Archived content

NOTE: this is an archived page and the content is likely to be out of date.

Fujitsu Develops World's First Ultrafast 3D CAD Engine

Enables reliable system environment for machinery development by processing one million parts in 0.2 seconds

Fujitsu Limited,iCAD Limited

Tokyo, June 07, 2010

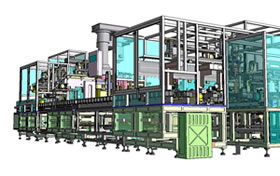

Fujitsu Limited and iCAD Limited today announced the development of the world's first computer aided design (CAD) engine, designed to be used as part of a 3D CAD system for designing machinery that is capable of processing data for one million parts in 0.2 seconds, in Japan.

The new engine features processing performance that is 200 times the speed of existing 3D CAD systems, giving it the power to process large-scale machinery with one million parts in only 0.2 seconds. Although the processing performance limitations of existing systems have traditionally forced engineers to design mechanical, electrical, and control systems using separate systems, the new engine enables the design of these elements to be consolidated into one system, streamlining the task of designing large-scale machinery.

In addition, the ability to share 3D data between departments, from design to manufacturing, prevents wasted effort and information discrepancies that can take place at each stage in the design process, thereby reducing the need for revisions during manufacturing, shortening development lead times, and increasing product quality.

This engine is to be incorporated into iCAD V7, which Fujitsu plans to release at the end of 2010.

Background

In the machinery industry, 3D CAD has become an indispensable tool in the race to quickly bring new, high-quality products to market. But given the massive volumes of data involved in designing large-scale machinery, coupled with limitations on the volumes of data that can be handled, engineers are forced to develop designs using simplified or segmented data. Furthermore, because of increasing data volumes of electrical and control system information including machining and assembly information, mechanical, electrical, and control systems must be designed using separate systems. As a result, when analyzing the consistency of machines as a whole and inspecting the actual equipment, engineers often need to make revisions or extend lead times.

In order to address these issues, Fujitsu has developed a 3D CAD engine that is capable of processing one million parts in 0.2 seconds. In the future, the company plans to incorporate the engine into its new iCAD V7 package.

Engine Features

The method typically used for representing 3D bodies on a computer is to split them into numerous small surfaces that approximate their intended shape. With large machinery, however, this greatly increases the volume of data that needs to be processed.

The new engine employs a new representation method that allows most of the parts of a machine to be precisely represented as mathematical expressions, making it possible to dramatically reduce the amount of memory required. This allows for a 200-fold increase in performance compared with the surface-approximation method.

- Handles designs for complex machinery with one million parts.

Machinery can include an extraordinarily large number of parts, exceeding the limits of conventional CAD tools that can only handle tens of thousands of parts. This engine can quickly process extremely large data sets composed of one million parts in only 0.2 seconds, making it possible to design an entire machine, or even relationships between multiple machines, without restrictions.

- Handles the design of mechanical, electrical, and control systems within a single system environment

Data volume limitations have traditionally forced designers to use separate systems to design a machine's mechanical components, electrical wiring, and control software. Using this engine, engineers are able to handle these design elements without any data restrictions using a single system, making it possible to control system costs. In addition, by utilizing unified design data to automatically connect wires and check their connections, the engine preemptively prevents oversights in wiring installations and misconnections, reducing the need for revisions during testing and greatly accelerating the testing cycle.

- Allows for pre-approval from manufacturing departments even during preliminary conceptual design

It was previously impossible to perform a design review using the 3D data for complex machinery. Instead, representatives from the design and manufacturing departments conducted hands-on testing with the actual machine. The product, which incorporates the new engine, will allow manufacturing departments to review and verify designs using 3D data before the designs are finalized, making it possible to conduct "digital reviews" that detect problems in advance that would otherwise only emerge during manufacturing. Because 3D data for the entire machine is kept consistent throughout the design phase and is shared between design and manufacturing departments, the development lead time can be reduced.

Enhancement of Fujitsu's CAD Business

Fujitsu has recently added to its PLM(1) Business Center, a team to enhance the promotion of CAD products. It has also deployed technical staff to iCAD, which is in charge of product development, who will provide support for business deals involving CAD products. This program, along with approximately 1,000 staff from Fujitsu's offices across Japan and its sales partners in the manufacturing sector, will serve to enhance sales and promotional activities for products based on the new engine (scheduled for the end of 2010).

Sales Target

8,000 units during FY2011 (ending in March 2012).

About Fujitsu

Fujitsu is a leading provider of ICT-based business solutions for the global marketplace. With approximately 170,000 employees supporting customers in 70 countries, Fujitsu combines a worldwide corps of systems and services experts with highly reliable computing and communications products and advanced microelectronics to deliver added value to customers. Headquartered in Tokyo, Fujitsu Limited (TSE:6702) reported consolidated revenues of 4.6 trillion yen (US$50 billion) for the fiscal year ended March 31, 2010. For more information, please see: www.fujitsu.com.

Press Contacts

Public and Investor Relations Division

Inquiries

Company:Fujitsu Limited

All other company or product names mentioned herein are trademarks or registered trademarks of their respective owners. Information provided in this press release is accurate at time of publication and is subject to change without advance notice.

This press release has been revised as of December 17, 2018.

Date: 07 June, 2010

City: Tokyo

Company:

Fujitsu Limited,

iCAD Limited,

,

,

,