujitsu sees the enhancement of Business Continuity Management (BCM) throughout its supply chain as essential to ensuring a stable supply of products and services in the event of major disasters or other unexpected contingencies. Accordingly, since FY2007 Fujitsu has provided its suppliers with ongoing support to improve their BCM capabilities.

Each year, Fujitsu conducts a questionnaire-based survey of its suppliers on how they address BCM. In FY2017, we surveyed 860 suppliers, including some Group companies. We analyzed the results from around 2,277 sites (as of September 30) and provided feedback to the suppliers. Initially, Fujitsu formulated its own survey form, but in FY2013, an investigation subcommittee was established under the umbrella of the Japan Electronics and Information Technology Industries Association (JEITA) Materials Committee. This ledassembled product and component manufacturers to commence efforts aimed at standardization as an industry. Fujitsu also proactively participated in the planning of the subcommittee, progressing the formulation of a survey form that covered risk management items from the perspective of procurement with the focus on the supply obligations incumbent on suppliers. The completed form was made publicly available in September 2014 and has been used by Fujitsu since FY2014.

Fujitsu also conducts annual surveys of around 250 major solutions-related suppliers, analyzing the responses and providing feedback.

Communication with Suppliers

Business Meetings

Under the Suppliers' Performance Review (SPR) system discussed above, the Fujitsu Group holds management-level business meetings targeting around 200 of its major suppliers. These meetings provide both direct feedback on the assessment results in an interactive format as well as an explanation of Fujitsu's business outlook and procurement strategy. FY2017 marked the 54th such meeting. The feedback provided at these meetings also addresses CSR topics, and suppliers whose efforts do not meet Fujitsu's standards are asked to make improvements.

The assessment system for solutions-related suppliers established in 2004 was partially revised in FY2013 and is now used to evaluate around 1,300 companies. Of the companies surveyed, feedback on the results is provided to around 250 major suppliers.

Fujitsu Suppliers' Reception

Fujitsu Suppliers' Reception

Fujitsu Suppliers' Reception

The Fujitsu Group has been holding receptions for its suppliers since 1997. These receptions provide an opportunity for Fujitsu's President to summarize the progress of Fujitsu's business ventures and for the VP in charge of purchasing to explain Fujitsu's purchasing strategy. The gatherings are also used to present letters of appreciation to those suppliers who have made exceptional contributions to our business, and to strengthen our partnerships with suppliers.

The FY2017 reception was held in January 2018 and was attended by approximately 630 representatives from around 340 domestic and overseas suppliers. This year's event was also used to request that suppliers expand their CSR activities to their own upstream suppliers.

Procurement Compliance among All Suppliers

Education of Procurement Divisions

The Fujitsu Group is promulgating and promoting awareness of socially responsible procurement among its procurement division managers through initiatives such as education and training. In FY2017, in addition to CSR procurement and green procurement, education was also provided in the areas of risk management (BCM activities) and compliance with legislation such as the Subcontracting Law and Worker Dispatching Business Law. These educational programs will continue in FY2018 with the aim of further increasing the awareness of CSR among procurement managers.

Supplier Compliance Line

In August 2009, the Fujitsu Group established the Supplier Compliance Line as a channel for receiving reports from suppliers regarding any actions that are potential or actual instances of non-compliance in our purchasing activities. Channels were set up both internally and externally through which we can verify and investigate the facts of each report and respond quickly. Fujitsu's own internal reporting standards prohibit any adverse treatment of its own staff receiving such reports or those of suppliers making the reports.

Our agreements with suppliers also include explicit provisions on the elimination of anti-social forces and other such groups with the aim of preventing harmful actions by such anti-social forces (and avoiding any encouragement of their activities). The Fujitsu Group, including its suppliers, will have no relationship whatsoever with anti-social forces.